Metal Melting Furnaces Parts

Get Price Quote

Metal Melting Furnaces offered comprise soft-start mode and allows any time start or stop without having any impact on power supply. Further, it provides for fast smelting support as well as has low production costs. Some of its features include providing for environment-friendly working support, allows for complete dumping of dissolved material, comes with option of power adjustment flexibility, allows for smooth adjustment support, allows easy controlling of temperature uniformity, steel/cast aluminum based furnace shell for lasting performance, allows for automatic angle adjustment of inverter circuit among others.

Furnace Lining Vibrator

Get Price Quote

If you are in search of a quality furnace lining vibrator, then your search ends with Refcast Corporation. Established in 2013, with a vision to help create a strong bond with companies in need of services. This includes aluminium products, industrial minerals like fused silica powder, silica sand, ramming mass, bentonite clay, lining vibrators, and a lot more. Located in Ahmedabad we are manufacturers, exporters, importers, and suppliers of quality material which has helped us gain a name as furnace lining vibrator exporter. Being in the business since 2013, we have the industry experience and skills. Industry trends change and we evolve according to the changing needs of our customers and what they require. Ordering in bulk and enjoy some unbelievable prices and deals that in turn will bring you profit. Furnace lining vibrator helps in removing any cracks and gas pockets on refractory. Helps by extending the life of the inventory. It also helps in compacting the refractory material with equal density. As your furnace lining vibrator manufacturer Gujarat, we have some great quotes waiting for you. We Are A Sincere Furnace Lining Vibrator Importer We have a team of professionals who understand and work round the clock. We deliver on time maintaining all quality and international standards

Best Deals from Furnace Parts

Furnace Water Cooled Lead

10,000 Per Piece

1 Piece (MOQ)

Induction Furnace Melting Coil

Get Price Quote

10 Piece (MOQ)

Vibrating Furnace Charger

Get Price Quote

1 Piece (MOQ)

biomass pellet bhatti

61,000 - 95,000 Per 1

1 Piece (MOQ)

Continues pellet feeding stove with attachment

Furnace Gas Fire Burner

Get Price Quote

We are offering excellence in the form of Gas Fire Burner With Furnace to enhance the buyers' content. We are strongly backed by a well maintained and managed storage house wherein we store our products for meeting urgent and massive requirements of the buyers.

Industrial Pellet Burner

Get Price Quote

We offer industrial pellet burner. Industrial pellet burner is lower cost of fuel compared to oil (hsdldofo) & gas (lpgpngcngpropane). It is storage silo provision for fuel storage & to avoid frequent re-filling of fuel during process.it is very small ash content as residue after burning i.e. @5%

Boiler Furnace Door

8,100 - 9,100 Per piece

03 piece (MOQ)

Boiler Furnace Door offeredfeatures precision construction standards that provides in it long service life as well as optimum functional efficiency. With high hot-efficiency, these grates comprises frame and grate piece of two parts with links developed using cast iron. Some of its features include come with necessary ventilation gap between piece and piece & bottom for adjusting space ventilation room of air volume, grate available with choice of reciprocating, vibration, stationary, portable and feeding type options, choice of OEM as per the specifications provided by the customers.Features: Model – Fire Door Material – Gr.CI Casting Application – Power Plant, Steel Plant

Ladle Pre Heater

Get Price Quote

1 Set(s) (MOQ)

We are offering ladle pre heater. Salient features : easy to operate fuel : lpg diesel kerosene efficient sturdy design

Industrial Gas Burner

35,000 Per Piece

Furnace Roll

300,000 Per Unit

Industrial Gas Burner Two Stage

Get Price Quote

Industrial Gas Burner is the product which utilize in the manufacturing industries to melt down things with the help of heat. Industrial gas burner known as gas burner because the fuel is use to produce heat is gas or natural gas. Heat which is produce by this type of burner is so high. It can be from 200 to 1200 degree temperature. The minute industrial burners introduce in the market the cost of the fuel in heating industries are gone down and the production made double.

Dual Fuel Burner

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

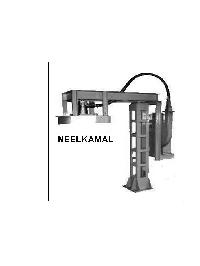

Vibratory Furnace Charger

Get Price Quote

Vibrating Furnace Charges are effective solutions to problems such as high labour cost, hazards to furnace operators faced in foundries, melting shops etc. Such a kind of automation allows foundry men to work at a safe distance thus preventing injures arising out of molten metal splash. It also facilitates in rapid and quick charging of the furnace thereby allowing maximum utilization of the furnace. In addition to this, the damage to furnace lining is avoided which normally occurs in manual charging of the furnaces. The required amount of scrap metal is loaded into the storage hoper at the loading point. The trolley the carries the vibrating feeder along with the storage hopper to the furnace charging point. Here, the vibrating feeder is energized and the material is effectively discharged into the furnace as per the required capacity. As the metal is melted down, fresh batch of metal can be fed into the furnace thereby keeping the furnace full. The capacity of the vibrating feeder can be varied by varying the amplitude of variations. The amplitude of vibrations can be varied by adjusting the position of centrifugal weights or by using a variable frequency drive (optional). A control panel specially designed to suit individual client requirement depending on the sequence of operations required is provided. Specifications : Output Size: 120-200mesh Power: 1.1kw Trademark: JXSC Origin: Jiangxi, China Type: Crushing Equipment Loading Weight:

Vibratory Furnace Chargers

Get Price Quote

Vibrating Furnace Charges are effective solutions to problems such as high labour cost, hazards to furnace operators faced in foundries, melting shops etc. Such a kind of automation allows foundry men to work at a safe distance thus preventing injures arising out of molten metal splash. It also facilitates in rapid and quick charging of the furnace thereby allowing maximum utilization of the furnace. In addition to this, the damage to furnace lining is avoided which normally occurs in manual charging of the furnaces. The required amount of scrap metal is loaded into the storage hoper at the loading point. The trolley the carries the vibrating feeder along with the storage hopper to the furnace charging point. Here, the vibrating feeder is energized and the material is effectively discharged into the furnace as per the required capacity. As the metal is melted down, fresh batch of metal can be fed into the furnace thereby keeping the furnace full. The capacity of the vibrating feeder can be varied by varying the amplitude of variations. The amplitude of vibrations can be varied by adjusting the position of centrifugal weights or by using a variable frequency drive (optional). A control panel specially designed to suit individual client requirement depending on the sequence of operations required is provided.

induction furnace spare parts

Get Price Quote

induction furnace spare parts, Induction Furnace

Ice Cream Hardening Tunnel

332,000 Per Piece

1 Piece (MOQ)

Biomass Wood Pellet Burner

80,000 Per Piece

Vibratory Furnace Charger

Get Price Quote

Jaykrishna magnetics manufacturer vibrating furnace charges are effective solutions to problems such as higher labor cost, hazards to fund operators faced in foundries, melting shops etc. Such a kind of automation allows foundry men to work at a safe distance thus preventing injuries arising out of molten splash.