Industrial Distillation Plant

Get Price Quote

Industrial Distillation Column

40,000 Per Piece

1 Piece (MOQ)

Best Deals from Distillation Units

Flexo sdolvent recycling machine

151,000 Per per unit

our unique equipments are as below: . * 2632 varnish photo polymer plate making equipment * 3242, 4252, 4262 woven sack photo polymer plate making equipment * 4282, 5282 jumbo line flexo plate making equipment * rotary washout application: label . card , pad plastic sack , paper sack , flexible packing . aluminum foil , tissue , milk beverage , cartoon , preprint , cartoon, barcode , film , paper , corrugated board , paper carton , knitting bag , tetra etc..

Solvent Recovery Unit

Get Price Quote

Chemical free operation, simple, easy and savedigital timer for light finishing controlphilips uvc high intensity lamps equippedwith powerful air exhausting for big size models solvent recovery systems advantages : • reduce your solvent disposal costs and wastewater treatment surcharges • 1 year or better payback on most solvent recycling • equipment sized to meet the needs of small users, and the largest industrial plants. • with new, used, and refurbished options, we can usually find a system to fit your budget. • technical help with setting up and training to use the solvent recycling systems • we won’t forget you after the sale. # operating steps after opening the crate, plug in 220 v power, and connect the ground (earth). Open the lid and fill the tank up to the level with solvent to be recovered (80 l) close the lid and tighten it. Check all the pipe hose make sure it is well connected. Especially vacuum pipe (6) and fresh come-out pipe(1). Set up the thermostat(18) for example for perc.is 150 degree c, for green chemical is 160-210 degree c. Vacuum tank pressure(3) high at 0.03 mpa low at 0.01mpa, and steam cooling fan thermostat(11) at 40 degree c. Turn on the power switch(15), steam cooling switch(16), heater switch(17) and vacuum pump switch(12). If you want to be controlled with timer, it depends on the quantity of the chemical, set up the timer(14) then turn on the switch(13). # important install the unit in a wide and ventilated place disconnect electric power before doing any action no taking off the control panel change the diathermic oil every 1000 working hours no filling the solvent container up over the level (80 liters) remove the waste after every recovery process recovery time 3 o 4 hours

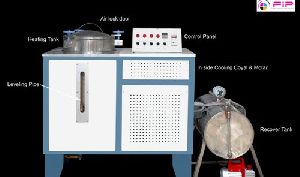

Flexo Green Chemical Recycling Unit

Get Price Quote

1 UNIT (MOQ)

Fipflexo For Flexo solvent recycling machine. Solvent Recycling Machine are distillers which allow the recycling and the re-use of degreasing and washing solvents.Through a simple distillation process, they separate the contaminants (resins, polymers, pigments, paints, oils, etc.) from the original solvent.The boiling of the solvent is accomplished by a peripheral heating jacket filled with diathermic oil, heated by an electrical element. The vapours are then convoyed to a condenser cooled by air or water. The condensed solvent is collected in a tank, for its reuse.

Multi Column Distillation Plant

Get Price Quote

Manufacturing high quality equipment multicolumn distilled water plant designed to produce 100% pyrogen free sterile distillate & chemically pure confirms to IPBPUSP standard. Multicolumn distilled water plant works on the principle of interstate heat exchanger, dramatically reduce the consumption of heating energy and cooling water. Thus enable to produce a large volume of pyrogen free distillate at a fraction of the cost than conventional systems. All documents related to factory acceptance test(FAT), Installation Qualifications(IQ), Operation Qualification(OQ), PQ are provided as part of the operational manual.

multicolumn distillation plant

Get Price Quote

Pharmaceutical Machinery, super heated water spray type sterilizer

Distillation Column

Get Price Quote

Yogeshwar Industries have generalized its deep knowledge and experience of their in-house professional engineers and offers a premise of building an excellent class of Distillation Column design that are utilized worldwide.

Kjeldahl distillation

Get Price Quote

Distillation Column

Get Price Quote

Made from grade stainless steel (304, 316), M.S., Hastelloy, Titanium and Nickel. our industrial distillation system is acknowledged for its durability. It is designed as per with industry standard as well as in accordance with client specifications. We offer wide array of industrial distillation system including primary condenser, secondary condenser, vent condenser, column, reboiler, product cooler, reflux drum and product receiver. Our array is known for efficiency, rugged construction, leak proof and crack resistance. Hence, the collection finds application in chemical and pharmaceutical industries

multicolumn distillation plant

Get Price Quote

Pure Sterile Pyrogen free distilled water conforming to USP standards. Compact in design. Electro polished creviceless inner contact surfaces. PLC based system for automated operation. Sanitary triclover fittings for quick and easy preventive maintenance.Double tube Sheet construction for the first column, where boiler steam is present. Synoptic panel board with facility for logging the data can also be given.

Distillation Plant

Get Price Quote

package boilers and pressure vessels, chemical plants

columns

Get Price Quote

columns, glass blown items, multi neck flasks, Industrial Stirrer

industrial distillation columns

Get Price Quote

industrial distillation columns, chemical dryers, Chemical Process Tank

steel columns

Get Price Quote

steel columns, Centering Plates, steel Products, steel h frame

distillery

Get Price Quote

distillery, filling, Labeling, Pharmaceutical, food, Soft Drink