0-500 kg/hr Fluidized Bed Combustion Boiler

1,000,000 Per Piece

1 Piece (MOQ)

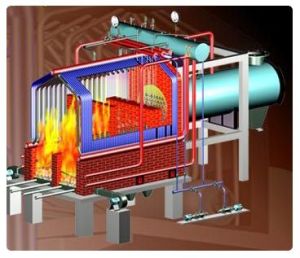

Fluidized Bed Combustion Boilers

1,000,000 - 20,000,000 Per Piece

1 set (MOQ)

We are engaged in the manufacture, export and supply of Fluidized Bed Combustion Boilers. We use only finest quality material to manufacture these boilers. Our Fluidized Bed Combustion Boilers are preferred for their efficient & trouble free performance. In these boilers, the fuel is burnt in suspension of hot bed material consisting of sand, ash and additives.

Best Deals from FBC Boiler

fbc membrane water wall steam boilers

Get Price Quote

1000 Kilogram (MOQ)

boiler is mainly cost as per the capacity in kgs /hr and weight 250rs /kg ibr

Water Tube FBC Steam Boiler

Get Price Quote

4 Pass design, ensures better heat utilisation & ultimate thermal efficiency. Fluidised Bed Combustion furnace ensures very high combustion efficiency, up to 95% even with fuel, having very high ash & fine contents and having very low calorific value. Straight tube in generating bank enables manual cleaning & easy inspection. The rectangular headers are of welded type box headers with individual opening against each tube at both ends of generating bank. Hence, for cleaning & maintenance of any single tube only single door cap, weighing just 1.5 kg has to be opened. Larger tube diameter in generating bank, i.e. 76.2 mm OD, enables easy manual cleaning. Intermediate tube supports in the generating bank, which prevents tube sagging contributes to higher boiler life. Wide gap in tube spacing i e. 160 mm pitch, prevents inter tube space plugging by soot deposition, which permits trouble free operation without external cleaning as clogging of tube space with soot does not take place. Free floating front header takes care of longitudinal thermal expansion. Hence, thermal stresses are not developed during heating. This design enhances boiler life too. Man hole opening at both sides of the drum for easier access to drum internals. Larger diameter drum coupled with drum internal steam separators ensures dry steam even at full main steam valve opening. Moderately larger furnace area and higher free board height, above grate, makes the boiler capable to burn low grade, high volatill3 & ash contained solid fuel efficiently without reducing rated steam generating capacity. No inventory of spares, since nothing special is employed which is necessary to be procured urgently from us or which is not available in the free market.

Water Tube Drum Fbc Boiler

Get Price Quote

STEAMPOWER is a two-drum water tube boiler from BALKRISHNA. STEAMPOWER can be used to combust a wide variety of fuels.STEAMPOWER is most suited for applications that require uninterrupted boiler operation even on fuel which have a high fouling tendency. STEAMPOWER can be used for generating saturated steam as well as superheated steam. Superheated steam is used for incidental power generation or cogeneration power in industries such as distilleries, paper, solvent extraction, rice, textiles, etc.STEAMPOWER is available in different combustion systems depending on the fuel. FBC is suitable for burning coal or lignite or other agro-based low-grade fuels Dumping grate or pulsating grate is suited for burning fibrous & moist fuels obtained from industrial waste & agricultural residues Travelling grate is suited for burning low ash fuels

fbc boiler

Get Price Quote

Built-in Super heater, Choice of Fuel Feeding Systems - In Bed for Coal, Lignite, Saw Dust. - Over Bed for Rice Husk. Bio Gas Compatible, Microprocessor Controlled Fuel Feeder Water cooled, Suvega Tube Water wall. Packaged Concept, Minimum welding at Installation site. No Expansion of tubes

fbc steam boiler

Get Price Quote

fbc steam boiler, fuel fired steam boiler, Oil Fired Boiler

FBC Boilers

Get Price Quote

FBC Boilers, Biogas Fired Boilers, Agro Waste Fired Steam Boiler