Ultra High Speed Rotary Tablet Press

FEATURES : • In Compliance with cGMP Guidelines • Turret of SG IRON 500/7 Graded Casting • High Speed Double Sided Rotary Tablet Press with Pre-Compression Facility • Maximum Output upto 540000 tablets per hour (for 75 Station) • Easy Accessibility for Quick Cleaning and Product Conversion • Improved Tablet Quality; Handles Difficult Products Easily due to Pre-Compression Facility • Precise Weight Control • Ensures Hygienic Production Conditions and Operator Safety • All Tablet Parameters can be fine tuned during operations from outside the tableting zone • Force Feeding System • Hydraulic Power-Pack System • Auto Lubrication system • Upper punch penetration system • Safety interlocking for upper guards • Front and Easy Outside Controls for machine and tablet parameters • Three Piece Turret with Stainless Steel 316 L die-plate OPTIONAL FEATURES : • Tablet Rejection on Machine Start up and Stop and random sampling device • Powder Level Sensors at Feed Hopper • Tight Punch Detection (Upper Punch) • PLC-MMI Control system with Touch Screen display • Gravity Feeding System • Bi-layer tablet facility • Tablet Sampling

...more

Turn Table

Description:The motorized roller conveyor is having stainless steel structure with roller in the center. Structure made out of S. S. pipe & supported on adjustable bolts, useful to transfer container / object from one place to another place, without human touch by way of roller movement motion. Salient Features: • Structure is made of S.S. 304, 30 mm sq. Pipe, 16 SWG with matt finish.• Minimum Electricity requires• Length can make as per customer requirement.• Adjustable height of conveyor belt, to align with other machine of the line• Self-alignment bearing for easy maintenance.• Rigid Vibration free Construction for trouble free performance

...more

GMP Tanks

Description:GMP Tanks & Vessels are made as per WHO & US FDA standards to storage / manufacture Syrup / Suspension / oral / external liquid for pharmaceuticals. This is a completely fabricated tailor made as required by the customers. Material of construction: All the tanks / vessels are made from S.S. 304 / S.S. 316.CIP/SIP available as per requirements. Available with top lid / without lid.Available with three / four legs.Available with Electrical / Steam operated vessel.Available with glass wool insulation / without insulation.Capacity: From 50 litres To 5000 litres.

Country of Origin : India

Type : Galvanized Tanks

Material : Hot Dipped Galvanized

Shape : Rectangular

Thickness : 10-15mm

Application : Industrial

...more

Tablet Inspection Belt

The machine is mounted on Stainless Steel 304 structure. It consists of 6” wide endless belt at the centre. The belt is driven by 0.5 HP AC motor controlled through AC Variable Frequency Drive. Stainless Steel Hopper is provided from which tablets fall on a magnetic vibrator, which removes chips & dust from the tablets. Two Inspection Lamps and Two Foot Switches for two operators are provided to stop the conveyor when needed. The machine is designed for manual visual inspection of tablets from both the sides. About 7 to 8 Lac (0.7 to 0.8 million) tablets per shift can be inspected depending upon tablet size & operator skill. The output always depends upon tablet size and operator skill. Salient Features • Inspection on both sides of Tablet. • As per cGMP Standard. • Reversible of Tablet. • Foot switch provided on both side for stopping the machine. • Vibration provided for removing of Dust. • The unit is mounted on caster wheel. • 0.5 HP AC motor controlled through AC Variable Frequency Drive

...more

Tablet Filling Attachment

This is special purpose tablet filling attachment for Semi Automatic Capsule Filling Machine With Line to insert one OR two tablets in one capsule, It is made as per the sample of tablet for any Semi Automatic Capsule Filling Machine With Line

...more

Tablet De-Dusting Machine Elevating Type

FEATURES : • Tablet movement is in upward direction – Bottom to Top.• De-dusting of tablets through upward direction & compressed air.• Machine can be attached with Tablet Press for De-Dusting of the Tablets & Elevating of the same for further connection to the Metal Detector.• It works on the principle of vibration, which causes elevating type movement of the Tablets.• All Contact Parts are made of SS 316.• The stand is made from stainless steel which height is adjustable to connect with various Tablet PressMachines.

...more

Tablet De-Dusting Machine

FEATURES : • Highest possible effective de-dusting & de-burring of the tablets by means of vibratory effect. • Discharged tablets from the Tablet Press are entered to the top of the Tablet De-Dusting Machine and finallypassed through elegantly designed perforated spiral which gently vibrated to release the layer of surface dust & remove the edges.• Geometrically designed tablet conveying route to ensure easy removal of dust & burrs.• All contact parts are easily accessible for washing.• Compliance with cGMP standards with all products contact parts made of SS 316.• Unique design for de-dusting & de-burring of tablets.• Easy to Install, noiseless & maintenance free unit.• Less electric power consumption compare to other units of its kind.• Adjustable height facility to suit with any Tablet Presses.• More efficient De-dusting results can achieve by connecting the separate Dust Extractor with the machine.• Compatible with all type of Tablet Presses and Dust Extractors.• Castor wheels for free mobility• Brushing Unit attachment – Optional

...more

Swing Conveyor Belt

Description:The swing conveyor belt is having stainless steel structure with moving S.S. slat chain of width 3 ½” in the center. Structure made out of S. S. square pipe & supported on adjustable bolts. Is useful to transfer container from one place to another place, without human touch also to fit between two join and use as way path by swinging arrangements. The conveyor belt brings the container from the other machine, these bottles transfer from a machine to another machine with out human touch, adjustable guide provided to set accordingly diameter or width of container,with arrangement to swing conveyor at 90° Salient Features: • Structure is made of S.S. 304, 30 mm sq. Pipe, 16 SWG • with matt finish.• Swing up to 90° (180° on custom demand) • A/c frequency variable drive.• Direct gear drive.• Length can make as per customer requirement.• UHMW self-lubrication guide below chain.• Adjustable height of conveyor belt, to align with other machine of the line• Self-alignment bearing for easy maintenance.• Rigid Vibration free Construction for trouble free performance

...more

Swing Conveyor

The swing conveyor belt is having stainless steel structure with moving S.S. slat chain of width 3 ½” in the center. Structure made out of S. S. square pipe & supported on adjustable bolts. Is useful to transfer container from one place to another place, without human touch also to fit between two join and use as way path by swinging arrangements.

...more

Stirrer Homoginizer

Descriptions:“GMP’S” Homogenizer is built on heavy structure stand to minimize vibration, consist of stand, motor, shaft, stator & rotor. Homogenization technology is based on the use of pressure on liquids to subdivide particles or droplets present in fluids into the very smallest sizes (submicron) and create a stable dispersion ideal for further processing. This equipment produces very high pressure through a specially designed stator & rotor and homogenizes liquids. The head is made out of stainless steel with a telescopic stand. Operation: A homogenizer is a single acting stator & rotor, able to create the pressure used to micronized various products. Homogenizers can apply dynamic pressure under continuous flow conditions, processing fluids like emulsions and dispersions for a large variety of applications, viscosities and physical properties. GMP homogenizers are available in a wide range of high pressure and low pressure models providing throughputs at continuous working pressures. Custom engineered solutions and special versions for specific applications are available across the range, and a wide selection of options helps to define machine features which fit exactly into customer and process requirements for any industry application. Salient Feature: • 1H.P. to 10H.P.• Built on Fix or telescopic stand or available with tank/vessels.• cGMP design• Low or High RPM also available with variable speed.• Sleek and Sturdy design• Low noise• Smooth start and stop• Higher speed range & constant torque with precise speed control• Overload safety cut off• Maintenance and spark free AC induction motor• Digital speed display• Vertical positioning gear system for smooth and vibration free movement of the stirrer assembly for height adjustment

...more

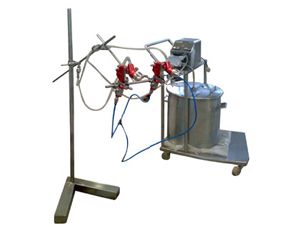

Spraying Unit for Coating Pan

SALIENT FEATURES : • In compliance with cGMP guidelines. • The unit is designed to replace the conventional manual coating system of tablets/granules. • Circular shape solution tank is provided with loose top lid with 1/3 portion pin hinging for opening. • Both dosing container and electrically operated peristaltic pump mounted on the movable trolley for production convenience. • The solution spraying gun is mounted on the individual Stainless Steel 304 make stand having flexible arm for spraying gun positioning. • Spraying gun connection having two ports connection for liquid and air. • An air regulator is placed at the air inlet of the spraying gun to control the spray. • Stirrer for mixing the solution can be provided with variable speed facility (OPTIOANL) • Stainless Steel 304 make operating panel is provided with the system. • Inside surface of the tank is mirror polished & outside matt finish. • Spraying system consist of peristaltic pump, spraying nozzle with stand, air flow regulator, pneumatic pipe, solution conveying pipe, spraying gun. • Available in 25, 40, 50, 100 & 200 Liter capacity of tank.

...more

Slat Conveyor Belt

Description:The slat conveyor belt is having stainless steel structure with moving S.S. slat chain of width 3 ½” in the center. Structure made out of S. S. square pipe & supported on adjustable bolts. Is useful to transfer container from one place to another place, without human touch which also reducing manual labors. The conveyor belt brings the container from the other machine, these bottles transfer from a machine to another machine with out human touch, adjustable guide provided to set accordingly diameter or width of container. Salient Features: • Structure is made of SS 304 30 mm sq. Pipe, 16 SWG with matt finish.• A/c frequency variable drive.• Direct gear drive.• Length can make as per customer requirement.• UHMW self-lubrication guide below chain.• Adjustable height of conveyor belt, to align with other machine of the line• Self-alignment bearing for easy maintenance. • Rigid Vibration free Construction for trouble free performance. Optional: • Castor Wheel with lock.

...more

Single Sided Rotary Tableting Machine

Description:It is a square GMP model/single sided Rotary Tablet Press/ promising unmatched quality for small batch Production. Safety/enhanced performance/clean ability and ease of operation is its most significant features. The suitable model can be selected based on the tooling and output requirement from the 16, 20 & 12 station with “D”, “D” & “SPECIAL” tooling respectively. The 12 station model is available with “SPECIAL” tooling and tunnel type cam track having maximum tablet diameter of 40mm & maximum depth of fill of 30mm. SALIENT FEATURES : cGMP • In compliance with cGMP guidelines • Turret of SG IRON 500/7 Graded Casting • Robust with high quality Engineering • Small batch production • Safe/ Simple to operate and easy to maintain • Higher Turret RPM upto 42 • Main Moter AC Variable Frequency Drive (optional) • Force Feeder (optional) • Aluminum covers for Turret teeth

...more

Sifter Machine

Salient Features • In compliance with cGMP guidelines with Low capital cost.• Machine are designed on the principle of gyratory motion generated by double eccentric weight mounted on two ends of the shaft of vertically mounted specially designed vibro motor.• The screening assembly consisting of one or more set of deck/screens is mounted on a set of annularly located springs, effectively isolating the base from vibrating assembly.• The double weight moving with the shafts and located at relative angular position produces three dimensionalvibrations which in turn cause the material falling on the screen mesh move at a specific speed in straight to spiral direction giving controlled and effective screening.• Due to the adjustability of weight and the relative angle between them it is possible to make the material move on the screen in desired path to achieve the desired retention time for effective screening before the material gets discharged from the outlet spout. During this process the particles smaller than the mesh aperture fall through the mesh and the oversize material gets discharged from the outlet spout. This process is repeated on the next mesh in case of multi deck screening.• Available in different models.• Continuous feed – Continuous Discharge • Continuous Screening• Noiseless, Maintenance free & high speed machine.• Better process & pollution control which reduce environmental hazard.• Portable, compact & elegant.• All contact parts and screen of AISI stainless steel 304 material.• AISI stainless steel 316 quality contact parts optional.• Electric power consumption is very less compared to reciprocating vibratory system.• Standard machine are with non flame proof motor explosion proof.• Easy dismantling and cleaning facility for contact parts.• Saving Manpower cost & reduction of in material loss.

...more

Shrink Sleeve Applicator

Machine Features: Automatic operations of sleeve cutting& inserting Easy serviceable Less weight and sturdy Acrylic covers from all sides Shrink tunnel for shrink sleeving the container Structure of SS material Feed screw for feeding the containers Imported AC frequency variable drive make with constant torque PLC will be of standard make Electrical hardware’s for the Panel Motor for sleeve pusher unit Sensor for sensing the Product Essentials: Containers & Sleeves should be of proper quality Material to be used for shrink OPS, PET & PVC Length of Sleeve: 30mm to 200mm Lay flat Width: 40mm to 170mm Electric Supply: 415V +/- 10%, 50Hz, 3 Phase neutral & Earth

...more

Shrink Heating Tunnel

Description:• Adjustable Height.• Variable Speed Roller (mesh) Conveyor• Can be used at floor Height (Detachable Stand) Applications • Stationary, Books, Files, Magazine, Manual, Envelopes• Xerox Paper, Gift Article, Greeting Card,Trophies,Toys & Games• Computer Consumable , Accessories, PCB, Electrical Components, Dry ell Battery Etc.• Pharmaceuticals & Chemical Product • Medical Equipments, Cosmetics, Household Articles • Industrial, Engineering, Automobile Components• Textile & Hardware Articles • Multi Packs, Promotional Materials And More • Fast Food, Confectionary, Beverages & Dairy Product

...more

Semi Automatic Tube Filling Sealing

Description:‘GMP’s’ Tube Filling & Sealing Machine work on volumetric principle The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, Reciprocating Nozzle with self-centering devices & SS Syringe. No tube No filling system arrangement is standard features of the machine. The main drive of the machine A/c Motor with synchronized variable A/c Frequency Drive. Operation: The Tubes are loaded on the subsequent indexing part of rotating platform and are filled in series of operations. Specially designed Tube holders provided to hold Tube with neck diameter. The Tubes are placed in an inverted position in these cup shaped holders. The Nozzle also filling when Tubes are stopped. After filling the sealing head and batch coding device are performing perfect operation of crimping and coding of mfg. date & batch no. etc. Salient Features: • No Tube No Filling & No Crimping System.• Rigid vibration free construction for trouble free performance.• SS Elegantly matt finished body. • Elegant and easy control panel for total control on operation.• Minimum charge overtime, from one size to another container or fill size.• Geneva Mechanism.• Nylon & bearing type Tube Holder.• Easy loading and unloading.• Synchronized A/c drive for variable speed• 51 Ltr. Acid proof hopper• Synchronized A/c drive for variable speed• MCB for over load protection, and prevent against short circuit.• Inbuilt protection against over current, voltage fluctuation, short circuit in A/c frequency drive.• Beam with folding station for metal tube - closure type 1.• Heat sealing unit for Lami Tubes P/1 Comprising Straight Rifles, Oblique Rifles & Plain.• Temperature regulator for Heating Element.• Coding device for coding one side with 10 digit letters.• Blow off for connection to Compressed Air

...more

Screw Cap Sealing Machine

Salient features: the unit is made compact & versatile. S.s. Elegantly matt finished body. built in front control panel. Quick setting. Motorised head movement. No change parts require for different container diameter. Low noise level, low power consumption.

...more

Semi Automatic Capsule Filling Machine With Line

Description :This is Semi Automatic Capsule Filling Machine With Line in our range with an output of 12,000 capsules per hour and suitable for filling capsule of # 00, 0, 1, 2, 3, 4 & 5 with Powder, Pellets & Granules. It is comparable to the best for R & D, Colleges & production for small batches because of its outstanding features. Its advanced design meets the cGMP .

...more

Semi Automatic Capsule Filling Machine With Line with Line

Outstanding Fetures: • High out put Due to more holes per Loading Ring.• Loading Ring M.O.C is light weight Magnesium alloy – easy to carry.• Automatic Capsule’s Cap & Body get separation with help of motor no need to turn by hand.• Filling Table speed – 2 to 14 RPM through VFD Auger Speed – 200 to 500 RPM through VFD.• PLC Controlled with touch screen display.• 50 product recipe storage.• No need to store filled Capsule for Polishing & sorting. On line Polishing & sorting.• No Operator require for Polishing & Sorting.• Machine is supplied with any one size capsule change parts, 03 nos. extra Augers, Pellets Filling attachment &FRL.

...more

semi automatic capsule filling machine

This is Semi Automatic Capsule Filling Machine With Line in our range with an output of 38,000 capsules per hour and suitable for filling capsules of all sizes with powder, pellets & granules. It is comparable to the best because of its outstanding features, both functional and mechanical. It’s innovative design and precision manufacturing meets the requirement of cGMP.

...more

Semi Automatic Cap Sealing Machine

The semi automatic cap sealing machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine. Machine is motorized incorporating rotating threading & sealing rollers, for threading & sealing of ROPP cap.

...more

rotary vial washing machine

Salient Features: Geneva Mechanism. Four inner (Included one air wash) & one outer. Sequence of washes to customer’s choice. Easy operation. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading.

...more

Rotary Bottle Washing Machine

Description:“GMP’s” Rotary Bottle Washing Machine is compact and highly efficient machine with elegant look. This multifunctional multi featured machine meets the GMP requirements of washing for glass and plastic bottles. The machine operates on the rotary principle with "GENEVA" mechanism and requires manual loading and unloading of bottles. The bottles are loaded on the subsequent indexing part of rotating platform and are cleaned in series of operations. Specially designed bottle holders provided to hold bottles with neck diameter. The bottles are placed in an inverted position in these cup shaped holders. Spraying showers does the external cleaning of the bottles. Solenoid valves are provided to enable the regulation of wash timings, it also spraying water when bottle are stopped means insure saving of water, and sequence of various washing media to suit specific requirement. Salient Features: Geneva Mechanism. Four inner (Included one air wash) & one outer. Sequence of washes to customer’s choice. Easy operation. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading. Individual solenoid valve for each washing sequence, that eliminates carbon plate and other accessories reduce leakage and maintenance to minimum. Higher capacity centrifugal pumps to wash bigger bottles (500 & 1000 ml.). The stationary nozzles avoid chipping of bottle necks. Pumps and tanks are mounted on portable stand for easy maintenance. Bottle guide system especially for lightweight bottle. Pumps and Tanks are mounted on Portable stand for Easy Maintenance. Separate panel control to avoid any short circuit due to spraying of water. S.S. glycerin fill pressure meter. Utility Requirement: Electrical supply : 3 Phase + Neutral + EarthingElectrical load : 2 KW + 3KW for heaterAir Pressure: Minimum : 6 bar pressure 5 CFM

...moreBe first to Rate

Rate ThisOpening Hours