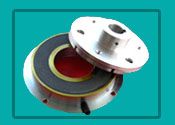

Flange Mounted Brake

Get Price Quote

TYPICAL APPLICATIONS : Textile Machines, Printing Machines, Machine Tools, Pick & Place Robots, Plastic Machinery, Conveyors, Laundry Machines, Brake Motors, Paper Machines, Bottle Washing Machines, Wire Drawing Machines, Coil Winding Machines, Packaging Machines... etc. COMPONENT DESCRIPTION : 1. Stator2. Coil3. Friction Lining4. Armature Plate5. Leaf Spring6. Flanged HubWORKING These type of brakes are normally-off type and operates on power. When power is given to the stator (coil), the armature is attracted towards the asbestos free friction liner of the brake stator which clamps the rotating component stop at once.On switching off the electric power, the unique prestressed spring pulls the armature plate back into its original position and brake positively released with no residual torque. WORKINGThese type of brakes are normally-off type and operates on power. When power is given to the stator (coil), the armature is attracted towards the asbestos free friction liner of the brake stator which clamps the rotating component stop at once.On switching off the electric power, the unique prestressed spring pulls the armature plate back into its original position and brake positively released with no residual torque. SWITCHINGNormally off type clutches operate on D.C. voltage, hence A.C. to D.C. conversion is done by means of a suitable rectifier.Switching of the brake can be on either side. However, once application demands, higher switching frequency / faster engagement and disengagement time, switching must be carried out on D.C. side. To restrict the high inductive voltage / back EMF a suitable supressor and capacitor network is provided across the contactor coil.