Ball Mill

Get Price Quote

We engaged in manufacturing of Ball Mill which are used in heavy duty, continuous type ball milling in that we have three compartment and screen. Replaceable liners are fixed inside entire mill. Liners material and shape is selected based on material to be grind. Input material is fed in two primary grinding compartments. Large diameter balls for reduce particle size are laying inside first compartment. Material comes into second compartment for further grinding. Small size balls are laying inside second compartment. Material comes into third for fine grinding. Smaller size media are laying inside third compartment for fine grinding. Diaphragms may place to regulate material level and control retention time. Material is feed and discharged through hollow trunnion at opposite end. Accessories like air classifier, cyclone, blower, return air circuit or dust collector can also be placed for close loop system. Two tiers fixed on both end of mill, which are rotate on four rollers. Rollers are fixed on support and oil immersed. Mill rotates on four roller and two tiers. Girth gear is fixed on shell, which driven mating gear, gearbox and motor, which are fixed on heavy drive base. continous ball mill jmef continuous ball mill is useful for grinding coarse feed to get fine powder in single continuous operation. It is for grinding ceramics, cement, pencil, paint, chemical, ink, marble, coal, minerals etc. working process: heavy duty, continuous type ball mill with three compartment and screen replaceable liners are fixed inside entire mill liners material and shape is selected based on material to be ground. Material is fed in two primary grinding compartments large diameter balls for reduce particle size lay inside first compartment material comes into second compartment for further grinding small size balls are lying inside second compartment material comes into third for fine grinding

POWER MILL & COLLOID MILL

Get Price Quote

Backed by a team of highly experienced professionals, we are involved in providing a wide range of power mill & colloid mill.

Best Deals from Grinding Mill

Colloid

Get Price Quote

Clit Colloid Mill is suitable for Homogenizing, Emulsifying, Dispersing, Mixing, Comminuting of liquids to highly viscous products. It is based on rotor-stator principle. It is available in plan as well as Water Jacketed model which is suitable for heat sensitive products. Flame Proof electrical can be supplied on demands.

Colloid Mill

Get Price Quote

Product is feed to the operating area of a rotor, having a speed of 2800 R.P.M by specially designed feed device. The product is processed by high sheer, pressure and friction between the stator and rotor, the angular gap becomes narrower towards the discharges section. This processed product continuously leaves the mill through the drain pipe, if required, it can be re-circulated. SALIENT FEATURES All contact parts can be easily and quickly dismantled and cleaned. Machine is designed for continuous operation. Cylindrical screen for higher output. Flame proof electrical can be provided at extra cost.

Grinding Mill

80,000 - 300,000 Per Piece

1 Piece(s) (MOQ)

We are offering cement industry grinding mill. Ball mill: • we are manufacturing both type of ball mill, batch type ball mill & continuous type. • ball mill is widely used in mining, building materials and chemistry industries. • according to the milling way, the ball mill can be divided into dry and wet types according to ways of discharge. • ball mill is useful for both application grinding as well as mixing purpose features: 1. high capacity with lower cost 2. easy maintenance and operation 3. available different type of material for grinding media and liners like ss, ceramic, hi mn. Steel, hi alumina hi chrome, etc… • capacity range: up to 5000 ltr in batch type ball mill up to 10 tph in continuous type ball mill • hardness: up to 9 moh’s scale application: quartz, topaz, feldspar, ceramic, iron ore, chemical ind., mineral ind., etc…….

Ball Mill

Get Price Quote

Details We are manufacturing type of ball, batch type ball mall & continous type. Ball Mill is widely used in mining, building materials and chemical industries. According to the grinding way, the ball mill can be divied into dry and wet types according to ways of discharge ball useful for both application grinding as well as mixing purpose. We offer machine in MS or SS construction with different shape of liner & grinding media having various metals like MS, En, SS, Mn Steel, Hyper Steel etc. for better result &vbest life of wear & tear part.

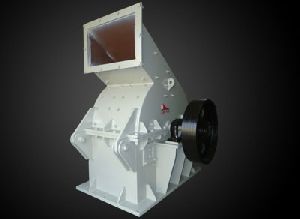

Hammer Mill

Get Price Quote

The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). - A robustly constructed machine for crushing different mineral, chemical, Ayurvedic Herbs, Agro Products, etc... • Capacity Range: 100 - 5000 KG /HR. • Application: Different chemicals, Minerals, Pigment, Coal, and Agricultural Products like Gram, Maize, Rice, Husk, Sawdust, Ayurvedic herbs, Cattle Feed, Animal Feed, Poultry Feed, Refractory, Ceramics, Dolomite, lime stone etc. Features of Hammer Mills 1. Use Hammer Mills without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used.. 2. Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material. 3. Fab-tech Engineers offered different type of material for liners and hammer as per client product for better result and best life of wear & tear part.

Colloid Mill Machine

140,000 - 180,000 Per Nos

10 Piece (MOQ)

batch ball mill

400,000 Per Piece

600 Liter Colloid Mill

90,000 Per Piece

1 Piece (MOQ)

Colloid Mill

Get Price Quote

Ball Mill

Get Price Quote

We offer ball mill. A good range of batch type ball mills to crush even the hardest materials like, quartz, topaz, ceramics, silica, etc. Different types & materials of liners and grinding device is used such as hyper steel, stainless steel, mn. Steel, ceramic etc., may be selected to suit the requirement. application in: where the dusting is not desired and uniform particle size is must. Such as dyes, minerals, etc.

Ball Mill

Get Price Quote

Colloid Mill

Get Price Quote

colloid mill is used for reducing size of solid particles suspended in a liquid. It acts as a good homogenizer and emulsifier in a solution. Colloid mill is also used in reducing the droplet size of a liquid that may be suspended in another liquid. The equipment is specially manufactured in a conical arrangement to achieve the required centrifugal force that maximizes the milling effect. The feeding system is efficient and the machine subjects the product to high forces of shearing, cutting and rubbing forces to create a homogenous mixture.

Industrial Ball Mill

Get Price Quote

Model : 2 HP to 100 HP and above { 5 Kg to 10 tons Capacity / Continue Ball Mill } Direct Gear Drive , Counter Gear for load reduction Contraction : MS + MS / SS Coating + SS + Zeketed Ideal For : Pigment Colors - Minerals & Ores - Chemicals Technical Products Dyestuffs - Fertilizer - Insecticides - Pesticide Extra Material Handling Screw for loading & Unloading.HP required 2 HP 1440 Electric Motor 2 Nos .

Colloid Mill Machine

85,000 - 150,000 Per 1 Unit

Hammer Mill

150,000 Per Set

Premium pulman export quality hammer mills are multipurpose economy mills that have capability to handle lumpy or uneven size materials to convert course to medium fine powder. The user feeding the material regulates feeding to any required rate. The mill is so intended to offer cooler powdering operation, and therefore indispensable properties of powder such as aroma, flavour, colour, etc. Are held to its most extreme level. Premium pulman is a popular brand amongst top leading manufacturers and exporters of hammer mill in india.

Pug Mill

Get Price Quote

Notable name in this field, we successfully cater to the demands of our clientele from Ahmedabad(India) to every nook and corner. We, along with our veteran packaging professionals, ensure that the packaging products commence keeping the packaging guidelines in consideration. We strictly use quality packaging material to evade loss during transit.

Hammer Mill

53,000 Per Piece

Disintegrator

Get Price Quote

working principal: crushtech, disintegrator are ideally suited where coarse grinding of medium hard and harden minerals, chemicals. The main shaft is the only revolving part, which requires no adjustment. This main shaft runs on rotor plate and it contains swing type hammers. The fineness of the finished products is controlled by the replaceable screens fitted on the lower half of the disintegrator body. The screens of desire mesh can be easily changed. All portions of the body where wear and abrasion is expected are lined with replaceable hard alloy liners. the disintegration is achieved by the impact of hammers against the heavy alloy liner fitted in the body, and the fine products passes through the screen of desired fineness advantage; · used where high impact force is required to break the material. · suitable only for coarse grinding between 10mm to 60 meshes. · hammers and linners of different construction like alloy steel, stainless steel are providing to suit the grinding material. · no rcc foundation is required if fixed on a specially designed avm pad frame · easy and safe operation · less maintenance · its durability, efficiency and economical application: different minerals, coconut shell, ayurvedic products, wood pieces roots and stems, hard rocks etc.

Ball Mill

Get Price Quote

Techno Power engineering is leading manufacturer and exporter of Ball mill in Ahmedabad. Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as beneficiation, construction materials, chemical industry, etc. It has two ore grinding ways: dry way and wet way. According to discharge type of finished powder, it can be divided into two kinds: grid type and overflow type. Ball mill is widely used to process cement, silicate product, new building product, new building materials, fireproof materials, fertilizer, ferrous and non-ferrous metal ore beneficiation, glass, ceramics, etc.

Colloid Mill Machine

100,000 - 150,000 Per Nos.

Silent Features : Coupling provided between motor shaft & rotor shaft for ease in maintenance Three oil seals between the Motor & the processing chamber to prevent liquid going in the motor winding, Resulting in the burning of the motor Modified design of semi concave teeth in rotor & stator reduces the motor HP & gives better performance in size reduction without damaging the product Extended bearing housing specially designed to facilitate fine adjustment of bearing clearances or back lash to avoid metal to metal contact of rotor & stator. This unique design provides smooth & consistence all round performance & long life of rotor & stator Leak proof neoprene sealing device Three way cock system for draining & recirculation of liquids provided as standard. Extra discharge spout provided as standard for viscous products DOL Starter with over load relay for protection against single phasing & low voltage Contact parts can be easily dismantled for cleaning Special design facilitates adjustments of the grinding gap by an exterior screw by means of handle even during operation Flame proof motor & Flame proof rotary switch can be provided on request at extra cost

Ball Mill Grinder Machine

Get Price Quote

We are working with a pool of professionals who are diligent at their work and make sure that the offered lot is packed in high quality material and timely dispatched. Our products are the most sought after in the market, as they are specifically made as per global and domestic quality managements systems. Features: Precision made High strength Industrial application

Ball Mill

Get Price Quote

A good range of batch type ball mills to crush even the hardest materials like, quartz, topaz, ceramics, silica, etc. different types & materials of liners and grinding device is used such as hyper steel, stainless steel, mn Steel, ceramic etc., may be selected to suit the requirement.Application In:Where the dusting is not desired and uniform particle size is must. Such as dyes, minerals, etc.

Colloid Mill Machine

50,000 - 5,000,000 Per Piece

1 Piece (MOQ)

Ball Mill

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Ball Mill to Grind the Material.A good range of batch type ball mills to crush even the hardest materials like, quartz, topaz, ceramics, silica, etc. different types & materials of liners and grinding device is used such as hyper steel, stainless steel, Mn. Steel, ceramic etc., may be selected to suit the requirement.

Ball Mill

Get Price Quote

A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering a 3D printing technology. A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls,flint pebbles and tstainless steel> balls. An internal cascading effect reduces the material to a fine powder. We offer our clients a wide range of Ball mill for Paint, Chemical, Pharma.

Rubber Grinder Mill

Get Price Quote

The grinding characteristic of various materials like resins, gums, waxes hard rubbers, etc. are depend greatly upon their softening temperature. Premium offer the complete system for fiber - Rubber separation system for rubber based industries. We all are well aware that plastics & Rubber these two materials are not completely destroy to the Earth & it only changes the new formation as per industries & societies requirement as new products. In various Rubber Industries waste product is predominantly rubber coated nylon fibres for this we have to literally tear the fibre & shred the same into pieces. There is a certain amount of adhesion of rubber on fibre which has to be weakened. The premium, which leads the sets new standards, has no choice and methods of operation.

Ultra Grinding Mill

Get Price Quote

We ultra febtech - an iso 9001:2008 certified company engaged in manufacturing of ultra grinding mill for industrial grinding machine. Ultra grinding mill is used for size reduction in desired particle size. The ultra grinding mill is screen less. The system consists classifier where the fine particles of desired size are segregated. We have established a note worthy status among the ultra grinding mill manufacturers in india. We bring for the clients ultra grinding mill of exceptional quality at cost-effective price.

Colloid Mill

Get Price Quote

All contact parts are made out of SS 304 (SS 316 on demand at extra charges). No casting are used for avoiding contamination problems. Coupling provided between motor shaft and rotor shaft for ease in maintenance – Vertical Model. Three oil seals between the motor and the processing chamber to prevent liquid going in the motor winding, resulting in the burning of the motor. Modified design of semi concave teeth in rotor and stator reduced motor HP and gives better performance in size reduction without damaging the product. Extended bearing housing specially designed to facilitate fine adjustments of bearing clearances or backlash to avoid metal to metal contact of rotor and stator. This unique design provides smooth and consistence all round performance and long life of rotor and stator.