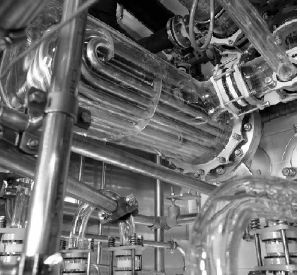

glass shell tube heat exchanger

Get Price Quote

Shell and tube heat exchanger provides a versatile alternative to the coil-type heat exchanger described in previous pages. Shell and tube heat exchanger is particularly suitable for applications where large heat transfer area is required in relatively confined spaces. It is equally suitable for heat transfer between two liquids or gases. Shell & tube heat exchanger is available in single-pass as well as multi – pass.Both versions are available with glass or mild steel shells in combination with glass tubes as standard. Consequently, there are three basic models. SALIENT FEATURES Universal corrosion resistance Outstanding heat transfer Space-saving arrangement by installing in horizontal or vertical position Simple replacement of inner tubes for repair and cleaning Low maintenance cost Available in wide range of HTAs. CONSTRUCTION FEATURES The glass tubes are individually sealed in the PTFE tube plates using threaded bushes. The special construction ensures permanent tightness and easy replacement and cleaning of tubes, Baffles on shell side ensure improved heat transfer by increased turbulance.Sealing principle similar on all methods : Metal Cover (Bonnet) PTFE Tube Plate (Tube Sheet) Threaded Bush Glass Tube Baffle Glass Shell PTFE Tube TaiRod in PTFE Cast Iron SS Flange Springs Screwed Rod or Nut Insert Flat Washer OPERATING RANGE : The maximum permissible operating conditions in borosilicate glass 3.3heat exchangers are detailed in the table below.

Glass Heat Exchanger

Get Price Quote

10 Piece (MOQ)

Optimum Solution for every requirement A range of designs available & in modular construction Wide range of duties namely ; Condensation, Cooling, Heating, Boiling & Evaporation Material of construction comprise of a combination of highly corrosion resistant materials including Borosilicate 3.3 Glass , SiC, Fluoropolymers (PTFE, PFA, FEP, PP) & Exotic metals (Ta, Nb, Ti, Zr, etc) Fabricated with all major internationally prevalent buttress designs and having a very high reliability of the strong and high-duty coupling system used for all components Non-standard & special custom designed can also be supplied to special order.

Best Deals from Glass Heat Exchanger

glass heat exchangers

10,000 - 70,000 Per

1 Piece (MOQ)

Glass Shell and Tube Heat Exchangers

85,000 - 16,000,000 Per Set

1 Set (MOQ)

UD Technologies is a manufacturer and designer for Glass Shell and Tube Heat Exchangers for various duties such as: Heating Cooling Single component Condensation Multi-component condensation Thermosyphon reboiler Falling Film Evaporators Falling Film Absorbers Waste Heat Economisers along with adjoining pipelines and equipment Glass Shell And Tube Heat Exchanger-Visual Process Control In order to cement our position, we are successfully presenting a wide and quality assured gamut of Glass Shell And Tube Heat Exchanger. Offered heat exchanger is designed well by our capable professionals. Available in several technical specifications, provided heat exchanger is greatly demanded in the market for its brilliant feature like hassle free performance, low maintenance and precision-designed. In addition to the classical Glass heat exchangers in the coil or shell and tube construction form, UD offers you a variety of process-specific Equipment. Our Process engineering division would be happy to help you with a layout design Shell and tube heat exchangers: Our Heat Exchangers are designed and built such that nearly all removable Parts like Shell, Tube Sheet, Tubes, Bonnet Glass Shell and Tube Heat Exchangers are available upto 40 Sq. Mt Heat transfer Area Metal Shell and Glass Tube Heat exchangers are Avialble up to 50 Sq. Mt area Heat transfer Application Condensation on Shell Side Condensation on tube Side Falling Film Evaporator Thermosyphon Reboiler Waste heat Economiser Heating -Cooling Application Climbing Film Evaporator or Recirculatory Evaporation Falling Film Reactor and Absorber We also offer Shell and Graphite tubes heat exchangers with Shell options of Glass – MS-SS. Bonnets are also available with Glass –Graphite – Metal as per process requirements Salient Features : Universal Corrosion Resistance Outstanding heat transfer Space-saving arrangement by installing in Horizontal or Vertical position Simple replacement of inner tubes for repair and cleaning Low Maintenance cost Coil type heat exchangers: Flexibility to increase Heat Transfer Area by adding more modules UD Technologies Manufacturers Coil Heat Exchangers from 0.2 Sq. Meter to 4 Sq, Meter Heat transfer Area UD technologies Designs ,Manufacturers ,Supplies Heat Exchanger for Highly corrossive Environments and different Process requirements like condnesation ,Thermosyphon Reboiler ,Heating-Cooiling and vaporization UD Selects MOC from Borosilicate Glass-Graphite-PTFE and Some Exotic metals Like Tantalum Offers from Smaller Heat transfer Area 0.2 Meter Square to 30 Sq, Mt

Glass Heat Exchanger

7,500 - 75,000 Per Piece

1 Piece(s) (MOQ)

Glass Heat Exchanger

Get Price Quote

Shell & tube heat exchangers offer large surface area in combination with efficient heat transfer and compactness. These are widely used in industries for various duties like cooling, heating, condensation, evaporation etc. GOEL are the pioneers in the field of glass shell and tube heat exchangers in India and their product has a wide market acceptability. Salient Features of Shell and Tube Heat Exchanger : 1.Universal corrosion resistance an excellent alternative to expensive MOCs like graphite, hastelloy, copper titanium, tantalum and other exotic metals. 2. Excellent heat transfer as fouling does not occur on smooth glass surfaces. 3. Flexibility of installation verticalhorizontal. 4. Easy replacement of tubes for repair and cleaning. 5. Available in wide range of HTAs. 6. Ease of installation due to light weight. 7. Economical. 8. Suitable for applications where large HTAs are required in limited space. Advantages of Shell and Tube Heat Exchanger Over Conventional Coil Type Heat Exchangers : 1. The overall heat transfer coefficient in shell and tube heat exchanger is about 3 times higher than in coil type heat exchanger. 2. The pressure drop in shell and tube heat exchanger is minimal compared to 2-3 kgcm2 in coil side of coil type heat exchanger. 3. For requirement of higher heat transfer areas shell and tube heat exchanger is the only alternative.

Glass Heat Exchanger

Get Price Quote

The overall heat transfer co-efficient of Borosilicate glass equipment is comparatively favourable with many alternative materials because of its smooth surface which improves the thermal coefficient & reduce the tendency of fouling. Heat Exchangers are available in 2 basics designs: 1. Conventional Coil Type Condensers. 2. Shell & Tube Type.

Glass Heat Exchanger

6,000 Per Unit

Glass Shell and Tube Heat Exchanger

Get Price Quote

Glass Heat Exchanger

Get Price Quote

We make available our Glass Heat Exchanger in two categories, namely Coil type and Shell & Tube type. It can be used for variety of applications such as condensation, cooling, heating, boiling and suitable combinations of the above. Moreover, the selection of equipment depends upon the type of application, heat load, availability of heating/cooling media and various other factors. Moreover, our Glass Heat Exchanger is reasonably priced. Functioning :In all types of glass Heat Exchangers the heat transfer is through the wall of the glass tube. The heat transfer co-efficient can be of a moderate order because of low wall thickness. With 1.5 mm thick walled tubes, the wall heat transfer co-efficient is about 725 Kcals/hr m2oC and we can obtain an overall heat transfer co-efficient for steam condensation with water-cooling as about 550 Kcals/hr m2oC. The allowable pressure inside the tubes can be vacuum to 3 kg/cm2 while that on the domes as well as on the shell depends upon the size of the shell corresponding to the values mentioned in technical specifications. The Heat Exchangers can safely be used up to 150oC with the limitations of thermal shock up to 120oC and temperature gradient across the wall less than 50oC. The shell side pressures on metallic shell & tube heat exchangers can be as high as 2.5 kg/cm. For higher pressure requirement up to 4 kg/cm2 , the PTFE tube sheets need redesigning and can be made on special request.Available Types : Coil Condensers Product Coolers Immersion Heaters Boilers Coil Condensers, InformationComposed completely of glass, coil heat exchangers are typically used as vapor condensers and liquid coolers. They are usually designed and installed as an integral part of a vertical column. To provide a reliable corrosion resistant internal seal, the coil battery is sealed to the jacket, creating a single unit. Boilers and immersion heaters are also available in this all-glass coil design.Other DesignsWe also offer glass cascade coolers, bayonet and jacketed-type heat exchangers. For further information on these special application models, please contact us.Technical Data Heat Transfer in CondensersThe heat transferred in coil condensers con be considered generally as 55 Btu/hr-ft2-oF for any unit. This figure may vary from 10 to 72 Btu/hr-ft2-oF depending on the fluids involved and the operating conditions.

Glass Shell and Tube Heat Exchangers

Get Price Quote

Shell and tube Heat Exchanger are for large heat transfer area, the efficiency of heat transfer and compactness. Shell and Tube Heat Exchanger are widely used as coolers, Condensers, Heaters and Evaporators. Glass Shell and Tube Heat Exchangers are reliable only when leak-free sealing is available between shell & Tube sides. There are two types of Ferrule Sealing in Sigma shell and tube Heat exchangers. Such as: PTFE Ferrule with Gland Packing. PTFE Ferrule without Gland packing. In the case of Ferrule seal with gland packing PTFE ‘O’ Ring & PTFE Rope is used to fill the space between tube and tube sheet and PTFE Ferrule acts as a Gland Follower to make sealing perfect and leak free. And Ferrule without gland packing is a sealing system where the design of ferrule is such that while tightening. The ferrule gets folded at the seal point of Tube – Sheet in such a way that it does not require ‘O’ Ring or the gland rope and gives as good leak free sealing as in the first case. This unique ferrule type sealing arrangement permits easy replacement and cleaning of tubes. Sigma has further improvised on the shell and Tube Evaporators and Re-Boilers with the replacement of Glass Tube by Graphite Tubes and GFT Tube – Sheets. These types are good for high temperature and high-pressure application.

Glass Heat Exchanger

Get Price Quote

Glass heat exchanger offer large surface area in combination with efficient heat transfer and compactness. These are widely used in industries for various duties like cooling, heating, condensation, evaporation etc. GOEL are the pioneers in the field of glass shell and tube heat exchangers in India and their product has a wide market acceptability.

Glass Heat Exchanger

Get Price Quote

We are instruments in offering a proven range of glass heat exchanger, which is manufactured with precision using advanced machines. The glass heat exchanger offered by us, is known for its high performance and longer working life. Further, glass heat exchanger is available in two types i.e. Coil type and shell and tube type heat exchangers. Range coil type heat exchangers immersion heat exchanger sproduct coolers shell and tube heat exchangers

Glass Tube Heat Exchanger

Get Price Quote

Shell & Tube Heat Exchangers are used in place of conventional coil type glass condensers where large heat transfer areas are required in confined spaces.

Glass Shell and Tube Heat Exchanger

Get Price Quote

Glass Heat Exchanger

5,000 Per Number

1 Number (MOQ)

Glass Shell and Tube Heat Exchanger

50,000 Per Set

1 Set (MOQ)

borosilicate glass heat exchangers

Get Price Quote

borosilicate glass heat exchangers, Industrial Glassware, Nylon Braided Hoses

glass heat exchangers

Get Price Quote

glass heat exchangers, scientific glass equipments, Laboratory Glassware

Glass Heat Exchanger

Get Price Quote

Glass Heat Exchanger, Industrial Condenser, Industrial Heat Exchanger