Flush Bottom Valves

6,000 - 40,000 Per Piece

2 Piece (MOQ)

Y Type Flush Bottom Valve

Get Price Quote

100 Pieces (MOQ)

Best Deals from Flush Bottom Valves

IC Flush Bottom Ball Valve

1,100 Per Piece

5 Piece(s) (MOQ)

Flush Bottom Valves

Get Price Quote

Our team members and quality auditors keep regular checks on the quality of products and thus, even the raw material used is tested under vigil supervision to ensure better quality products. Rely on us and place orders with us, timely deliveries will be straight to your doorstep!

Stainless Steel Flush Bottom Flanged Ball Valve

Get Price Quote

Flush Bottom Valve

20,000 Per unit

Flush Bottom Ball Valve

Get Price Quote

We offer flush bottom ball valve. Jupiter controls valves flush bottom ball valve have been proven in service application for over 8 years. Jupiter controls manufacturers and expoerter of high performance flush bottom tank ball valve as per international design to get 100% client satisfaction, continuous repeat purchase order along with total interchangeability, class one quality, workmanship & best service. Mostly flush bottom tank ball valve body is modified by adding inlet oversize flanges. As example: 3" x 4" flush bottom ball valve has the nominal bore of 3" (dn 80), the inlet flange (vessel side) dimensions as per 4(dn100) and outlet flange size as per 3"(dn 80). Flange drilling can be any international standard as per choice of customer. It allows sufficient space for bolting clearance to mount valve & insulation at vessel bottom flange. As manufacturing standard of jupiter controls, flush bottom ball valve seat design is as per fire safe design api 607, solid ball with iso 5211 mounting pad optional. Valve body optopms are carbon steel (astm a 216 gr. Wcb) stainless steel (astm 351 gr. cf8cf8mcf3cf3mcn7m) fabricated ss 304316304l316lalloy20hast alloylow temperature (ltcs) carbon steel material. Flush bottom ball valve, flush bottom ball valve manufacturer, flush bottom ball valve exporter, flush bottom ball valve supplier, flush bottom ball valve stockiest, flush bottom ball valve pneumatic operated, flush bottom ball valve actuator operated, flush bottom ball valve remote operated, flush bottom tank valve, y type flush bottom valve manufacturer, y type flush bottom valve manufacturers, flush bottom ball valves, flush bottom ball valve manufacturers, flush bottom ball valve exporters, flush bottom ball valve suppliers, flush bottom ball valve india, pneumatic operated flush bottom ball valve, actuator operated flush bottom ball valve, remote operated flush bottom ball valve, y type flush tank bottom valves, y type jacketed flush bottom tank valve,

Flush Bottom Ball Valve

Get Price Quote

Specifications Model FTB Design Flush Bottom Wafer type Ball Valve Body WCB CF8 CF8M CF3M Body Seat PTFE GFT CFT PEEK TFM Size 1" to 12" Ball CF8 CF8M CF3M Seals PTFE Temprature up to 180° C Pressure Up to 10 BAR Ends Flanged End 150 Class.

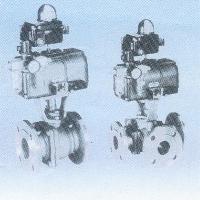

Electrical Actuator Operated Flush Bottom Reduce Bore Ball Valves

Get Price Quote

Owing to our speedy distribution network, we are capable to render quickly and hassle free deliveries. Ours is a reckoned name in this domain and actively involved in offering quality-centralized product range that is designed and developed using the qualitative raw material. Electrical Actuator Details: Manufacturer - Cair Euromatic Automation Pvt. Ltd. Brand / Model - Cair / Mod Approvals - Design (Tuv) / Iso 9001:2008 / Ce / Iec Characteristic - On - Off Type / Modulating Type Travel Angle - 90 Degree Indicator - Continuous Position Indicator Supply - 220v Ac , 50 Hz Body Material - Aluminum Alloy Ambient Temperatre = -10°c ~ 55°c Motor Insulation - Class F Protection Class - Ip 67 – Weather Proof Limit Switch - 1 No + 1 No Output Of 220v Ac Position On Power Fail - Stay Put Manual Override - Provided Details Size - 6”X8” / 8”X10” / 10”X12” / 12”X14” MOC - WCB / CF8 / CF8M Seals - PTFE / CFT/ GFT/TFM/ PEEK Pressure - 150# Temp = Upto 180°C / 250°C Class - 150# Ends - Flanged Type

Flush Bottom Tank Valve

8,500 - 150,000 Per Bag

2 Bag(s) (MOQ)

The acme quality Flush Bottom Tank Valve manufactured by us is used in drainage operations. They are designed to provide effective dead space shutoff for vessels, storage tanks, etc. Our Flush Bottom Tank Valve is available in different specifications and sizes. They are manufactured in different types: Flush Mount Bottom Tank Valve, Disc Type Tank Bottom, etc. Features Made from fine grade quality steel Reasonable prices Customized Flush Bottom Tank Valves are available. High durability and efficiency

Flush Bottom Valve

1,000 - 8,000 Per Piece

1 Piece (MOQ)

A flush bottom valve is a type of valve that is commonly used in the water treatment industry. It is designed to provide a convenient and reliable way to drain liquids and slurries from tanks or vessels. The valve is installed at the bottom of the tank, and its flush design allows for complete drainage of the contents.

PTFE Lined Flushed Bottom Valve

Get Price Quote

Flush Bottom Valve has been designed for use in highly corrosive liquid services. The heavy duty construction of this valve features a cast ductile iron body with corrosion resistant fluropolymer lining.

Flush Bottom Ball Valve

3,500 Per Piece

Flush Bottom Valve

2,500 Per Piece

Lined Flush Bottom Valve

8,000 - 100,000 Per Piece

1 Piece (MOQ)

Lined Flush Bottom Valve

1,500 Per Piece

Lined Y Type Flush Bottom Valve

Get Price Quote

Use of Lined Y type Flush Bottom Valve are made to discharge liquids as well as slurry right from bottom of any Reactors, Receivers or any huge Tanks. We are one of the leading distributors of this product in the market which are manufactured by some of the top notch companies of the industry. We have with us wide range of Lined Y type Flush Bottom Valve which is carefully designed using finest quality raw materials. Proper quality test is done by the experts before dispatching the same to the client location. We accept customized orders after confirming from our manufacturers. Robust body Long shield life Reliable in performance If you are looking for more information for this product then feel free to connect with us. We will assist you to make the right selection. We offer the product at very reasonable price.

Flush Bottom Valves

Get Price Quote

FLUSH BOTTOM TANK VALVE Manufacturer of PTFEFEPPFA PPLined flush bottom valves and sizes as per customer's requirements.

blow down valve

Get Price Quote

Flosteer Boiler Blow Down Valves are Bolted Bonnet Design & Parallel Slide Type. Flosteer Boiler Blow Down Valves are available with Rack & Pinion arrangement for easy and quick operation. Stellited trims are provided for all above 600# as a manufacturing standard of “FLOSTEER” valves and in lower rating also on request. Deep stuffing box is providing to assure tightness and maximum packing life.

Flush Bottom Valve

Get Price Quote

PFA Lined Flush Bottom Valve

20,000 Per Piece

blow down valve

11,750 Per Piece

flush bottom tank valves

Get Price Quote

Functioning of Y Type Flush Bottom valve:- The parts of the flush bottom valve are identical to that of a globe valve and the closing and opening actions are also similar. The shut off is achieved by disk closing against the body seat. The disks in closed position match with the bottom of the vessel or piping leaving no room for hold up or stagnation. Normally, the inlet size of a standard flush bottom valve is one size higher than that of the outlet size. There are special constructions possible with both sizes same.The outlet port is at an angle to the inlet port. Normally 45 or 60 degrees deviation is provided.

Flush Bottom Valve

Get Price Quote

Cast Ductile Iron Y Type, Solid Floating Disc Type, Renewable Seat, Inside Vessels Opening, Fully FEP/PFA Lined, Flush Bottom Tank ValveSize Range: 50mm X 40mm to 100mm X 80mm Lining Specification OTHER LINING MATERIAL We offer other lining materials like PTFE, ETFE, ECTFE, PVDF, PP, HDPE LINING THICKNESS Min. 3.0mm/4.0mm overall SPARK TEST Body liners & all wetted parts are spark tested at 20,000 Volts

Flush Bottom Tank Valve

Get Price Quote

“Y” TYPE Flush bottom valves are used to discharge Liquids &Slurry from the bottom of Reactors, Receivers & huge Tanks. “IVE” Flush Bottom valves are available in design of Disc opening into the Tank ( vessel opening design) & Disc lowering (inside valve opening design) into the valve body. Flush bottom valves with disc opening into the tank or opening upwards is the most commonly used. It is used where enough space is available between bottom pad and the starrier of the tank. The mass load inside the tank helps closing & tight shut off the flush bottom valve. KEY FEATURES AND BENEFITS :- Unique design of IVE flush bottom valves assure “Zero- Hold Up” in the bottom pad of the tank. And facilitate the free flow and quick discharge of the liquid or slurry through the valves. Casted and fabricated in all available metallurgy, Carbon Steel, S.S 304, S.S 316, S.S 304L, S.S 316L, Alloy 20, Hast alloy and as per special specifications. Conical Metal to Metal disc seating/ PTFE seating with option of fixed or Renewable seat. Further metal seating can be hard faced by Stellite TM where distortion of seat by aggressive liquid or slurry is common. Valves available in the size range of 15 NB to 250 NB in BS, ANSI & DIN standards. Available in the design of Jacketed, Actuated & Lined. Offered for Sanitaryaseptic application. IVE Flush Bottom vales can also be provided with the temperature sensors to measure the temperature in the vessel. Bolted Stuffing Box (Gland), easily adjustable & with Repackable service. Rinsing & Non Rinsing stem with outside ACME thread.

Flush Bottom Valves

Get Price Quote

Flush bottom valves, Generally Flush Bottom Ball Valve body is modified by adding Inlet oversize flanges. As example: 2" x 3" Flush Bottom Ball Valve has the nominal bore of 2" (DN 50), the Inlet flange (Vessel Side) size is 3"(DN 80) and outlet flange size 2. It allows enough space for bolting clearance & insulation at vessel bottom flange. At the time of enquiry and order below technical details & dimensions are must required, which is as under: Center Bottom hole of Vessel Vessel Bottom Flange Pad Thickness + Vessel Plate Thickness Vessel Bottom Flange Drilling Standard

Flush Bottom Ball Valve

8,000 Per Piece

Bottom Discharge Rotary Airlock Valve

Get Price Quote

When used to seal Bottom Discharge of a dust collector handling a relatively light dust load and operating at not more than 300 mm W.G. static pressure the light series Rotary Airlock will generally suffice. For a heavier dust loading and higher pressure or other materials handling and feeding applications a heavy duty gravity discharge feeder should be used.

Tank Bottom Valve Manual

Get Price Quote

Series 50 manually operated tank bottom valve has a body with attached welding neck and an inlet ports, a diaphragm seal, a bonnet, and a handle. Key Features: Compact design for space restricted applications Simplified welding with provision of welding neck Optimized flow geometry Hermetical separation of fluids from the operating mechanism by diaphragm Fully machined from SS 316L bar-stock – no welded components CIP/SIP capable and crevice free Zero dead leg and self-draining capabilities Fully Autoclavable Various internal surface finish available each with less than 0.40 Ra.

parallel slide blow down valves

Get Price Quote

NOTES: The sliding discs & seats tested for anti-seize Operation. Operation by Rack & Pinion gives full opening with half turn of the Box key. Locking arrangement in the gland is devised in such a way that the Box key can not be removed while the valve is open. All the Working Parts of S.S. Also Available as per TABLE-‘J’ on Request. TABLE-‘J’ for working steam press. Above 250 up to 350 Lbs/sq.inTEMP. 8000 F (427 C)