crystallizers

Get Price Quote

We are offering crystallizers. Crystallization is the (natural or artificial) process of formation of solid crystals precipitating from a solution, melt or more rarely deposited directly from a gas. Crystallization is also a chemical solid–liquid separation technique, in which mass transfer of a solute from the liquid solution to a pure solid crystalline phase occurs.

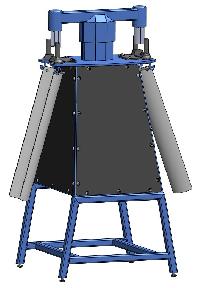

WORM WHEEL CRYSTALLIZER

Get Price Quote

Best Deals from Crystallizers

Planetary Crystallizer

Get Price Quote

We are a reputed Planetary Crystallizer Supplier in India. The Planetary Crystallizers offered by us are widely used in Sugar Mills for different applications. Specially designed for delivering consistent performance time after time, the Planetary Crystallizer is economical equipment for modern day production needs. Mounted In : Horizontal PositionVertical Position.

Static Crystallizer

Get Price Quote

Crystallization is an important unit of operation for manufacturing wide range of chemicals, which are ideal for use in pharmaceutical and chemical industries. The nature of a crystallization process is governed by both thermodynamic and kinetic factors, which can make it highly variable and difficult to control. Factors such as impurity level, mixing regime, vessel design, and cooling profile can have a major impact on the size, number, and shape of crystals produced. Crystal growth is a layer-by-layer process with less retention time. Crystallization equipment has been classified according to the means of suspending the growing product. Cooling Crystallizers : Static Crystallizers Draft Tube Baffle Crystallizers Evaporative crystallizers Forced Circulation Crystallizers Freeze crystallizers Melt crystallizers Oslo Crystal Crystallizers

Crystallizers, Pressure Vessel, Degerminator Machine

Get Price Quote

Optimizing the latest technology, we are involved in manufacturing a range of Crystallizers, Pressure Vessel and Degerminator Machines. These machines find application in various industries such as pharmaceuticals, fertilizers, agriculture, paper & pulp, power plant and construction industries. Made from graded material, our range of machines are robust in construction and are simple to install, easy to operate and highly energy efficient. Further, we also custom designed these machines as per the specific requirements of clients. We are engaged in customized fabrication and manufacturing of a high quality range of crystallizers, pressure vessel, de-germinator machine and custom fabrication & engineering. The world class infrastructure and fully automatic machinery helped us in delivering the high performance machinery. It is simple to install, easy to operate and highly energy efficient. These are fabricated using quality stainless steel in various configurations and capacities. Our range of machinery find application in various industries like pharmaceuticals, fertilizers, food & chemicals, agriculture, paper & pulp, power plant and construction industries.

Oslo Crystallizers

Get Price Quote

Oslo Type of Crystallizer is the oldest design developed for the production of large, coarse crystals. The design is based on desupersaturation of the mother liquor through contact with the largest crystals present in the crystallization chamber and keeping most of the crystals in suspension without contact by a stirring device, thus enabling the production of large crystals of narrow size distribution. How it works A bed of crystals is suspended in the vessel by the upward flow of supersaturated liquor in the annular region surrounding a central down-comer. Originally designed as classifying crystallizers, Oslo units are frequently operated in a mixed-suspension mode to improve productivity, although this reduces product crystal size. With the classifying mode of operation, hot concentrated feed solution is fed into the vessel at a point directly above the inlet to the circulation pipe. Saturated solution from the upper regions of the crystallizer, together with the small amount of feedstock, is circulated through the tubes of the heat exchanger and cooled by forced circulation of water or brine. In this way, the solution becomes supersaturated, although care must be taken to avoid spontaneous nucleation. Product crystal magma is removed from the lower regions of the vessel. Key Advantages Operating costs are much lower than that of any other type of crystallizer Low maintenance Allows long production cycles between washing periods

Crystallizer

Get Price Quote

Crystallizer, agitated netusche agitators dryer, agitated netusche filters

Industrial Crystallizer

Get Price Quote

Yogeshwar industries is crystallizer manufacturer in india. These crystallizers find application in various industries such as pharmaceuticals, fertilizers, agriculture, paper & pulp, power plant and construction industries.

Crystallizer

Get Price Quote

Crystallizer, WATER EJECTOR, steam ejector, Pump, Heat Exchanger

crystallizers

Get Price Quote

crystallizers, hydrogenators, Sulphuric Acid Plant, industrial fermenter

crystallizers

Get Price Quote

crystallizers, Evaporators, Power Plant Equipment