Wood Crushing Machine

100,000 - 400,000 Per Piece

1 Piece(s) (MOQ)

Stone Crusher Machine

45,000 - 55,000 Per Set

1 Set (MOQ)

Best Deals from Crushing Machine

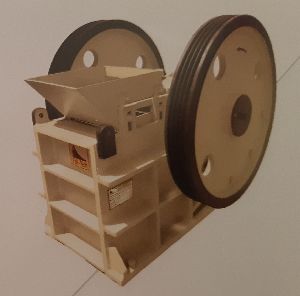

Jaw Crusher

Get Price Quote

Details We manufactures two types of Jaw Crusher, Single toggle and Double toggle. Single toggle Jaw Crusher have simple and robust construction with grease lubricated bearings design, which is easy to maintain and economical. This machine gives higher percentage of fines. Double toggle Jaw Crushers has forced oil lubrication with the help of oil pump and nozzles, the machine works with the help of two toggles, so that it’s generates less fines and particles come with sharp edges.

Used Stone Crusher Plant

Get Price Quote

1 piece (MOQ)

Food Waste Crusher Machine

24,799 - 24,800 Per piece

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

hammer mill crusher

250,000 - 500,000 Per piece

1 piece (MOQ)

The hammer mill is an essential piece of equipment used in various industries for grinding and pulverizing materials into fine particles. With its robust design and high processing capacity, it is particularly effective for handling grains, spices, chemicals, and other bulk materials. Hammer mills are renowned for their ability to reduce particle size through the impact of high-speed rotating hammers, making them a valuable asset in both manufacturing and processing environments. Versatile Grinding Capabilities Hammer mills are capable of grinding a wide range of materials, including grains, biomass, plastics, and minerals, allowing for diverse applications across various industries. High Throughput Designed for efficiency, hammer mills can process large volumes of material quickly, making them ideal for high-capacity production environments. Adjustable Particle Size The fineness of the output material can be easily adjusted by changing the screen size, enabling precise control over the grinding process to meet specific requirements.

Stone Crusher Metal Detector Machine

100,000 Per piece

1 piece (MOQ)

Plastic Crushing Machine

80,000 - 300,000 Per Piece

1 Piece (MOQ)

plastic crushing machinery

90,000 - 750,000 Per piece

1 Set (MOQ)

ice crushing machine

Get Price Quote

Skytech Kitchen Equipment Co. is supplying broad range of Commercial Kitchen, Refrigeration, Bakery and Imported Kitchen Equipments in India along with unmatched our equipments quality and unbeatable price in each sector of hospitality. Sky-Tech Kitchen Equipment co. is established by strong enthusiasm with highly creating passion. Sky-Tech Kitchen Equipment co. is starting through a some small & medium project. Through the time established & development by our self-motivation capability .So Sky-Tech Kitchen Equipment Co. achieved more & more good result achievements. Sky-Tech Kitchen Equipment co. experience time pass from Studies & actions. It has taken for our self the valuable thing that each company only can be killed and will be developed if it brings suitable value customers, social and each company staff. Each people are free to make their idea with highest Responsibility. Sky-Tech Kitchen Equipment co. is trying our best to be the leading company in the business field. Our workmanship is marked by our unwavering commitment to quality & working with our client’s suppliers, distributors and employees as a team. Since our inception Sky-tech kitchen equipment company has focused on the vision of helping on client respond to the key dynamics that driving their company development. Sky-tech Kitchen Equipment co. have engaged in Manufacturing & Exporting of Refrigeration Equipment, cooking Equipment, Preparation Equipment, Washing equipment, storage Equipment, Services Equipment, Air handling Unit, Duct Work, and Gas Pipeline Work, so sky-tech Provide complete solution of Hospitality. Sky-Tech operated Turnkey base project such as Institutional mess, Hostel, Banquet, resorts, hotels, Restaurant, Defence mess, and Industrial Mess, Hospitals, so Sky-tech manufactured Customised product aspire requirement.

Jaw Crusher

Get Price Quote

Apollo jaw crusher modal b1250 250 tph .

Stone Crusher Plant

Get Price Quote

Stone Crusher is the machine designed to reduce large rocks into smaller rocks. It is generally used to reduce the size of the rock. Different types of stone crusher can be used as a primary crusher or a secondary crusher depending on the application. Jaw crusher, Gyratory crusher, Cone crusher and Impact crusher are some of the highly used stone crushing machines in the mining industry.

Jaw Crusher

Get Price Quote

We are offering jaw crusher. jaw crushers are used extensively throughout the aggregate and mineral processing industry. There two types of jaw crushers are available single toggle and double toggle. Single toggle jaw crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. Single toggle jaw crusher give higher percentage of fines, hence usually used as primary crushing. In the other side our double toggle jaw crushers has forced oil lubrication with the oil pump and nozzles. It works with the help of two toggles, it generates fewer fines and particles then single toggle and come with sharp edges, therefore they are used mainly for making grits for road, railway track, civil construction etc. Both types of jaw crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction. working principle: crush tech, jaw crushers are equipped with one fixed and one moveable jaw plate, both of which support crushing jaw plates in several versions. The motor drives the belt pulley and the belt pulley drives the eccentric shaft to rotate, and make the moving jaw approach and leave the fixed jaw periodically, to crush, rub and grind the materials repeatedly, thus to make the material slower and slower and gradually fall down and finally discharge from the discharge opening. advantage: � jaw crushers are design in single toggle and double toggle � single toggle jaw crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. � single toggle jaw crusher give higher percentage of fines, hence usually used as primary crushing. � double toggle jaw crushers has forced oil lubrication with the help of oil pump and nozzles. � double toggle jaw works with the help of two toggles, it generates less fines and particles come with sharp edges, � both types of jaw crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction. application: stones, black trap, basalt, marble, quartz, granite, river gravel, coal, lime stone, mineral ore, making grits for road, railway track, civil construction etc.

DRUM BALER

Get Price Quote

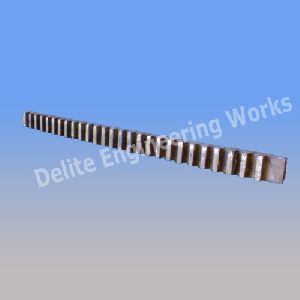

Coal Crusher Screen Bar

Get Price Quote

sand reclamation plant

150,000 Per Piece

Jaw Crusher

500,000 - 5,000,000 Per set

15 Set (MOQ)

Hammer Crusher

Get Price Quote

Features: Crushers are used to reduce the material to a uniform size or to a graduation of size, for immediate use or for further processing. Though there are many types of crushers to be used depending on the application, We are manufactures Crushers for Fuel Handling Systems. We are manufactures Single rotor type Hammer Crushers, also known as Knittel.

Pre Crusher

Get Price Quote

We are manufacturing pre-crusher machine with heavy duty construction for robust application in industries. This machine is also called as a primary crusher as well as lump crusher, its design with single shaft or double shaft construction The machine's crushing blades are made from very harden material like Mn. Steel, En material etc.....to suite with application. Separate drive given for double shaft crusher, so the blade crush the material with minimum friction. • Capacity Range: Up to 10 TPH • Size: 3400 to 1200 mm ApplicationsCoal, Chemical, Mineral, Ayurvedic herbs, hard & soft material as well as other allied industries etc.... Fab-Tech Manufactures:- " Roll Crusher, Roller Crusher, Double Roll Crusher, Smooth Roll Crusher, Crusher, Glass Crusher, Single Stage Roll Crusher, Two Stage Roll Crusher, Minerals Roll Crusher "

Sugarcane Crusher

16,000 Per Piece

We are one of the prominent manufacturers of sugar cane crusher, which is utilized in crushing sugarcane and extracting juice from it. These sugar cane crusher find an extensive application in sugar and jaggery plants

Double Toggle Jaw Crusher

Get Price Quote

1 Piece (MOQ)

Mild steel fabricated crusher body is strengthened to withstand heavy load. Main (Eccentric) shaft is running on antifriction bearings. Jaw plates and chick plates are made from highly wear resistance manganese steel. Oscillating Jaw is fabricated from mild steel, which is fitted on main shaft. Both flywheels are work as pulleys. Flat OD wheel is for flat belt drive and V-grooved wheel is for V-belt drive. Out let gap can be varied easily by add OR remove mild steel plates between toggle plate and main body. GREENFIELD jaw crusher is Heavy duty with robust design single toggle Jaw Crusher. It is for Crushing wide variety of hard material. Material can be crushed are Lime Stone, Marble, Granite, Rock, Dolomite, Bentonite, Coal, Ferro-Alloys etc.

brick crushing machine

Get Price Quote

Brick Crushing Machine is manufactured using super grade components and ultra modern techniques in observance to set industry standards. Machine offered in different specifications to meet exact demand of clients in specified manner. Features : Robust construction High productivity Durability Importance : Brick crusher is very useful for crushing wasted bricks into pieces which can be further used for other construction work. It is incorporated with heavy duty plates and main shaft, delivers high output in very short time. The product is capable of producing brick pieces of different sizes according to customer requirements. Offering Bricks Crusher : Bricks crusher is very useful for crushing wasted bricks, into small pieces, which can be used for other construction work. Incorporated with heavy duty plates and main shaft (crushing unit), machine delivers very high output, in short time. Moreover, it is capable of producing brick pieces of different sizes according to customer's requirement. For more information, please feel free to contact us.

battery operated sugarcane crusher machine

55,000 Per PER PIECE

1 Piece (MOQ)

Cone Crusher Liner

Get Price Quote

Jaw Crusher

Get Price Quote

Techno Power engineering is leading manufacturer and exporter of Jaw Crusher in Ahmedabad. Jaw Crusher can crush toughest materials like granite, basalt, iron ore etc. The crushers have gained huge appreciation in the market for their host of qualitative features.A Hinge pin is placed on crushing chamber centerline for crushing without Rubbing, large bearings provided and integral lubrication With the low inertia of the mechanism only a light small diameter flywheel is required.Double toggles provide maximum leverage to long stroke eccentric Pull back and lifter springs automatically compensate for wear. Specifications: Feed Size: 125 mm to 1000 mm Capacity: upto 500 TPH

Sugar Cane Crusher

Get Price Quote

dev exports has been recognized as the leading company, exporting high tech sugar cane crusher to various parts of the world. We are presenting hydraulic sugar cane crusher which is accompanied with innovative sealed oil bath lubrication system for gear box that provide safety and ensures least maintenance. Being one of the dependable sugar cane crusher machine exporters we provide only robust sugar cane crusher machines which are made of special steel. Our sugar cane crusher is a technologically sound product, comprising unique built in gear box. features : innovative sealed oil bath lubrication system for gearbox, which provides safety and requires less maintenance. extra large master gear of gearbox for easy and smooth operation, which avoids motor or engine loading. the unique coupling of gearbox safeguards parts and provides personal safety, in case of extra load the coupling breaks to guard parts. same stud and brass are used thought out the crusher, so less spares required. no need of concrete foundation. It can be placed on a plain surface. It can be moved easily and place can be changed. all parts are made of special steel. novel scrapper system keeps crusher clean and provides clean juice. our sugarcane crusher extracts maximum juice and provides maximum safety. this efficient design of crusher is evolved after years of research and development. models are available for various crushing capacities.

brick crushing machine

Get Price Quote

Sugar Cane Crusher machines

Get Price Quote

We the leading Manufactures,Suppliers and Exporters supply Automatic 3 Roller Stationary Model Sugar Cane Crusher machines. Fabricated using high grade stainless steel, these machines have transparent and hygienic extraction process without any need of human intervention at any stage. Furthermore, the sugarcane juice can be seasoned with juice extracts from lemon, ginger and mint. These easy and safe to use machines have wheel mounted on them for moving from one place to other. Apart from these, these also have covered waste bin. Features Noise free Free from rust Cleaning is very Easy Technical Specification -Crushing Capacity: 60 kg/hr (Approx.) -Required power : 0.5 HP, 240 V, 50 Hz -Dimension: 47 x 56 x 135 cms (Approx.) -Net Weight : 97 kg (Approx.)

slag crushing machine

1,200,000 Per Piece