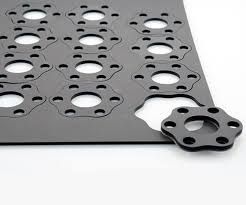

Laser Cutting Components

500 Per Piece

500 Piece(s) (MOQ)

We are the main supplier of this product.

Gear and Gear Cutting Components

Get Price Quote

Our gear units have quite a choice of gear-cutting and gear-forming techniques at their disposal, including hobbing, shaping, grinding, broaching, milling and rolling. Every production process is inevitably a compromise between ease of machining, good surface finish, profile accuracy, speed of output and economic production. All metal-removal operations leave minute ridges and scratches, caused by tool shapes or by the motion of rotary cutters; ‘perfect’ profiles and finishes are not obtainable with normal industrial processes. Tooling marks and deep scratches act as stress raisers, which occasionally lead to fatigue failure and tooth breakage. Such a failure almost invariably starts in the fillet radius at the root of a tooth, and may be caused by the use of a cutting tool with too small a radius. Most gears benefit from careful running-in under light load, since in this way the teeth acquire the surface finish needed for good lubrication and smooth running. In effect, they are given a final production operation, without which the process of surface failure might be initiated as soon as service operation begins. The life of a gear can also be limited by poor assembly. If a pinion is clumsily pressed onto a shaft, for example, it is likely to operate in an overstressed condition and fail at an early stage, even through running well within its designated rating.

Best Deals from Cutting Components

CNC Wire Cut EDM Components

Get Price Quote

sheet metal cutting components

Get Price Quote

sheet metal cutting components, auto mobile parts