dyeing jigger machine

Get Price Quote

1 Piece (MOQ)

DYEING JIGGER PROGRAMMER

4,000 - 7,000 Per PIECE

1 Piece (MOQ)

Electrocom offers Jigger Programmer used at Jigger Dyeing Machine in Textile Mills , textile processing industry . Jigger Dyeing machine is used for cotton, linen etc dyeing and bleaching process. It Is most common , efficient and useful device used at Jigger Dyeing Machine. Controlling and display of cycle counts , run counts, direction of fabric rotation , loading and unloading etc are some important work functions of Jigger programmer. It is advance microprocessor based dyeing automation system to improve performance of jigger dyeing process. Reduction of Time Wastage , Maintaining cycle frequency and easiness in operation can be achieved by this unit. Application in Industries - Machines: Textile Mills, Dyeing House, Process House , Jigger Machine, Textile Machinery Usefulness of Jigger Programmer unit at Jigger Machine Improvement & Maintaining of Dyeing quality Machine Efficiency Improvement – Production Rise Man Power Cost Reduction Auto Loading & Unloading Alert at End of Programme

Best Deals from Dyeing Machine

H.T.H.P. BEAKER DYEING MACHINE

Get Price Quote

We offer you an H.T.H.P. Beaker Dyeing Machine embedded with microprocessor to ensure the temperature control during the sample testing. This machine includes beaker, tank and gear box to accomplish the comprehensive testing process. The core benefit of the H.T.T.P. Beaker Dyeing Machine is you can perform dyeing of fabric and yarn at atmospheric pressure also. While you are performing a dyeing with this equipment, maintaining a very specific condition is demanding to ensure the fixation of dye molecule on the fabric or yarn.

Bowl Mangle Drying Range

651,000 - 725,000 Per Sets

Bowl Mangle Drying Range High quality Textile Processing Machinery like Bowl Mangle Drying Range with heavy duty equipment. Cloth Entry: A Set of three curved bar rubber sleeve expander. A pair of mechanical cloth guider with adjusting frames to suit cloth width. Structure: M.S. Stack fabricated from M.S. Plates and flates. All type of Textile Machinery Spare Parts Manufacturer with high quality material

hank yarn dyeing machine

2,650,000 Per Piece

Hank yarn dyeing machine.for.viscose yarn,cotton yarn,silk yarn,acrylic yarn.

Automatic Jigger Machine

500,000 - 5,000,000 Per Piece

01 piece (MOQ)

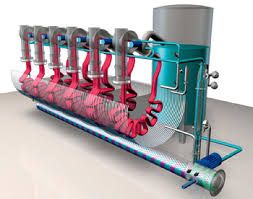

Fully Automated Atmospheric Jigger machine is one of the most technologically advanced automated machines for dyeing and bleaching to give you the most natural, highly accurate, even results through the batch. It consists of Two main rollers, each with an independent yet synchronous driving force coupled with constant and regulated tension control system allows constant dyeing and liquor ratio throughout the width of the Fabric. Horizontally fitted spray pipes all across the width expedite the fabric rinsing. Pneumatically sealed doors minimise the heat loss, keeps the temperature uniform, reduces the exposure of liquor and cloth to the air. Throughout the process, the fabric speed and metering, smooth and jerk-less stop and start, gradual noiseless reversal, and automatic temperature regulation provide uniformity in fabric and the process.

Jigger Machine

Get Price Quote

We Manufactures Jigger Machine Spare Parts.Jigger Machine Spare Parts offered by us are manufactured using high-grade components and spare parts that are sourced from vendors of high, Brake Drum 10" OD Ratchet & Paul Type complete with, Liner Shoe Locking Spring, Hand Wheel, Screw etc.(Rate per set).

continuous dyeing machine

Get Price Quote

Features: Detangling Unit with Positive Feeder Set of Padding Mangles Pre Dryer & Steaming Chamber Five Station Washing Device (With provision of hot water in two tank) Drying & Finishing Chambers

jumbo jigger machine

Get Price Quote

Specialized manufacturer, exporter, and supplier of Semi Automatic Maxi Close Type Jumbo Jigger Machine, Stenter Machine, Textile Processing Machinery, Folding Machine for the leading textile industries.The Main wall is made from vibration free M.S. Plate and its connected with M.S. Heavy duty channel.Main 2(two) Nos. Draw Roll will be Manufacturer from Heavy duty M.S. Pipe with S.S. Kliting dia 305mm running in Heavy duty self- aligning ball bearings.Break Drum will be 350mm dia and bush bearing type with best quality of Break Liner and braking arrangement. SPRAY TUBES:- Connected with Supply Pump and placed on both the side of the Trough, Permitting a perfect working of the cloth.Trough will be fabricated from 14 SNG S.S. Guide Rolls with the positioning rolls, Steam coil and sprays with over flow device and a water shut off to a avoid drain system without valve.Differential Gear Box will have M.S. Main Body and ENB gear and Bevel type differential unit. HEATING: Direct or indirect steam coils submerged in the liquor and also we provide Heat Exchanger made from best quality tubes, it is so designed that it heats the dye liquor very fast. BALANCING ROLLERS:- For an optimum processing of some kinds of fabrics, We supply a set of lower able arms to accompany the cloth, With heavy duty S.S. Spring.10 HP AC Electric Motor and AC Inverter Drive, Control Panel and automatic turns and passage with PLC + HMI.Circulating Pump with S.S. Impeller.

jumbo jigger machine

Get Price Quote

Jet Dyeing Machine

Get Price Quote

Jigger Machine

Get Price Quote

We always have following Spares of Jigger Machine readily available from Stock: Brake Drum 10" OD Ratchet & Paul Type complete with, Liner Shoe Locking Spring, Hand Wheel,Cross Bar 17 x 25 x 25 x - pitch for Jumbo Jigger and for 17 x 25 x 25x - pitch for Semi Jigger,SS Tank Roll 304 Quality 14 Ga 70" x 4 - dia with end Shaft 2 -long at both end (shaft dia 35 mm) with mirror polis.

Jigger Machine

Get Price Quote

We mfg. , Supply and Export various type of Jigger, Jumbo Jigger Machine Spares. We have excellent quality range of Brake Drum, Break shoe liner, SS Clading Roll, SS Guide Roll, Sprocket and Bevel gear etcs.

hank yarn dyeing machine

Get Price Quote

Hank Dyeing machine for 54” , 72” and 96” circumference Yarn. For fine counts and coarse counts, for reactive and Vat Dyes – full automation possible. Normally supplied with following standard accessories : 1. Overflow 2. Dye Addition Tank with Pump 3. Spare Set of Sticks 4. Temperature Controller 5. Timer 6. Auto Reverser

dyeing jigger machine

150,000 - 200,000 Per Piece

U TYPE FABRIC DYEING MACHINE

Get Price Quote

We are dedicatedly engaged in manufacturing, Supplying a wide range of dyeing machinery that is manufactured from Top notch material under the supervision of professional expert is widely used in Textile,printing, dyeing, industries,Textile, printing and for huge dyeing business. This machine is well structured and constructed by skilled technicians, experts which include rotary drum washer, fabric long tube machine,fabric loop streamer heavy vessel for high capacity of storing chemicals, separate water tank constructed with different pipes and nozzles constructed from robust and corrosion resistant stainless steel and some parts are from hard aluminum with U Type Fabric Dyeing Machine that produce less foam.U Type Fabric Dyeing Machine stream machine is able to produce equal quality and versatile for dye-fixation on printed fabric for all types of material as natural and synthetic fabric for more color and good functionality is its ability. Also has an automatic sensor for fabric dyeing and loop length can be varied from outside. It is constructed from mixture of quality alloy as alluminium, iron. For heating purpose oil is directly burnt for super heat stream for this low Calorific is required to stream.U Type Fabric Dyeing Machine increase equal streaming time by automatic sensor it gives speed upto 40 to 48 meter/min.Heating different models of 200-265-125-325 meters cloth of single or double width through machines can be passed. FEATURES: Robust design Low power consumption Stainless steel material vessel High capacity storing vessel Dwell time 7 to 10min Easy operating system Produce equal quality With internal stream machine SPECIFICATION: No Weight loss Abrasion resistance No Pilling effects No distortion Complete reel operated Liquor ratio 1:3 to 1:5 Low Power consumption Perfect after service Temperature from130 Deg C to 180 Deg C

Jigger Machine

Get Price Quote

Available Width : 48" To 150" Roller Width Roll Center : 25", 30", 36", 42", 46" Capacity : 225 Kg., 350 Kg., 500 Kg., 750Kg., 1000 Kg. (250 Gsm) Temperature Controller Auto RF System (Optional) Heavy Duty Dyeing Jigger with S.S. Structure S.S. Structure With M.S. Base Frame Inverter Drive Main Roll S.S. Claded Circulation System With 2.0 H.P. Motor & S.S. Vertical Pump

Jigger Machine

Get Price Quote

dyeing jigger machine

Get Price Quote

Best quality material, Stainless ateel winding & unwinding and optimum capacity stainless stell tank with micro processors auto temperature control, A.C Inverter drive, Inverter drive complete with variable running of Mc with auto programmable micro process control, Tension control with break manually operated .

High temperature towel dyeing

Get Price Quote

Technical Details Liquor ratio: approx. 1:8 Capacity per chamber: from 350-500 kg Suitable fabric weight: 600g/m2 or above Heating gradient: 25ºC ~ 100ºC approx. 5ºC/min 100ºC ~ 130ºC approx. 2.5ºC/min (dry saturated steam pressure at 7 bar) Design temperature: 140ºC Design pressure : 3.5 bar Cooling gradient: 130ºC ~ 100ºC approx. 3ºC/min 100ºC ~ 80ºC approx. 2ºC/min (cooling water at 3 bar, 25ºC) Key Features Main control cabinet with FC30 program controller Suitable for high quality towel fabrics Best for dyeing heavy fabrics Machine body and major wetted parts by dye liquor made of 316 Ti/316L Overflow nozzle Heavy duty stainless steel pump, frequency inverter control High efficiency tubular heat exchanger with combined filter compartment Automatic fabric upper tangling release device

glycerin bath beaker dyeing machine

Get Price Quote

With Digital Microprocessor based DP-1 Temperature Controller & Separate Microprocessor based Cyclic Timer for Adjustment of Reverse/Forward Rotation of Rotor. Also gives buzzer after completion of set time.

dyeing jigger machine

250,000 Per Piece

Dyeing Machine Controller

20,000 Per Piece

jigger dyeing machine

450,000 Per Piece

jumbo jigger machine

Get Price Quote

WALL AUTO JIGGER DYEING MACHINE

Get Price Quote

Main tank fabricated from stainless steel sheet, argon welded necessary stiffeners are provided to strength the tank, Drain.Direct and Indirect heating coil is provided for heating tank.Main Roll made from Heavy duty pipe with SS Cladding. Roll Mounted on Heavy duty self bearing & pedestal. The batch rolls are suitable to take fabric up to batch.The Main Wall Structure made from Stainless steel material with MS Channel bottom structure.The Main deferential drive gear box is provided with heavy duty duplex chain and chain wheel cross bar.V' Type ZULHA made from S.S. Solid Shaft.We are provided circulation pump with filter unit with drain valve arrangement (Optional).Electric Control Panel & Remote Box with PLC for Auto forward reverse arrangment in direct with contr

Dyeing Machine

Get Price Quote

Our company is engaged in supplying very useful and efficient Dyeing Machine. The Dyeing Machine provided by us is available in various specifications. Dyeing Machine that we offer is used to dye fabrics like superfine cotton and silk. All the Dyeing Machines are manufactured by us using a whole lot of expertise of our technicians and workers. Why Our Dyeing Machine? Available in automatic and semi-automatic variationsAdjustable liquor flowHigh volume low pressure pumpCustomization facility available on request

Jigger Machine

250,000 Per Piece

Dyeing Textile Machinery

Get Price Quote

jumbo jigger machine

Get Price Quote

Capacity range : 100 Kgs. 500 Kgs. Width range : 48 inch to 120 inch Sturdy frame made of grain cast iron Main rollers made from MS seamless pipe coated with ebonite or S.S. Entire fabric tension controlled by special ratchet brakes