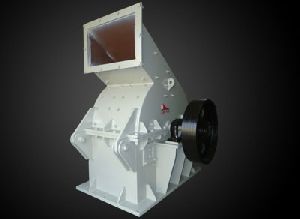

Hammer Mill

50,000 - 300,000 Per Piece

1 Piece(s) (MOQ)

The Hammer Mill, provided by us, is available in most suitable and convenient range to pulverize the material up to 80-100 mesh (150 micron). Our Mill is a robustly constructed machine that is mainly used for crushing different mineral, chemicals, Ayurvedic herbs, Agro Products, etc. Features Of Our Hammer Mill : Use without cyclone and dust collector for bigger output particle size, for fine material cyclone with dust collector is used Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material We offered different types of material for liners and hammer as per client product for better result and best life of wear & tear apart Capacity Range : 100-5000 Kg /hr Our Hammer Mill Is Ideal For : Different chemicals Minerals Pigment Coal Agricultural Products like Gram Maize Rice Husk Sawdust Ayurvedic herbs Cattle Feed Animal Feed Poultry Feed Refractory Ceramics Dolomite Lime stone

Hammer Mill

Get Price Quote

Details The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). Use Hammer Mill without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used. A robustly constructed machine for crushing different mineral, chemical, Ayun/edic Herbs, Agro Products, etc... We offer machine in MS or SS construction with different shape of liner & hammer having metals like MS, En, SS, Mn Steel, Hi-Chrome etc. for better result & best life of wear & tear part. ApplicationDifferent chemical, Minerals Pigment, Coal and Agflcultural Products like Gram Maize Rice-Husk, Sawdust, Ayurvedic Herbs, Cattle Feed, Animal Poultry Feed Reffractory, Ceramics, Dolomite, lime stone etc.

Best Deals from Grinding Mill

Continuous Ball Mill

Get Price Quote

Our company has made its mark as the preeminent Manufacturer, Exporter & Supplier of Continuous Ball Mill from Gujarat, India. Our Continuous Ball Mill is heavily preferred for grinding in various manufacturing industries. We stock the Ball Mill in our spacious warehouse to easily address the bulk requirement of buyers in the shortest period of time. Buyers can obtain the best quality Continuous Ball Mill from us at nominal rates. Model : 500 Later to 2000 Later Direct Gear Drive , Counter Gear for load reduction Contraction : MS + MS / SS Coating + SS + ZeketedIdeal For : VS. Plans

Colloid Mill Machine

50,000 - 5,000,000 Per Piece

1 Piece (MOQ)

disc mill

200,000 Per Set

We are actively engaged in manufacturing and supplying a comprehensive array of disc mill machine. Features: low, medium to high capacity. Two units can be given in one line to increase the output. Comparatively low energy consumption. Complete system i.e. Automatic production. Compact design space saving design. Economical efficient design.

Colloid Mill Machine

100,000 - 150,000 Per Nos.

Silent Features : Coupling provided between motor shaft & rotor shaft for ease in maintenance Three oil seals between the Motor & the processing chamber to prevent liquid going in the motor winding, Resulting in the burning of the motor Modified design of semi concave teeth in rotor & stator reduces the motor HP & gives better performance in size reduction without damaging the product Extended bearing housing specially designed to facilitate fine adjustment of bearing clearances or back lash to avoid metal to metal contact of rotor & stator. This unique design provides smooth & consistence all round performance & long life of rotor & stator Leak proof neoprene sealing device Three way cock system for draining & recirculation of liquids provided as standard. Extra discharge spout provided as standard for viscous products DOL Starter with over load relay for protection against single phasing & low voltage Contact parts can be easily dismantled for cleaning Special design facilitates adjustments of the grinding gap by an exterior screw by means of handle even during operation Flame proof motor & Flame proof rotary switch can be provided on request at extra cost

Colloid Mill Machine

Get Price Quote

Unique for small volume micronization. Modified design of stator-rotor assembly. Totally leak proof design. Easy to dismantle for cleaning and maintenance. Available in plain, water jacketed & flame proof options. Special design colloid mill working principle facilitates adjustment of grinding gap by an exterior screw by means of handle even during operation. Extended bearing housing specially designed to facilitate fine adjustments of bearing clearances or backlash to avoid metal to metal contact of rotor and stator. This unique design provides smooth and consistence all round performance and long life of rotor and stator. Salient Features:- Colloid Mill - Pharmaceutical Milling, Colloid Mill Machine Unique for small volume micronization. Modified design of stator-rotor assembly. Totally leak proof design. Easy to dismantle for cleaning and maintenance. Available in plain, water jacketed & flame proof options. Special design facilitates adjustment of grinding gap by an exterior screw by means of handle even during operation. Extended bearing housing specially designed to facilitate fine adjustments of bearing clearances or backlash to avoid metal to metal contact of rotor and stator. This unique design provides smooth and consistence all round performance and long life of rotor and stator. The colloid mill machine is used as herbal extractor machine, in food processing, and pharmaceutical lab also.

Colloid Mill

Get Price Quote

Ball Mill

Get Price Quote

We are offering ball mill. specification in batch type ball mill is a versatile machine to pulverize even the hardest rocks. In ball mill the material is feed into the shell of mill along with the grinding media. The mill is being run till specific duration so that we can get a desired fineness and then it is being unloaded into empty hopper or any vessel. We use liners, grinding media of different hard material like alloy steel, ceramic, granule brick etc as per hardness of the material. working principal: this machine is a round pattern ball with horizontal cylindrical turning gear, drive by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material. After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding. advantages: � less maintenance, � suitable for both dry or wet grinding and mixing � equal product size � low invest, low energy consumption � easy and safe operation application: quartz, feldspar, paint, ceramic, refractory, calcium carbonate, other minerals & chemicals.

Hammer Mill

Get Price Quote

The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). - A robustly constructed machine for crushing different mineral, chemical, Ayurvedic Herbs, Agro Products, etc... • Capacity Range: 100 - 5000 KG /HR. • Application: Different chemicals, Minerals, Pigment, Coal, and Agricultural Products like Gram, Maize, Rice, Husk, Sawdust, Ayurvedic herbs, Cattle Feed, Animal Feed, Poultry Feed, Refractory, Ceramics, Dolomite, lime stone etc. Features of Hammer Mills 1. Use Hammer Mills without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used.. 2. Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material. 3. Fab-tech Engineers offered different type of material for liners and hammer as per client product for better result and best life of wear & tear part.

Ball Mill

Get Price Quote

Techno Power engineering is leading manufacturer and exporter of Ball mill in Ahmedabad. Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as beneficiation, construction materials, chemical industry, etc. It has two ore grinding ways: dry way and wet way. According to discharge type of finished powder, it can be divided into two kinds: grid type and overflow type. Ball mill is widely used to process cement, silicate product, new building product, new building materials, fireproof materials, fertilizer, ferrous and non-ferrous metal ore beneficiation, glass, ceramics, etc.

Colloid Mill

95,000 - 135,000 Per piece

Colloid Mill

125,000 Per

Ball Mill

Get Price Quote

500 Liter Colloid Mill

95,000 Per Piece

1 Piece (MOQ)

batch ball mill

400,000 Per Piece

Hammer Mill

53,000 Per Piece

Ball Mill

Get Price Quote

A good range of batch type ball mills to crush even the hardest materials like, quartz, topaz, ceramics, silica, etc. different types & materials of liners and grinding device is used such as hyper steel, stainless steel, mn Steel, ceramic etc., may be selected to suit the requirement.Application In:Where the dusting is not desired and uniform particle size is must. Such as dyes, minerals, etc.

Colloid Mill Machine

140,000 - 180,000 Per Nos

10 Piece (MOQ)

Ball Mill

Get Price Quote

We engaged in manufacturing of Ball Mill which are used in heavy duty, continuous type ball milling in that we have three compartment and screen. Replaceable liners are fixed inside entire mill. Liners material and shape is selected based on material to be grind. Input material is fed in two primary grinding compartments. Large diameter balls for reduce particle size are laying inside first compartment. Material comes into second compartment for further grinding. Small size balls are laying inside second compartment. Material comes into third for fine grinding. Smaller size media are laying inside third compartment for fine grinding. Diaphragms may place to regulate material level and control retention time. Material is feed and discharged through hollow trunnion at opposite end. Accessories like air classifier, cyclone, blower, return air circuit or dust collector can also be placed for close loop system. Two tiers fixed on both end of mill, which are rotate on four rollers. Rollers are fixed on support and oil immersed. Mill rotates on four roller and two tiers. Girth gear is fixed on shell, which driven mating gear, gearbox and motor, which are fixed on heavy drive base. continous ball mill jmef continuous ball mill is useful for grinding coarse feed to get fine powder in single continuous operation. It is for grinding ceramics, cement, pencil, paint, chemical, ink, marble, coal, minerals etc. working process: heavy duty, continuous type ball mill with three compartment and screen replaceable liners are fixed inside entire mill liners material and shape is selected based on material to be ground. Material is fed in two primary grinding compartments large diameter balls for reduce particle size lay inside first compartment material comes into second compartment for further grinding small size balls are lying inside second compartment material comes into third for fine grinding

Ball Mill

Get Price Quote

We offer ball mill. A good range of batch type ball mills to crush even the hardest materials like, quartz, topaz, ceramics, silica, etc. Different types & materials of liners and grinding device is used such as hyper steel, stainless steel, mn. Steel, ceramic etc., may be selected to suit the requirement. application in: where the dusting is not desired and uniform particle size is must. Such as dyes, minerals, etc.

Ball Mill Grinder Machine

Get Price Quote

We are working with a pool of professionals who are diligent at their work and make sure that the offered lot is packed in high quality material and timely dispatched. Our products are the most sought after in the market, as they are specifically made as per global and domestic quality managements systems. Features: Precision made High strength Industrial application

Pug Mill

Get Price Quote

Notable name in this field, we successfully cater to the demands of our clientele from Ahmedabad(India) to every nook and corner. We, along with our veteran packaging professionals, ensure that the packaging products commence keeping the packaging guidelines in consideration. We strictly use quality packaging material to evade loss during transit.

Hammer Mill

100,000 Per Pieces

1 Piece (MOQ)

Ball Mill

950,000 - 1,000,000 Per Piece

Grain Hammer Mill

Get Price Quote

15 Models (Upto 200 HP) * Ideal For Precrushing & Coarse Grinding * 50 To 25,000 KgsHr.Cap. * Cool Grinding * Low Power Consumption * 3 in 1 Unit (pulverizing, Sieving & Conveying) * Available with Negative Pressure System also. * Wet milling also available. * Grinding element in different shape to application. * Bottom Discharge Also * Side Screen Opening Also * With Star Type Hammer * M.O.C. In MSSS

Colloid

Get Price Quote

Clit Colloid Mill is suitable for Homogenizing, Emulsifying, Dispersing, Mixing, Comminuting of liquids to highly viscous products. It is based on rotor-stator principle. It is available in plan as well as Water Jacketed model which is suitable for heat sensitive products. Flame Proof electrical can be supplied on demands.

Colloid Mill

Get Price Quote

*Depending upon material characteristics viscosity, density & micron size. R&D Model Available on Customer Demand. Totally leak proof design. Unique for small volume micronization. Modified design of stator-rotor assembly. Available in plain, water jacketed & flame proof options. Easy to dismantle for cleaning and maintenance

Ball Mill

Get Price Quote

A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering a 3D printing technology. A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls,flint pebbles and tstainless steel> balls. An internal cascading effect reduces the material to a fine powder. We offer our clients a wide range of Ball mill for Paint, Chemical, Pharma.

Batch Type Ball Mill

Get Price Quote

We present special Batch Type Ball Mills to our clients. These Batch Type Ball Mills are known for the unique design and advanced technology that makes these Batch Type Ball Mills an efficient machine to work with. We manufacture these Batch Type Ball Mills with the best quality components for the desired performance and durability. Attributes : A versatile machine to pulverize even the hardest rocksGrinding and Liners made up of different hard material like Ceramic, Alloy steel, Granule brick etc available Suitable for : wet and dry grinding and mixing Application : CeramicQuartzPaintFeldspar Technical Specifications Model Volume in Ltrs. Cylinder Dimension *Production in Kg. / Hr. Dia. in mm.Length in mm.BMP-1001006406002 - 3BMP-2502506008003 - 5BMP-50050080010003 - 7.5BMP-75075085012505 - 10BMP-10001000100012507.5 - 15BMP-150015001250125010 - 20BMP-220022001250180015 - 30BMP-350035001500200025 - 50BMP-500050001800200030 - 60BMP-640064001800250040 -75BMP-11000110002400250050 - 100