Evaporator Tube Cleaning System

Get Price Quote

1 Set (MOQ)

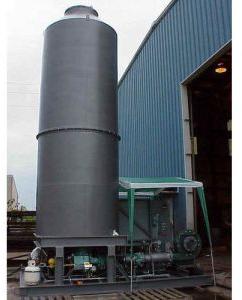

caustic recovery plant

Get Price Quote

In such grim situation one has to really start thinking a fresh on various profit making avenues which were being ignored in better times. The ideal way of looking at it is basically looking at points to save wastages of various resources and recover it profitably wherever possible.Details :Braj Projects Pvt.Ltd. has a team who have an experience of More then 10 Years in recovery from waste offering various projects such as heat recovery systems ,salt recovery and caustic recovery system / caustic recovery plantExplanation :Mercerisers for Textile Mills generate dilute caustic liquor, which if drained to effluent treatment plant, will create considerable problems in meeting the environmental standards. Caustic recovery system / caustic soda recovery plant by concentrating wash liquor and using the same back in Merceriser is the only feasible solution.Principle :Under caustic recovery system / caustic soda recovery , Caustic at low concentration is heated to its boiling point with the help of a heat source and the vapors generated due to boiling are used to heat the weak liquor. This hot liquid is then flashed at lower pressure and the vapors so generated used again. The weak liquor is concentrated to 250-300 GPL as in case of dry Merceriser or 450-500 GPL in case of wet Merceriser which can be reused with a minor topping up of caustic.Operation : Weak Caustic lye, around 5-6 Be ( 40 - 50 gpl ), is collected from the impregnation and washing chamber into a storage tank. It is then taken to a filtration unit to filter the suspended solids, fluff etc. The feed to CRP then passes through a series of preheaters which preheat the wash liquor with the help of flash vapors from the condensate flashes ensuring minimum steam loss in heating the Wash liquor to its boiling point.The liquor in the tubes comes in contact with the steam in the shell side of heater 1 and the liquor starts boiling. The vapor liquor mixture enters the flash vessel through a tangential entry and the vapors get separated and enter the shell of the 2nd stage. The boiling in the successive effect takes place due to lower pressure created with help of a water ring vacuum pump. Due to lower pressure the boiling point of the liquor is reduced and it starts boiling. The concentrated liquor enters the 2nd heater due to the pressure difference and comes in indirect contact with the generated vapors and the same procedure is repeated. The concentrated product is removed from the last stage by a product pump.This later is taken either to a storage tank or to a Concentrated Lye purification system . Under caustic recovery system / caustic soda recovery plant vapors generated at the last stage need to be condensed. This is done by either HotWateror an Adiabitc Evaporatorsystem. In case of a hot water system, water at room temperature is passed through tubes of an exchanger and it gets hot due to the vapors. This hot water is uncontaminated and hence can safely be used in the process or the boiler as per the requirement. In some cases where the hot water generated cannot be effectively consumed the effluent is passed through the exchanger and sprayed in an Adiabatic Evaporator Here the waste heat is lost in form of vapors and hence effective steam consumption of steam is reduced. Also nuisance of excess hot water is eliminated.

Best Deals from Evaporator

Multi Effective Evaporator

Get Price Quote

Uni-Mech Multi Effect Evaporators are the equipment in which steam from an outside source is condensed in the heating element of first effect. The boiling temperature at which the first effect operates is high enough so that the evaporated water can serve as the heating medium for second effect. The vapors so formed are then sent to a condenser if it is a double effect evaporator. The feed for the multi-effect type evaporator is generally transferred from one effect to another. This leads to the ultimate product concentration to reach the desired effect through the evaporator. Uni-Mech offers many Evaporators like : Falling Film Evaporator Thin Film Evaporator Forced Circulation Evaporator Rising Film Evaporator

Evaporator

Get Price Quote

An evaporator is a equipment used to vapourise water part from the solution / material thru heating process.

Industrial Evaporators

300,000 - 2,000,000 Per Set

1 Set (MOQ)

effluent evaporators

25,000 Per Unit

1 Unit (MOQ)

Rotary Vacuum Evaporator

Get Price Quote

To ensure distribution of orders within undertook period, our organization has an outstanding supply chain system in place. Situated in Ahmedabad(India), the company has carved a niche for itself in the market with its flawless range of products. The avant-grade rotary vacuum evaporator we offer rotates with a speed of 160rpm.

Waste Water Evaporator System

Get Price Quote

We make available Waste Water Evaporator System which is reckoned for its make and long service life. Our company packs the entire range of products with superior-grade packaging material that is nontoxic and recyclable. Furthermore, the packaging prevents damage and ensures the product is kept safe. Our company is ranked amidst progressive distributors of the product in Ahmedabad(India) as well as varied other marketplaces.

forced circulation evaporator

Get Price Quote

Circulation evaporators are a type of evaporating unit designed to separate mixtures unable to be evaporated by a conventional evaporating unit. Circulation evaporation incorporates the use of both heat exchangers and flash separation units in conjunction with circulation of the solvent in order to remove liquid mixtures without conventional boiling. These type of evaporators some mechanical device are fitted to circulate the contents heating in it. For example an evaporating pan in which the materials is agitated by a stirring rod or by a mechanical propeller. The liquid is circulated by means of a pump and as it is under pressure in the tubes the boiling point is raised and no boling take places. And it enters the body of the evaporator.

Waste Water Evaporator

100,000 - 2,500,000 Per Piece

1 Piece (MOQ)

A wastewater evaporator is a device that uses heat to evaporate water from industrial or municipal wastewater, leaving behind a concentrated waste stream that can be disposed of more easily and cost-effectively. The process involves boiling the wastewater in a vessel, where the water evaporates, leaving behind a concentrated residue or sludge.

STEAM BTAH UNIT EQUIPMENTS

32,600 - 97,000 Per piece

1 Piece (MOQ)

Solar Waste Water Evaporator System

Get Price Quote

The Waste water will be pumped on a Metal Open tray (painted with absorber paint) through a simple pump and from there it will be falling on the Receiver by gravity. The receivers will be heated by concentrating solar energy. The temperatures on the Receivers will be more than 1,000° C. The falling water on the receivers will start evaporating and the rest of the water which is not evaporated will be heated up. The heated water will fall again in the nearby Solar Pond through a sprinkler system and the cycle will be repeated continuously. To control the flow of water, we will be installing level indicator with a controller to make the process completely automatic. TSS reserves the rights for any improvements in the above specifications, which can lead to higher efficiency and cost reduction of the system.

Rotary Vacuum Evaporator

Get Price Quote

10 Piece(s) (MOQ)

We are offering rotary vacuum evaporator. description • low profile design gives ease in operation. • spark less drive unit ac motor with assured speed regulation- 50 to 250rpm. • digital temperature controller for water bath. • ptfeglass sealing mechanism. • smooth, adjustable, maintenance free single lever manual lift. technical data rotational speed 50-250 rpm heating bath dimensions 230 x 130 mm. Volume of heating bath 4 litre approximate bath temperature range ambient to 180o heating bath controller pid with display set & actual temperature heating bath material ss 304 minimummaximum flask size 50ml3000ml lift mechanical height adjustable 170 mm. Approximate flask ejector yes condenser support yes power supply 230v ac, 50 hz model no product description s.s.101 rotary vacuum evaporator with digital water bath s.s.102 rotary vacuum evaporator with analogue water bath

MIST EVAPORATOR UNIT

150,000 Per Set

1 Piece (MOQ)

Multi Effect Evaporator Plant

1,500,000 - 5,000,000 Per Piece

1 Number (MOQ)

evaporation plants

2,500,000 Per Plant

1 Plant (MOQ)

wiped film evaporator

Get Price Quote

We have parted our infrastructure into different units and one of them is warehouse wherein we keep our product lot for meeting urgent and bulk requirements of the buyers at a time. Our organization is graded among receptive and responsible Suppliers of Wiped Film Evaporator, involved in providing to purchasers across diverse marketplaces.

forced circulation evaporator

Get Price Quote

Mazda Forced Circulation Evaporators are recommended for the concentration of high viscocity solutionsslurries having tendency to crystallize or produce scales.Advantages:Ideal for high crystallizing and high viscosity solutions & slurries,High operational flexibility, heat transfer co-effecients, vapour liquid separation.

Electric Evaporator

Get Price Quote

Solution to Zero Liquid Discharge One of the technology that is based on the process of complete elimination of all liquid discharge from a system. The goal is to reduce the volume of waste water that requires further treatment. It's advantages are as follows: Well designed and aesthetically very good. Completely automatic with microprocessor control. Continuous operation with minimum operating assistance. Solid Waste volumes for disposal to TSDF can be reduced significantly. Highly Energy efficient Easy to install Easy to operate Suitable for numerous applications to achieve ZLD.

Evaporators

Get Price Quote

We are leading manufacturer, supplier and service provider of Evaporators in India, which is fabricated as per ASME/IS/ ASTM standard.It has various ranges in capacity. This is use in chemical industries, Dairies, etc.