Drum Blender

Get Price Quote

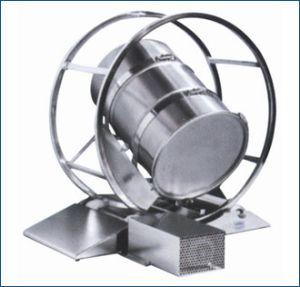

Drum Hoop Mixer

Get Price Quote

Our Drum Hoop mixer attachment is suitable for power and granule mixing. The Drum Hoop Mixer useful in research laboratory and also pharmaceutical, food, chemical and plastic fields having two parts, A. Main frame unit with Roller stand. B. Acrylic Mixing Drum with Rotating Arrangement. The Drum Hoop Mixer having drum capacity of 5 Kg. And operational capacity 2 to 3 kg. This Attachment is Suitable to Attached in our Both Main Drive.

Best Deals from Drum Blender

Drum Blender

Get Price Quote

Drum blender is staple machinery used in pharmaceutical and chemical industry. Drum mixers are highly efficient mixing equipment used for mixing of powders. These mixers have gallon drums which rotate in order to mix powder. The mixing process involves loading the material into the drum, which is secured in a hoop and rotated thereafter.This equipment is very useful for mixing of ingredients or raw materials to be dispatched in barrels. Unlike other mixers, this mixer does not have any internal moving parts like blades or impellers; so the mixer avoids deterioration of material from friction-induced heating, since the drum has no dead space, so the material is uniformly blended. The drum mixers are powered by pneumatic or electric motors and available in various sizes. These mixers are configured in such a manner so that proper mixing and quality control of the end product is attained.

Drum Hoop Mixer

Get Price Quote

Drum Hoop Mixer has been designed for mixing such as powder and granules. The Drum Hoop Mixer is equally suited to research as well as industrial use in the pharmaceutical, food, chemical and plastics fields. Drum Hoop Mixer comprises of two parts. 1. The Drive Unit with drum hoop support stands.2. Acrylic mixing drum with rotating fixture.The Drum Hoop Mixer is suitable for all main drive units.

Drum Hoop Mixer

Get Price Quote

Drum Hoop Mixer is suitable for power and granule mixing. The Drum Hoop Mixer useful in research laboratory and also pharmaceutical, food, chemical and plastic fields having two parts, Acrylic Mixing Drum with Rotating Arrangement.

Drum Hoop Mixer

Get Price Quote

Drum Hoop Mixer has been designed for mixing such as powder and granules. The Drum Hoop Mixer is equally suited to research as well as industrial use in the pharmaceutical, food, chemical and plastics fields. Drum Hoop Mixer comprises of two parts. 1. The Drive Unit with drum hoop support stands.2. Acrylic mixing drum with rotating fixture.The Drum Hoop Mixer is suitable for all main drive units.

Drum Blender

Get Price Quote

Design is cGMP – Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Available Capacity: 100 kg and 200 kg. This is a closed and contained system for blending and store. Main advantage of this system is that it is totally dust free. Controls panel with Cycle timer. Option for Variable speed

Drum Mixer Blender

Get Price Quote

Drum/ Barrel mixer is staple machinery used in pharmaceutical and chemical industry. Drum mixers are highly efficient mixing equipment used for mixing of powders. These mixers have gallon drums which rotate in order to mix powder. The mixing process involves loading the material into the drum, which is secured in a hoop and rotated thereafter. This equipment is very useful for mixing of ingredients or raw materials to be dispatched in barrels. Unlike other mixers, this mixer does not have any internal moving parts like blades or impellers; so the mixer avoids deterioration of material from friction-induced heating, since the drum has no dead space, so the material is uniformly blended. The drum mixers are powered by pneumatic or electric motors and available in various sizes. These mixers are configured in such a manner so that proper mixing and quality control of the end product is attained. salient Features : Design is cGMP - Current Good Manufacturing Practices compliance All Product contact parts AISI 316 & non contact parts AISI 304. Available Capacity: 100 kg and 200 kg. This is a closed and contained system for blending and store. Main advantage of this system is that it is totally dust free. Controls panel with Cycle timer. Totally dust free. Option for Variable speed. Safety Features : Interchangeable Product Container AC Frequency variable drive for product container. PLC Controls with HMI touch screen, Flame proof motor and Push Button station.

Drum Mixer Blender

Get Price Quote

Drum/ Barrel mixer is staple machinery used in pharmaceutical and chemical industry. Drum mixers are highly efficient mixing equipment used for mixing of powders. These mixers have gallon drums which rotate in order to mix powder. The mixing process involves loading the material into the drum, which is secured in a hoop and rotated thereafter. This equipment is very useful for mixing of ingredients or raw materials to be dispatched in barrels. Unlike other mixers, this mixer does not have any internal moving parts like blades or impellers; so the mixer avoids deterioration of material from friction-induced heating, since the drum has no dead space, so the material is uniformly blended. The drum mixers are powered by pneumatic or electric motors and available in various sizes. These mixers are configured in such a manner so that proper mixing and quality control of the end product is attained. SALIENT FEATURES : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Available Capacity: 100 kg and 200 kg. This is a closed and contained system for blending and store. Main advantage of this system is that it is totally dust free. Controls panel with Cycle timer. Option for Variable speed.

Drum Blender

Get Price Quote

Drum Blender, Lab Testing V Blender, Pharmaceutical Machinery V Blender

Drum Mixer Blender

Get Price Quote

Drum Mixer Blender, air jet cleaning machine, Packing Conveyor

Drum Mounting Blender

Get Price Quote

Drum Mounting Blender, Ice Cream Maker, Lab V Blender