Cyclone Dust Collector

50,000 - 150,000 Per Set

10 Piece (MOQ)

Construction : The cyclone dust collector is designed specially for high dust load ,high temperature, and product recovery applications. The primary component of the product are a fan, cyclone with a shutter , frame and bag filter. the support structure has wheel equipped with brakes for moving the cyclone dust collector. Cyclons dustcollectors is an air pollution control equipment used to remove large dust particals from indusrial process exhausts. Cyclone separator is also same and uses centrifugal forces to collect useful particals in product recovery. Both are one and same ,only application differs. Features : Low initial costs Low maintenance costs Less wearable parts Can work at high temperature application Applications : Sand blasting ,grit & short blasting Bag tube packers Belt conveyors Shake out conveyors Bins & bucket elevators Floor gate , grinders Mixers , foundry Food processing industry Paper & pulp industry

Cyclone Dust Collector

25,000 - 85,000 Per Piece

1 Piece (MOQ)

Best Deals from Cyclone Dust Collector

Multi Cyclone Dust Collector

300,000 Per Piece

1 Piece (MOQ)

Multi Cyclone Dust Collector

Get Price Quote

Buyers can avail themselves of high-quality Multi Cyclone Dust Collector at market-leading prices from us! We are standing amid the preeminent Manufacturers, Exporters, and Suppliers of Multi Cyclone Dust Collector from Gujarat, India. We lay emphasis on the quality of the product that we offer; and to ascertain that in a foolproof manner, we make it undergo stringent quality tests. Other than quality, our products are known for easy installation and low maintenance hassles. Details : In spite of what some would like us to believe, dust collection cyclones are simple tanks with no moving parts and have been used for dust separation for over seventy years. They are made up of just a few parts, an air inlet, an outer cylinder, an air outlet, and cone with dust chute that connects to a collection bin with flex hose. Dirty air comes in through an inlet and spins quickly around. This spinning throws the heavier particles outward to the cyclone walls. Airflow on the cyclone walls is slowed by friction. Particles get trapped in the slower moving air then gravity pulls them down. As the air continues to spin it slows and drops downward. The cone on the bottom of the cyclone forces that slowing air to keep the particles pressed tightly to the walls. Those particles continue to slide downward and eventually exit out a dust chute into the collection bin. The dust chute is sealed tightly to the bottom of the cyclone with no air leaks to stir up the collected dust. At a certain place inside the cyclone called a neutral point, the spinning clean air reverses direction and comes up through the centre of the cyclone then exits through the cyclone outlet. Salient Features : Easy installation Low maintenance cost Robust construction Compact

Cyclone Dust Collector

Get Price Quote

MAXTECH Cyclone Dust Collector are intended to accomplish high dust collection efficiencies at low weight drops. We can fulfill the most stringent air contamination control laws and/or item recuperation necessities. We can offer high proficiency Cyclones for particular applications of critical duty condition. SINGLE, TWIN and QUAD arrangements are accessible as standard configurations. Special arrangements can be supplied to meet your plant formats. Our basic dust containers and outlet plenums are specially crafted to suit every application. Our range of cyclone is the best solution for some dust collection needs, consolidating high proficiency, low maintenance costs, effortlessness, low pressure drop and well demonstrated bit of equipment. We offer an assortment of arrangements, for example, individual, arrangement and parallel operations relying upon the application. Operating Principle: Dust-laden air enters the tube shaped body of the cyclones tangentially at the top the flow assumes a vortex design as it voyages helically descending. At the point when the particles achieve the divider, grinding gravity compel them to plunge release into a recipient. The centrifugal force from the air tangential velocity causes the heavier dust particles to move profoundly outward toward the cyclone's divider. The cleaned air spirals upward exit at the highest point of the cyclone. Boilers Building Products Cereal Cookers/Dryers Cupolas Crushers foundry grain cements boiler flue gas wood working dust Buffing dust Fly ash The unit essentially consists of a round and hollow and a cone shaped part. Dust and debris are sucked in at the top. Air containing fine clean extinguishes of the opposite side of the top, while the chips and large dust particles drop out of the base into a drum or a bin. The unit makes utilization of the centrifugal force for the particles' partition. The procedure drives the substantial particles to the base along these lines, making the air lighter to escape from the top. Unit must bay, which gives a stream pivoting development to the gas and subsequently the dust particles are driven towards the conceal surface where they are screwed down. Cyclone separators are devices that are utilized to particular dust from dust loaded gasses regularly when the dust molecule size is 20 microns or more. Filtration efficiencies in cyclones are not on a par with Bag Filters, however the upkeep expense of cyclones is much lesser than that of Bag Filters. Cyclones are additionally offered with exceptional wear liners and protections to suit your prerequisites and can be utilized for an extensive variety of uses in the accompanying industries.

Cyclone Dust Collector

95,000 Per Piece

Cyclone Dust Collector

Get Price Quote

Multi Cyclone Dust Collector

Get Price Quote

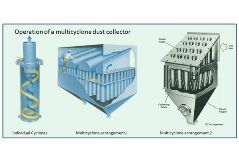

Mechanical gas-cleaning devices such as cyclone, multi Cyclones use centrifugal force as the primary collection parameter. Mechanical collection devices are widely used to collect particles from emission sources having high exit temperatures of sources with emissions containing particulates with a relatively large mean particle diameter (greater than 15 microns).

Multi Cyclone Dust Collector

150,000 Per Unit

J.D.Engineers offer high quality and high precision Multi Cyclone Dust Collector. Primarily used for dust separation, this collector is fabricated using qualitative components including an outer cylinder, an air outlet, air inlet and cone with dust separation wing, which is assembled Dust Separation Chamber. These Multi Cyclone Dust Collectors are made from very high quality raw material which ensures high durability at its user end. The design & sizes are various as per the volume of dust generated in the area. Multi Cyclone Dust Collectors are available at industrial leading prices.

Cyclone Dust Collector

Get Price Quote

We are engaged in building and offering high efficiency Cyclone Dust Collector. Leveraging on the expertise of qualified engineers, who have studied most cyclone designs and theories, we develop Cyclone Dust Collector, which maximize the working efficiencies. We perform extensive testing to determine the cone lengths so as to maximize the efficiency while complying with the plant restrictions. Moreover, these Cyclone Dust Collectors can be availed from us at the market leading prices. Applications Of Cyclone Dust Collector Used to remove dust and other product streams from processing operations Ideal for increasing the efficiency of a cyclone Efficiency Of Cyclone Dust Collector The manner in which the air and product enters the cyclone also affects the efficiency of Cyclone Dust Collector. We pioneered the concept of keeping the inlet centerline tangent to the outside edge of the cyclone. This smooth introduction reduces turbulence and increases efficiency of cyclones. The smoother the inside surface, the more efficient the cyclone. Along the same lines, perfect roundness maximizes efficiency. We employ state-of-the-art cutting and rolling equipment to ensure that the cyclones are perfectly round and symmetrical with smooth interior surfaces. Our process engineers have the experience and know-how to properly size and apply the same in making these cyclones. Air volume, density, temperature, humidity along with product characteristics sometimes create complicated sets of criteria. Our vast experience in designing systems with the assistance of our expert craftsmanship ensures that the clients receive cyclone that find use in diverse applications.

Twin Multi Cyclone Dust Collector

250,000 Per Piece

1 Piece (MOQ)

Multi Cyclone Dust Collector

Get Price Quote

Based in Ahmadabad, Gujarat we are one of the primary manufacturers and suppliers of Multi Cyclone Dust Collector. Our quality products are known to conform to international quality standards. The use of top-notch components makes it an effective tool for cleaning. Some of the industries where this machinery is used extensively are engineering, abrasive industry, foundry, pharmaceutical, rubber and food. Depending on the requirements of our clients, the machines can be customized and made available with different technical specifications.

CYCLONE

Get Price Quote

Cyclones are cylindrical chambers with a means of producing spiral flow at the top and a dust bin at bottom. These are primary collectors. Cyclones are useful for all processes such as gas cleaning, de-dusting, product recovery, pneumatic conveying etc. Cyclone with a pulse jet bag filter will offer long life to the bags and maximum efficiency of collection. Cyclones are classified as per the arrangement and number of shells. The unique helical cover high efficiency cyclonic collectors will separate dust particles from air stream with the impact of centrifugal force. Cyclones are designed for any capacity starts from 500m3/hr. Twin and quadruple arrangements are suggested to accommodate the size for bigger capacities from 25,000m3/hr. onwards. - Electrically efficient - Easy to maintain and operate - Effective for pollution control - Balance velocity

CYCLONE

Get Price Quote

Collect the dust & Shutter of filter to improve cotton quality & image

Cyclone Dust Collector

Get Price Quote

Cyclone dust collectors are the equipment of choice for many applications involving the collection of various sizes of dust particles. In some cases, cyclone dust collectors have been used as a pre-filter before a cartridge or baghouse collector, to out the larger, more abrasive dust particles that can easily damage standard media filters.

Cyclone Dust Collector

50,000 Per unit

Cyclone Dust Collector

250,000 Per Piece

Cyclone Dust Collector

Get Price Quote

We are instrumental in offering superior grade Multi Cyclone Dust Collector to the clients. Manufactured using premium grade raw material, these dust collectors are highly durable and possess resistance to adverse conditions. Offered range of dust collectors finds huge applications in plastic processing, pharmaceutical, powder coating, food processing plants, air conditioning plants, pneumatic transport of solids and cement & mineral. Multi Cyclone Dust Collector is a device to separate solids (in powder or granular form) from airgases. When the material is moving as in pneumatic conveying, the solids are separated. In this device, air is made to flow at cyclonic speed and made to rotate in a cylindrical vessel of suitable design. When the solid material attains high speed, it picks up centrifugal force and choose to cling to outer surface while air retains high speed it gets due to its velocity factor. Suddenly in the center, air outlet is provided for air to go out while due to centrifugal force the solid material is not able to change direction but goes downwards and gets separated.

Multi Cyclone Dust Collector

Get Price Quote

In spite of what some would like us to believe, dust collection cyclones are simple tanks with no moving parts and have been used for dust separation for over seventy years. They are made up of just a few parts, an air inlet, an outer cylinder, an air outlet, and cone with dust chute that connects to a collection bin with flex hose. Dirty air comes in through an inlet and spins quickly around. This spinning throws the heavier particles outward to the cyclone walls. Airflow on the cyclone walls is slowed by friction.

Multi Cyclone Dust Collector

Get Price Quote

Multi Cyclone Dust Collector, tank erection services

Cyclone Dust Collectors

Get Price Quote

Cyclone Dust Collectors, multiple options e-waste shredder machine

Multi Cyclone Dust Collector

Get Price Quote

Equipment used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas.

cyclone vacuum cleaners

Get Price Quote

cyclone vacuum cleaners, Robot Vacuum Cleaner, Wet Vacuum Cleaner

cyclone vacuum cleaners

Get Price Quote

cyclone vacuum cleaners, Vacuum Cleaner, Vacuum Cleaner

CYCLONE

Get Price Quote

CYCLONE, Ginning Machine Spare Parts, Floor Mounted Fan

CYCLONE

Get Price Quote

CYCLONE, Food Processing Machines, dal machines, ELEVATOR, Plan Shifter

CYCLONE

Get Price Quote

CYCLONE, ms hopper, Vertical Chemical Process Pump

CYCLONE

Get Price Quote

CYCLONE, Flaker machine, Double Cone Mixer, guar gum machinery

Industrial Cyclone

Get Price Quote

Industrial Cyclone, guar gum machine, Ultra Fine Pulverizer, Measuring Tank

Vertical Automatic Cyclone Dust Collector

Get Price Quote

Vertical Automatic Cyclone Dust Collector, motar