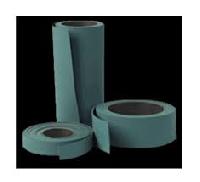

TURCITE EQUIVALENT MATERIAL

We are offering turcite equivalent material. Quite simply turcite is ptfe impregnated with fillers and additives that serve to enhance the wear properties of the material. It is used, most often in a sheet form, in thicknesses ranging from 0.5mm (0.02) to 4mm (0.16), although in some applications, it is also used as a bush and in more rare applications it is used as a thick plate.

...more

TURCITE EQUIVALENT

Quite simply – Turcite ® is PTFE impregnated with fillers and additives that serve to enhance the wear properties of the material. It is used, most often in a sheet form, in thicknesses ranging from 0.5mm (0.02”) to 4mm (0.16”), although in some applications, it is also used as a bush and in more rare applications it is used as a thick plate. Being based on PTFE, the material cannot be extruded like a normal plastic sheet and instead needs to be “skived” – the process most commonly used to make thin PTFE sheets. Also, the material will not easily adhere to other surfaces – another feature resulting from its PTFE base. Therefore a chemical etching is required on one surface of the material, so the sheet can be bonded to other articles. APPLICATIONS. Planers, milling machines SPMs Sharper's, horizontal & vertical boring machines, hydraulic & pneumatic power presses, press brakes, all types of grinders, radial drills, automatic screw machines, gear hobbers, gear shapers.

...more

SPRING ENERINGSED SEAL

Spring Energised seals are single acting seals which are used for dynamic and static applications.They are effective in a wide range of applications. They are chosen when higher resistance to chemical media is required, if the seal is required to operate in extremes of temperature and where good extrusion and compression characteristics are needed. Spring Energised Seals have three main design characteristics: 1. Application specific U-shaped seal profile2. Spring geometry suited to the particular application3. Proven high-performance polymers Standard products are available from 2 mm up to 2500 mm (8' 2") in diameter along with custom Manufactured intermediate sizes, inch (imperial) sizes or special geometries. Method of Operation All seals have the same operating principle and differ only in their profile form and type of metallic spring used. The spring supplies the load required for sealing at low pressures. The "U" shaped jacket allows fluid pressure to energize the sealing lips, so total sealing pressure rises with increasing operating pressure Spring Force. Performance: The different types of seal combined with the properties of materials offer design engineers a wide range of solutions to a large number of applications. The most important characteristics of Spring Energised Seals are listed below:Very low coefficient of frictionGood dynamic and static sealingCapable of sealing at high speeds up to 15 m/s (49 ft/sec)Almost universal chemical compatibilityOperating temperature of -253 °C up to +300 °C (423 °F to 572 °F)Very good thermal resistancePermanent elasticity unaffected by contact with chemicalsGood ageing characteristicsLow compression setCapable of withstanding high pressures above 200Mpa (2000 bar, 29000 psi) when using Back-up RingsVery good dry-running properties Choosing the right seal for your application: Spring Energised seals offer major benefits in the design of components such as hydraulic and pneumatic cylinders, in all industries.These include:Excellent leak tightnessHigh resistance to wearNo extrusion into gapsWithstanding aggressive and abrasive process mediaVery good temperature capabilitiesLow frictionCompact formSimple installation These seals are available in a range of geometries and designs that allow the optimum profile to be selected for each application. They can be produced from a wide range of PTFE based compounds. These are specially formulated for sealing elements and offer superior characteristics specifically matched to the demands of our customers. When required, Spring Energised seals can also be manufactured in polyethylene based material. To choose the best seal for your application, you must first decide the functional parameters. It is also important to consider the quality of the mating surface, which has a significant effect on the function and service life of the sealing system. Advantages : 1 - Could be provided by kilogram or meter 2 - High abrasion resistance, wide range of application temperatures 3 - Low friction, high efficiency 4 - Stick-slip free starting, no sticking 5 - Easy installation

...more

PTFE Sleeves

PTFE Insulated Sleeve application is for high temperature or high frequencies or both. PTFE Sleeve and teflon sleeve possesses excellent electrical properties, which remain practically constant over a wide range of frequencies, temperature (-600 to +2600 C) and humidities and has a very low loss factor. Advantages : Resistance to fire Resistance to Chemicals Corona resistance Non-flammable

...more

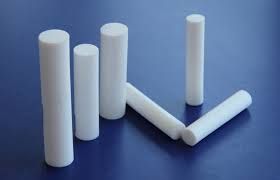

Ptfe Rods

We are offering ptfe rods. Ptfe rod is often chosen to produce bearings because of its very low friction and also for its free running ability. Because of its ability to conform to shape otherwise known as flow, ptfe rod is used for seals in valves, this is because it can conform to shape and create a high specification valve seal.

...more

PTFE ROD AND TUBES IN CONTINUOUS LENGTH

PTFE Rod is often chosen to produce bearings because of its very low friction and also for its free running ability. Because of its ability to conform to shape otherwise known as flow, PTFE Rod is used for seals in valves, this is because it can conform to shape and create a high specification valve seal. PTFE Rod can easily be machined but due to the surface softness, care must be taken in lathe jaws or high compressive loads, which may cause distortion Another important element to remember regarding PTFE Rod is the coefficient of expansion due to heat changes; this can be uneven with PTFE and may cause distortion in components. PTFE Rod is manufactured in two distinct ways, extruded PTFE Rod is the most popular and is relevant to smaller sizes, Molded PTFE Rod is relevant to the diameters over 100mm in size, smaller sizes are also available in extruded form. Size : PTFE Rod is often made in diameters ranging from 3mm diameter up to a maximum diameter of 300mm diameter and is made in lengths which range from 100mm to 1000mm

...more

PTFE Ring

We are one of the leading manufacturers of a wide range of PTFE Ring Gasket. Our range of PTFE ring and gasket is manufactured using molding method with PTEF method with PTEF granular resin. PTFE, compared with other plastics, has superior properties against chemicals and temperature. The PTFE ring & gasket offered by us is highly admired by all our clients due to their high reliability as well as durability. These ring joint gaskets are especially designed to withstand exceptionally high assembly loads over a small area, thus producing high seating stresses.

...more

PTFE PISTON SEAL AND ROD SEAL

Produced with a combination of special compound PTFE ring and 70 shore NBR O-ring, our BSJ design has a wide application area. Being able to be usded safely at high linear velocity,BSJ type seals can also work in higher temperatures or different liquids by means of changing o-ring used as pressure ring. By the help of its profile design they can be used as header pressure ring in hydaulic systems without having the problem of hydro-dynamic pressure. Material: Material: Almost all media O-ring: NBR/FKM Color: Green/Brown O-ring: Black/Brown Advantages: High static and dynamic sealing effect Low friction, high efficiencyStick-slip free starting, no sticking Easy installation

...more

Ptfe O Ring

Still have questions about finding a standard or non-standard o-ring size? Feel free to either contact us with your questions or use our online o-ring size search. Easy to Order, Fastest Delivery When you are ready to get started, submit an online RFQ to receive a quote from our dedicated sales team within 24 hours. Most likely the size and compound you require is in our inventory of over 300 Million o-rings. You receive immediate shipments with no intermediate delays. Remember: With Apple Rubber, you buy direct. Standard O-Ring Material Applications We offer the following six (6) standard rubber materials in a range of durometer (Shore A) hardnesses to satisfy practically any service condition: Viton® / FKM: Fluorocarbon (Viton®) exhibits exceptional resistance to chemicals, oils, temperature extremes (-13°F to +446°F), low compression set, low gas permeability and excellent aging characteristics. Applications include: aircraft engines, automotive fuel handling systems, and chemical processing industries. FKM is also suitable for high vacuum applications. It is not recommended for exposure to ketones, alkalis, and Skydrol®fluids Custom compounds are available with improved chemical and low temperature resistance. Nitrile / NBR: Nitrile (Buna-N) is the most widely used elastomer due to its excellent resistance to petroleum products, operating temperature range (-40°F to +257°F) and one of the best performance-to-cost values. It's an ideal material for aerospace, automotive, propane and natural gas applications. Special Hydrogenated Nitrile (HNBR) compounds can improve resistance to direct ozone, sunlight, and weather exposure while increasing temperature range to +300°F. Ethylene-Propylene / EPDM: EPDM has outstanding resistance to heat, water and steam, alkali, mild acidic and oxygenated solvents, ozone, and sunlight (-40ºF to +275ºF); but it is not recommended for gasoline, petroleum oil and grease, and hydrocarbon environments. This popular rubber compound is usually the first choice for low torque drive belt applications. Fluorosilicone / FVMQ: Fluorosilicone (-75º to +400ºF) combines the good high and low temperature stability of silicones with the fuel, oil, and solvent resistance of fluorocarbons. FVMQ is unparalleled for aerospace fuel systems, auto fuel emission control systems and to meet or exceed government, military, aerospace, automotive, industrial and commercial specifications. However, due to relatively low tear strength, high friction and limited abrasion resistance of these materials, they are generally not used in dynamic applications. They are also not recommended for exposure to brake fluids, hydrazine, or ketones. Silicone / VMQ: In the Silicone family, you will find compounds which are superior as static seals in extreme temperature conditions. Standard compounds handle operating temperatures -85º to +400ºF. Silicone compounds are popular in food and medical applications because they are very clean and do not impart odor or taste. Special Phenyl silicones can be used down to -148°F. Neoprene® / CR: Neoprene (-40º to +250ºF) is reasonably priced and features good resistance to petroleum oils, ozone, sunlight and oxygen aging, relatively low compression set, good resilience and outstanding physical toughness. It is the preferred sealing material for the refrigeration industry because of its resistance to ammonia and Freon®. Let us know if you require materials to meet the following standards; UL, MIL, AMS, ASTM, FDA 21 CFR 177.2600, USP Class VI, or ISO 10993. We have many special compounds that can meet the specification you are looking for. Need help choosing an o-ring material? Try our new, Interactive Material Selection Guide. For assistance with o-ring size or material selection, contact us today.

...more

PTFE LIP SEAL

The widest product range in the sector Due to their elastomer sealing lip, standard radial shaft seals have only a limited application range with respect to pressure , temperature and media loads.High performans sealing lips made from modified PTFE , cause very low friction , thanks to their stick-slip-free running , suffer little wear and tear, reducing the heat development and permitting higher peripheral speeds. Advantages of PTFE seals are : 1 - Low friction seal material2 - Low and high temperature range (-60 to +260 ºC3 - High pressure capability (up to 25 bar )4 - High speed ability ( 40 m/s )5 - Outstanding resistance to chemical media6 - Fits Standard oil seal installation groove. Given the many different needs involved in practical applications, TOKEZ offers users many different product versions , ranging from standard one lip , ready to-install , available from stock; right through to customized special designs. Materials: Sealing Lip 1 - Standard material with exceptional wear and friction characteristics.For lubricated or dry running. Carbon filled , Black colour.2 - Special material for all lubricating and non-lubricating fluids and suitable for soft counter-surfaces. Moly filled , Grey colour.3 - Special application such as food stuff , pharmaceutical and chemical industries. Colour : Tan to dark brown. Case Material : Gasket Elastomer Standard material : Fluoroelastomer (-25 to +200 C) Typical applications: 1 - Centrifuge machinery2 - Pumps3 - Mixers4 - Separators5 - Agitators6 - Spiral conveyors.7 - Rotary lead-throughs

...more

PTFE GUIDE STRIP

Guide strip/ring have an important place in hydraulic and pneumatic systems. If there are radial loads in the ysytem and no protections are provided, sealing elements do not function and also there may be permanent damage for the cylinder. BST guide strip are produced with PTFE filled with 40% Bronze, standard smooth surface or structuralization coining surface for options. Our BST guide strip could be priced and provided by kilogram or by meter. Material Material: PTFE filled with 40% Bronze Color: Green/Brown Advantages Could be provided by kilogram or meter High abrasion resistance, wide range of application temperatures Low friction, high efficiency Stick-slip free starting, no sticking Easy installation

...more

PTFE Gasket

gasket are available in 1.5 mm, 2 mm & 3 mm, 4 mm, 5 mm thick. Gaskets are manufactured to suite different flange standard like; E/F table, ANSIB-16.5-150, 300 & 600. Class flange, “DIN” standard flanges from 1/2” NB (15NB) to 28” NB. PTFE gaskets are available in raise face size & full face size. PTFE gaskets are also available as per client drawing specification.

...more

PTFE FILLED PTFE MOULD

We are offering mould ptfe also famous as ptfe stock shapes. We can provide ptfe mouldsmoulding raning from 10mm id to 1000mm od. We can provide ptfe mouldsmoulding ranging from upto 300mm height.

...more

PTFE FILLED PTFE MOULD/STOCK SHAPES

MOULD PTFE ALSO FAMOUS AS PTFE STOCK SHAPES. WE CAN PROVIDE PTFE MOULDS/MOULDING RANING FROM 10MM ID TO 1000MM OD. WE CAN PROVIDE PTFE MOULDS/MOULDING RANGING FROM UPTO 300MM HEIGHT. MATERIALS WHICH WE CAN SERVE ARE AS PER BELOW VIRGIN PTFE VIGIN PTFE (MODIFIED) 15% GLASS FIELD PTFE 25% GLASS FIELD PTFE 25% CARBON FIELD PTFE 35% CARBON FIELD PTFE 40% BRONZE FIELD PTFE 60% BRONZE FIELD PTFE 55% BRONZE + 5% MOLY. FIELD PTFE MANY GRADES EQUIVALENT TO ROLON. GRADES EQUIVALENT TO TURCITE, TURCON ETC.

...more

Ptfe Envelope Gasket

It excels at sealing irregular surfaces and maintaining a tight seal under demanding processing and system conditions. Typical applications This material is recommended for gaskets used in flange sealing duties in steel pipes and equipment for pharmaceutical, food and beverage processing. Prime features : Suitable for pharmaceutical, food and beverage processing duties.Resistant to creep and cold flow.Maintains a reliable, durable seal.Dimensionally stable.Conforms easily - seals irregular flanges.Retains tightness - minimum re-torque.Documented lot traceability. Specifications : USP Class Vl Biocompatibility.US food contact compliance: FDA 21 CFR 174.5(d).EU food contact compliance: Chemical properties : Resistant to all media in the range pH 0-14, excluding alkali metals and elemental fluorine, particularly at elevated temperatures. Notes: Temperature stability: expanded PTFE is stable in temperature ranges typically found in food and pharmaceutical applications: -100°C to +270°C with excursions to +315°C (-148°F to +518°F with excursions to +600°F). How supplied: Standard thicknesses: 1.5mm & 3.0mm. Standard sheet size: 1524mm x 1524mm.

...more

PTFE Bellows

Bellows are specially designed from virgin PTFE and is contour molded. This manufacturing method guarantees an excellent structure of the material; symptoms of ageing are practically excluded. Very long term durability and low maintenance cost are assured. The bellows can be used up to 200oC. Bellows serve for compensation of vibration, thermal strain expansion and Axial & Redial motion. The sealing surfaces are covered end plates and individually boxed for protection against mechanical damage. Limit bolts are preset to prevent over extension during operation. These Bellows are meant for resisting highly corrosive plants and piping for aggressive Medias. These Bellows are installed in PTFE Lined Carbon Steel Piping and equipment without additional gaskets. For use with piping and equipment made of glass, enamels and ceramics we recommend PTFE Gaskets, offered as accessory. Size : Bellows are manufacturing in different sizes from NB 25mm to NB 300mm. The standard length is 67.5mm long.

...more

PTFE Balls

Our PTFE Balls are perfectly used, where metals or alloys cannot be used. PTFE Plastic Balls are highly functional in self-lubrication conditions such as ball bearings. Today, we are counted among the key PTFE Balls Manufacturers and Suppliers in India. Solid PTFE Balls are available in size range of 6mm to 10mm or according to the specifications of our customers. Description : The PTFE ball is a unique product. It has many advantages in applications where metals or alloys can not be used. These advantages are Broad operating temperature (-400oF to +500oF), Chemical inertness to most corrosive liquids or gases extremely low coefficient of friction. PTFE balls are highly functional in self lubricating conditions such as ball bearings. In the fluid handling industry PTFE balls are used in ball valves that have contact with extremely corrosive liquids. PTFE ball has reduced maintenance costs and man hours in the field by eliminating the replacement of valve components subjected to corrosive environments. Size : Balls are available in size from 6mm to 150mm. But it can also be made in any specifications.

...more

PTFE Ball Valve Seat

We are among the leading manufacturers, suppliers and exporters of wide range of high quality PTFE Ball Valve Seats. These products undergo various quality assurance procedures at each level of their productions, to ensure high standards of quality and safety. These products are chemically inert to attack by most chemicals. These products are available in standard sizes that best suits the requirement of our valuable customers. These products are available in various grades for our valuable customers. We believe in effective and timely delivery of these products once ordered, owing to vast network of our dedicated employees. Features: PTFE seats are providing consistent perfomance with min.maintance

...more

PTFE back up ring

Back-up rings are normally supplied as a spiral of two turns. This enables the back-up ring to be opened with ease for fitting over a shaft, and ensures the 'O' ring is supported around its entire diameter. Single turn back-up rings can also be supplied, and these are usually endless to ensure good support. However, they can be scarf split if required, although we do not recommend this because extrusion can occur at the split.Smaller sizes of back-up rings are available only as a single turn. This is because spiral back-up rings need an inside diameter of 3mm or greater for machining purposes. Materials Our back-up rings are manufactured in either virgin PTFE, PEEK™ (from Victrex plc) or filled PTFE, depending on the application. Why use back-up rings? Back-up rings are installed to prevent extrusion of the 'O' ring. Two back-up rings - one either side of the 'O' ring in its housing - are needed when the application is double acting.They are normally recommended for applications where:Pressure of the fluid medium exceeds 10MPa, or'O' rings of low strength elastomer are used, or Adverse mechanical conditions prevail.

...more

Piston Ring Set

Air Compressor Spares

We are manufacturer & exporter of a wide range of products which include air compressors such as air cooled compressors, lubricated compressor, screw air compressors, high pressure air compressors, reciprocating air compressors, piston air compressors and many more items.

...more

GAS AND AIR COMPRESSOR SPARES FOR HIGH PRESSURE

Manufacturer & Exporter of a wide range of products which include Air Compressors such as Air Cooled Compressors, Lubricated Compressor, Screw Air Compressors, High Pressure Air Compressors, Reciprocating Air Compressors, Piston Air Compressors and many more items. Air compressors are the equipments which are used in several mechanical systems to convert the power from electric motor or diesel motor into kinetic energy by compressing the air to highly pressurized levels. These air compressors are being manufactured at our company using very tough and tensile quality raw materials and in an excellent finishing which retains its reliability for a long term use. We are offering these air compressors to our clients at a very reasonable and conventional range of prices in each and every part of the country as well as in several other countries also. Features: Easily affordable Reliable and trusted Superb efficiency Long lasting Low consumption

...more

Compressor Replacement Parts

We are one of the well-reputed and established manufacturers and suppliers of an high quality array of ptfe compressor parts. These are manufactured using superior quality material which ensures durability.the filled teflon® (ptfe) that we process are suitable for serving nearly every identifiable market at both the oem and after-market levels. These can also be employed by plastics distributors and machine shops that serve oem's.

...more

COMPRESSOR REPLACEMENT PARTS FROM PTFE

We are one of the well-reputed and established manufacturers and suppliers of an high quality array of PTFE Compressor Parts. These are manufactured using superior quality material which ensures durability.The filled Teflon® (PTFE) that we process are suitable for serving nearly every identifiable market at both the OEM and after-market levels. These can also be employed by plastics distributors and machine shops that serve OEM's. The Parts display exemplary performance characteristics and have a long service life even under critical conditions. We offer a huge variety of these products. Some of these include: Piston Rings Wearing Rings Rider Rings Seal Rings Bearing Rings Gland Packing Shaft Bearing

...moreBe first to Rate

Rate ThisOpening Hours