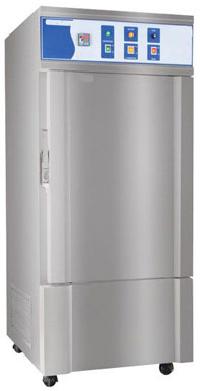

Environmental Test Chamber

Get Price Quote

INTRODUCTION For Environmental Chamber in Ahmedabad, Environmental Chamber in Baroda And Surat “NOVA” Environmental Test Chamber can generate & maintain above ambient temp.,below ambient temp.,and humidity. It is specifically designed for application of various testing under low temp.& with control humidity. APPLICATION: These test chambers are used for climatic and durable Test of electrical & Electronic apparatus, Control penal, Electronic components, Material & components, Chemical Testing, Pharmaceuticals, Geological testing, Conditioning Samples prior to electrical/electronic test as well as TQA Requirement test etc.etc. It can be used as a simulated Tropical & extreme tropical conditions. Nova Instruments For Environmental Chamber in Ahmedabad, Environmental Chamber in Baroda, Environmental Chamber in Surat. SALIENT FEATURES: Fully automatic, temp. control-Micro control Based. Easy to operate. Top Control Penal. Obstruction free working space. Digi. Temp. Indicator & Control (Micro Control) Sensitive Temperature sensor Pt-100 type. Floor model. Castor wheel for easy move ability. Elegant outlook, enamel painted/powder coated. Glass door/window to see through. Forced air circulation. Humidity Control by dry & wet principal. Digital Humidity Indication (Optional). Stainless Steel steam boiler. Panel Meters- Volt & Ampere. Suitable for climatic & durable tests. Auto Water level CONSTRUCTION: The unit is of double walled construction. The exterior chamber is made of mild steel and finished in non corrosive paint or powder coated and interior chamber is made of heavy gauge polished stainless steel. Between two chamber glass-wool /  thermocole  insulation is provided. Glass window/Door is provided to see the operation without disturbing the control condition inside the chamber. An outside metal door with lock is provided. The unit rest on castor wheel. HEATING: [A] Chamber is heated by long lasting air heater to eliminate failure of heater.[B] Boiler heater is of immersion type heater. COOLING: Using hermetically sealed compressor coupled with evaporation coil & fan cooled condenser. HUMIDITY : Humidity generated by steam injection near the duck from a boiler connected to water tank fitted with water level controller. Humidity set & derived by dry & wet bulb principles by the provided depression chart. INDICATION & CONTROL : Digital display indication for temperatures. Fully automatic solid state electronic controllers with Pt-100 sensors for both dry & wet bulb controllers are panel type easy for maintenance/service. CONTROL PANEL: Control panel is provided on the top of the unit consisting of Mains switch, Mains indicator, Ampere meter, Voltmeter, Wet bulb Digital Indicator cum Controller, Wet bulb Indication pilot lamp, Dry bulb Digital Indicator cum Controller, Dry bulb indication pilot lamp (For cooling cycle-heating cycles), Low water level controller fitted and connected through circuit to boiler heater low level pilot lamp (will not glow if water level is below requirements), Door heater switch (Optional), Chamber light switch (Optional).

FREEZE THAW CHAMBER

Get Price Quote

Best Deals from Environmental Test Chambers

Environmental Test Chamber

Get Price Quote

EIE-105 NON-REFRIGERATED MODEL EIE-106 WITH REFRIGERATION SYSTEM FOR STABILITY STUDIES EIE-105 Non-Refrigrated Model Double walled, inside chamber stainless steel, outer body made of CRC/G.I. - powder coated, Temp. Range from ambient +5° C to 60° C controlled by Dual Display Microprocessor based Digital Temp. Controller with +/- 0.5° accuracy, Humidity range from atmospheric humidity to 95 % controlled by Dual display Microprocessor based Digital Temp. Controller (Dry and Wet bulb method) with + 3 % RH. Inner water tank made of stainless steel with ball cock valve. Front door has a full view glass observation window. Optional Fittings for EIE - 105 Microprocessor based direct RH digital controller in place of Digital Temp. controller. Hygrometer(0 - 100%) EIE-106 With Refrigeration System: With Refrigeration System. Double walled, inside chamber stainless steel, outer body made of CRC/G.I. - powder coated, Temp. Range from 10° C to 60° C controlled by Dual display microprocessor based Digital temp. indicator cum controller with ± 0.5° C accuracy or better. Cooling system consist of high efficiency Kirloskar Make compressor with relevant accessories. Humidity range from atmospheric humidity to 95 % controlled by Dual display Microprocessor based Digital Temp. Controller (Dry and Wet bulb method) with accuracy + 3 % RH or better. Inner water tank made of stainless steel with ball cock valve. Front door has a full view glass observation window Optional Fittings at Extra Cost Illumination by 2 nos. fluorescent tubes. Digital Environmental controller (Direct % RH Type) Temp. range (dry) 5 to 60°C. Humidity range upto 95% OR Digital controller (Direct % RH Type) Temp. range (dry) above ambient to 60°C. Humidity range upto 95% with Printer interface to connect any dot matrix line printer. Features : Microprocessor based, programmable - date, time, humidity/temp., print interval. Data memory storage capable of storing data upto 30 days. High/Low deviation alarms, low water level electronic cut-off with visual alarm. Shared printing compatibility with other Humidity Ovens. Computer Software (HControl) provided Digital Controller with printer interface installed to monitor from computer in remote location. Single software for three Humidity Oven.(however, cabling shall be charged extra) 4 Point Temp. + 4 point Humidity data logger with sensors placed at specific points in chamber with printer interface and memory. Voltage Stabilizer for above 6 KVA The above Humidity Oven can be converted into PLANT GROWTH CHAMBER by using 4 fluorescent tube light provided with 24 hours ON/OFF programmable timer for Day /Night effect. Temp. range 15° to 60° C. At extra cost. Optional Accessories(at extra cost) Double wall construction interior fabricated of stainless steel(S.S.304). Exterior of corrosion resistant galvanized sheet, finished in powder coated epoxy paint. Full size glass inner door to inspect samples without affecting the chamber temp. outer double walled metal door with magnetic gasket and lock. Unit mounted on castor wheels for easy movement.70mm polyurethane insulation (PUF) to ensure better insulation and less leakage of temperature or 10% RH from inner body to the surroundings. Air Circulation Temperature is maintained by a quiet running blower circulation air through out the chamber. Forced air circulated vertically down and re circulated through out the chamber for uniform temperature and humidity. Humidity Humidity created by steam injection method. The boiler tank is fitted in the back side of the chamber for better servicing, Electro magnetic switch for controlling the wet heater from burning off if water level is not adequate. Float valve provided to control water level in the boiler tank. Heating & Cooling System Long lasting SS tubular heaters used as heating element. The stainless steel tins provided to ensure better heat transfer. Hermetically sealed compressor CFC free compressor (134 A gas) coupled with evaporation coil and condensor. Trays Removable perforated trays provided made of S.S. Control Microprocessor based temp and direct RH digital PID controller. Humidity directly measured in % RH by electronic sensor. Temp. Range 10 to 70°C, Accuracy +/- 0.5°C Humidity Range 40% RH to 90% RH Accuracy +/- 3% RH ICH Guidelines As per ICH Guide lines, stability studies to be carried out under the following conditions. Long Term At 25°C (+/- 2°C) & 60% RH (+/- 5% RH) Validation ; Validation of the chamber (Heat Mapping) will be done at 8 zones in the chamber using 8 channel scanner (4 works and printout of the result will be provided. For on site validation charges extra. Optional Fittings at Extra Cost: Digital Controller with Printer Interface to connect EPSON dot matrix line printer. Print Interval programmable, can print date, time, temp. and humidity. Do- but with standard PC software and connectivity. * 21 CFR Part 11 Comliance Software Datalogger : 4 point temp. + 4 point humidity datalogger with sensors placed at specific points in chamber with printer interface and memory of 5000 readings per channel. * 21 CFR Part 11 Comliance Software Additional high temperature safety system to cut-off all heaters with audio-visual alarm ensuring temp. within chamber doesn't exceed +70°C Voltage Stabiliser for above unit. EPSON dot matrix 80 column Printer with stand. Standby Humidity and Refrigeration system. 10 Ltr. capacity aspirator bottle(PP) for storage of Mineral water and to serve as input water source for the Water tank/ Steam boiler of Oven i. Silicon rubber tubing - 3 meter for water supply from reservoir to Boiler (Option h and i are compulsory - either customer should have his own arrangement or should be ordered alongwith the Humidity Oven) Pre Installation Mandatory Requirement (Guarantee void incase of non compliance) Distilled water OR DM water continous supply with tap for boiler input of 1/2" BSP at 3 feet height. Room temperature around machine preferably @ 25`C. with air conditioning or a well ventilated room with exhaust fan. However, surrounding temperature should not exceed 30 Deg.C. Stabilized Input Voltage of 230V AC 20 Amps. Use of Servo Controlled Stabilizer is recommended. Water drain line with 1/2" nozzle to be provided at floor level.

Environmental Chamber

Get Price Quote

Environmental Chamber, tensile testing equipment, Digital High Voltage Tester