Jaw crusher

Get Price Quote

We are offering jaw crusher. jaw crushers are used extensively throughout the aggregate and mineral processing industry. There two types of jaw crushers are available single toggle and double toggle. Single toggle jaw crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. Single toggle jaw crusher give higher percentage of fines, hence usually used as primary crushing. In the other side our double toggle jaw crushers has forced oil lubrication with the oil pump and nozzles. It works with the help of two toggles, it generates fewer fines and particles then single toggle and come with sharp edges, therefore they are used mainly for making grits for road, railway track, civil construction etc. Both types of jaw crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction. working principle: crush tech, jaw crushers are equipped with one fixed and one moveable jaw plate, both of which support crushing jaw plates in several versions. The motor drives the belt pulley and the belt pulley drives the eccentric shaft to rotate, and make the moving jaw approach and leave the fixed jaw periodically, to crush, rub and grind the materials repeatedly, thus to make the material slower and slower and gradually fall down and finally discharge from the discharge opening. advantage: � jaw crushers are design in single toggle and double toggle � single toggle jaw crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. � single toggle jaw crusher give higher percentage of fines, hence usually used as primary crushing. � double toggle jaw crushers has forced oil lubrication with the help of oil pump and nozzles. � double toggle jaw works with the help of two toggles, it generates less fines and particles come with sharp edges, � both types of jaw crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction. application: stones, black trap, basalt, marble, quartz, granite, river gravel, coal, lime stone, mineral ore, making grits for road, railway track, civil construction etc.

Plastic Bottle Crusher Machine

150,000 - 200,000 Per Piece

Best Deals from Crushing Machine

Stone Crusher Plant

5,500,000 Per Set

1 Set (MOQ)

Plastic Crushing Machine

80,000 - 300,000 Per Piece

1 Piece (MOQ)

Pre Crusher

Get Price Quote

We are manufacturing pre-crusher machine with heavy duty construction for robust application in industries. This machine is also called as a primary crusher as well as lump crusher, its design with single shaft or double shaft construction The machine's crushing blades are made from very harden material like Mn. Steel, En material etc.....to suite with application. Separate drive given for double shaft crusher, so the blade crush the material with minimum friction. • Capacity Range: Up to 10 TPH • Size: 3400 to 1200 mm ApplicationsCoal, Chemical, Mineral, Ayurvedic herbs, hard & soft material as well as other allied industries etc.... Fab-Tech Manufactures:- " Roll Crusher, Roller Crusher, Double Roll Crusher, Smooth Roll Crusher, Crusher, Glass Crusher, Single Stage Roll Crusher, Two Stage Roll Crusher, Minerals Roll Crusher "

Vertical Shaft Impact Crusher

1,500,000 Per Piece

Stone Crusher Plant

Get Price Quote

Stone Crusher is the machine designed to reduce large rocks into smaller rocks. It is generally used to reduce the size of the rock. Different types of stone crusher can be used as a primary crusher or a secondary crusher depending on the application. Jaw crusher, Gyratory crusher, Cone crusher and Impact crusher are some of the highly used stone crushing machines in the mining industry.

Cone Crusher Liner

Get Price Quote

Jaw crusher

Get Price Quote

Techno Power engineering is leading manufacturer and exporter of Jaw Crusher in Ahmedabad. Jaw Crusher can crush toughest materials like granite, basalt, iron ore etc. The crushers have gained huge appreciation in the market for their host of qualitative features.A Hinge pin is placed on crushing chamber centerline for crushing without Rubbing, large bearings provided and integral lubrication With the low inertia of the mechanism only a light small diameter flywheel is required.Double toggles provide maximum leverage to long stroke eccentric Pull back and lifter springs automatically compensate for wear. Specifications: Feed Size: 125 mm to 1000 mm Capacity: upto 500 TPH

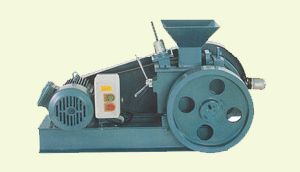

Hammer Crusher

Get Price Quote

Features: Crushers are used to reduce the material to a uniform size or to a graduation of size, for immediate use or for further processing. Though there are many types of crushers to be used depending on the application, We are manufactures Crushers for Fuel Handling Systems. We are manufactures Single rotor type Hammer Crushers, also known as Knittel.

DRUM BALER

Get Price Quote

hammer mill crusher

Get Price Quote

Automatic Coal Crusher

100,000 Per Piece

ice crushing machine

Get Price Quote

A Price industry is on the very well known for manufacturing high performance Ice Crusher in India and also exports it worldwide. We prince Industries are mainly focuses on customer satisfaction and after sell service. Ice crusher r is use for break down the ice slab in to small pieces of 50mm to 10 mm. Small pieces are use for getting best result in chemicals reaction or goods preservation. There are 3 models available with us which are giving here VIB-20 VIB-30 VIB-60 which having different production capacity by it size and capacity. Its production capacity is 3 to 10, 10 to 20 and 75 to 100 respectively.

Knittel Hammer Crusher

Get Price Quote

knittel hammer crushers involve the use of impact rather than pressure to crush material. Single rotor – hammer crushers are used for crushing run-of-mine coal, stone, ore, cullet and other difficult materials. They reduce large-lump materials to 6 to 8 mm size in one operation. These can be furnished with or without a metal trap for the removal of tramp iron or un-crushable lumps.

plastic crusher machine

Get Price Quote

Our ancillary products range also consist scrap grinder. Our plastic crusher machines are available in various design and models as required per capacity. We are supplying at lowest possible price to our clients.This machine is also known as plastic shredder, waste crusher. We are manufacturing from high quality material so our products are more durable and productive over time.

Jaw crusher

Get Price Quote

We provide our esteemed clients with high quality Jaw Crusher,Stone Jaw Crusher which is manufactured from best quality components for superior functioning. The Jaw Crusher that we provide is highly efficient and is manufactured with the help of cutting edge technology. Our Jaw Crusher Manufacturers are available at industry leading prices. Types available : Single toggle- having bearings with grease lubrication and higher percentage of finesAnd used as Pre CrusherDouble toggle- has forced oil lubrication with the help of oil pump and nozzles. it generates less fines and particles come with sharp edges, hence used mainly for making grits for road, railway track, civil construction etc Attributes : EconomicalHighest ratio of size reduction Applications : StoneVarious MineralsCoalOres etc Technical Specifications ModelSize of CrusherMax. Feed *Motor H.PRPMInches mm.JP - 08048" x 4"200 x 100 3"5280JP - 100610" x 6"250 x 150 5"10280JP - 120712" x 7"300 x 175 6"15325JP - 160916" x 9"400 x 2258"25325JP - 201020" x 10�500 x 2509"30325JP - 300930" x 09"750 x 2258"30325JP - 301530" x 15"750 x 37514"40325JP - 360836" x 08"900 x 2007"50300JP - 362036" x 20"900 x 50016"60300JP - 362436" x 24"900 x 60021"75300

Jaw crusher

Get Price Quote

We are offering jaw crusher. Ours is an eminent organization, engaged in manufacturing and supplying jaw crusher. Offered jaw crusher is used for crushing material and is developed in adherence with the guidelines laid in the industry to attain highest benchmarks of quality. Driven by motor, our offered machines are offered to our customers at industry leading prices. features: reliable operation easy maintenance low operating cost specifications: capacity(th): 140-260th electric motor power: 110kw Features: Our jaw crusher has Simple structure and reliable operation Easy maintenance and low operating cost Rugged Steel Body Jaw Plates of Wear-Resistant Manganese Steel Special Steel Eccentric Shaft with Heavy -Duty Double-Toggle Attachment Superior load distribution Spray Oil Lubrication System Guarantees safe operation at high speeds. Requires lower horse power cheaper squirrel cage Maximum Crushing Range-13MM to 62MM

Jaw crusher

155,000 Per unit

Laboratory Jaw Crusher

Get Price Quote

Laboratory Jaw Crusher is designed to speed up the crushing of aggregate, ores, minerals, coal, coke, chemicals and other similar materials. It is compact and of rugged construction for general laboratory. Two jaws of manganese steel are provided in the jaw crusher. The moveable jaw produces two blows for every revolution, thus reducing over sizing to a minimum. A combination of forward and downward and strokes with a rocking action experts pressure on the coarse material to pass through the jaws. A hopper is provided at the top for feeding materials. The smooth jaw ensure a uniform product and easy cleaning is possible.

Lump Crusher

Get Price Quote

Lump is fed from the top. Wide flanged inlet area is for accommodate a greater mass. It has single shaft with evenly placed impacting fingers and fix comb on body. Shaft with Lump is brake between rotating finger and fix comb. Broken lumps are collected from bottom.It has single shaft supported on flange mounting bearings. Bearings are bolted on fabricated body. bars (fingers) are fixed at evenly placed on shaft. Similar size bars are fixed one side-wall of body. Bars on shaft and on body are staggered to each other. Shaft is driven through motor and pulleys. Fabricated body fixed on base frame. Rubber tyres are fitted at bottom of frame to move unit easily, where every you need.

coal crusher machine

Get Price Quote

agriculture plant machinery, ground cracker machine

Jaw Crusher Laboratory

Get Price Quote

Introduction Laboratory Jaw Crusher is designed to speed up the crushing of aggregate, ores, minerals, coal, coke, chemicals and other similar materials. Its compact and of rugged construction is advantageous for general laboratory or small pilot plant operations.wo jaws of manganese steel are provided in the jaw crusher. The moveable jaw produces two blows for every revolution, thus reducing over sizing to a minimum. A combination of forward and downward and strokes with a rocking action exerts pressure on the coarse material to pass through the jaws. A hopper is provided at the top for feeding materials. The smooth jaws ensure a uniform product and easy cleaning is possible. Max Size of feed 50mm (approximately) Product discharge Size of feed 6mm to 18mm (adjustable) Capacity 80kG/hr (approximately - based on material) Operation On 440 volt, 3 Phase, 50hz, A.C. supply with 3H.P. Electric motor motor, a starter ' v ' belt pulley drive and mounting

Automatic Stone Crusher

20,000 Per unit

1 unit (MOQ)

ice crushing machine

Get Price Quote

The machine is mounted on a frame made from MS channel. The frame has two rubber wheels and fixed supports for easy transportability and it can be moved by one man from place to place, if required. The rotating drum with spikes rotates on two heavy duty self aligning ball bear-ings.

Fruit Crusher Machine

38,440 Per Piece

1 Piece (MOQ)

Drum Crushers

Get Price Quote

Drum Crushers are ideal for pressing light metal & rolled hoop barrels. The surrounding spray guard with a large viewing window represents the concept of optimum safety. Front door of the crusher can be provided as sliding door type or hinge door type as per customer's requirement. These balers can be either operated by hand lever or by electrical push buttons. Salient Features: Energy saving, quite and vibration free operation. 2- stage hydraulic with automatic stop at end of cycle. Fluid collection unit can be connected to a disposal system. Venting spikes pierce holes in drum top for air ventilation. Surrounding spray guard with viewing window for operator's safety Sturdy, enclosed welded steel construction Maintenance free press Press ram guide moves during pressing to reduce wear, saving subsequent cost

sugarcane machine

118,000 Per Piece

Hammer Crusher

195,000 Per Piece

sugarcane machine

49,999 Per UNIT