Ball Mill

Get Price Quote

We offer ball mill. A good range of batch type ball mills to crush even the hardest materials like, quartz, topaz, ceramics, silica, etc. Different types & materials of liners and grinding device is used such as hyper steel, stainless steel, mn. Steel, ceramic etc., may be selected to suit the requirement. application in: where the dusting is not desired and uniform particle size is must. Such as dyes, minerals, etc.

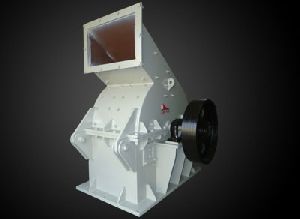

Hammer Mill

53,000 Per Piece

Best Deals from Grinding Mill

Ball Mill

Get Price Quote

A good range of batch type ball mills to crush even the hardest materials like, quartz, topaz, ceramics, silica, etc. different types & materials of liners and grinding device is used such as hyper steel, stainless steel, mn Steel, ceramic etc., may be selected to suit the requirement.Application In:Where the dusting is not desired and uniform particle size is must. Such as dyes, minerals, etc.

batch ball mill

Get Price Quote

We are offering Batch Ball Mill to our esteemed customers across the world. Our Ball Mill is designed by our skilled professionals who conform to the latest safety parameters for its production. We are a renowned Manufacturer, Exporter & Supplier of Batch Ball Mill from Gujarat, India and known for our fair pricing policy. Details: Batch ball mill (Ceramic ball mill) is mainly used for mixing, milling of the materials. It works with less energy but produces high fineness product. It has two types, wet mills and dry mills. The machine could use different lining board according to product requirement to satisfy different customer’s requirement. The milling fineness depends on the milling time. The motor is started by the coupling which can reduce voltage and lower the starting electricity. The structure is divided into integral type and freestanding type. Advantages of the machine are lower investment, energy saving, structure novelty, easy and safe to operate, stable and reliable performance, etc. It is suitable for mixing and milling of general and special materials. Users can choose the proper model, lining board and media as per the factors, such as material’s specific gravity and hardness, as well as output, etc.

Pellet Press

Get Price Quote

Pellet press The DIE – RING and ROLLER made out of ALLOY steel and are hardened.Die-head have tapered radial valve to facilitate PELLETE forming of desired diameters. Can be provided with FEEDER- CONDITIONER.

Colloid Mill

Get Price Quote

Colloid Mill

Get Price Quote

colloid mill is used for reducing size of solid particles suspended in a liquid. It acts as a good homogenizer and emulsifier in a solution. Colloid mill is also used in reducing the droplet size of a liquid that may be suspended in another liquid. The equipment is specially manufactured in a conical arrangement to achieve the required centrifugal force that maximizes the milling effect. The feeding system is efficient and the machine subjects the product to high forces of shearing, cutting and rubbing forces to create a homogenous mixture.

Grinding Ball Mill

Get Price Quote

Colloid Mill Machine

140,000 - 180,000 Per Nos

10 Piece (MOQ)

Colloid Mill Machine

85,000 - 150,000 Per

Ball Mill Grinder Machine

Get Price Quote

We are working with a pool of professionals who are diligent at their work and make sure that the offered lot is packed in high quality material and timely dispatched. Our products are the most sought after in the market, as they are specifically made as per global and domestic quality managements systems. Features: Precision made High strength Industrial application

Ball Mill

Get Price Quote

Techno Power engineering is leading manufacturer and exporter of Ball mill in Ahmedabad. Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as beneficiation, construction materials, chemical industry, etc. It has two ore grinding ways: dry way and wet way. According to discharge type of finished powder, it can be divided into two kinds: grid type and overflow type. Ball mill is widely used to process cement, silicate product, new building product, new building materials, fireproof materials, fertilizer, ferrous and non-ferrous metal ore beneficiation, glass, ceramics, etc.

Pug Mill

Get Price Quote

Notable name in this field, we successfully cater to the demands of our clientele from Ahmedabad(India) to every nook and corner. We, along with our veteran packaging professionals, ensure that the packaging products commence keeping the packaging guidelines in consideration. We strictly use quality packaging material to evade loss during transit.

batch ball mill

400,000 Per Piece

700 Liter Colloid Mill

95,000 Per Piece

1 Piece (MOQ)

Hammer Mill

Get Price Quote

The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). - A robustly constructed machine for crushing different mineral, chemical, Ayurvedic Herbs, Agro Products, etc... • Capacity Range: 100 - 5000 KG /HR. • Application: Different chemicals, Minerals, Pigment, Coal, and Agricultural Products like Gram, Maize, Rice, Husk, Sawdust, Ayurvedic herbs, Cattle Feed, Animal Feed, Poultry Feed, Refractory, Ceramics, Dolomite, lime stone etc. Features of Hammer Mills 1. Use Hammer Mills without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used.. 2. Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material. 3. Fab-tech Engineers offered different type of material for liners and hammer as per client product for better result and best life of wear & tear part.

Ultra Grinding Mill

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Air Classifier Mill to Industrial Grinding Equipment Machinery. Air Classifier Mill is used for size reduction in desired particle size. The air classifying mill is screen less. The system consists classifier where the fine particles of desired size are segregated. We have established a note worthy status among the Ultra Air Classifying Mill Manufacturers in India. We bring for the clients Air Classifying Mill of exceptional quality at cost-effective price.

Lab Colloid Mill

Get Price Quote

The Laboratory scale colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size of a liquid suspended in another liquid. This is done by applying high levels of hydraulic shear to the process liquid. It is frequently used to increase the stability of suspensions and emulsions. The colloid mill is used for various applications such as Superfine grinding, homogenizing, emulsifying, dispersing, mixing and extracting of liquids, ointments and highly viscous products in pharmaceutical, cosmetics, suspensions & emulsion industry. The product is fed to the hopper which leads the product into the gap between rotor and stator. The product is subjected to a high degree of shearing, cutting and rubbing between two metal toothed surfaces of rotor and stator and towards the discharge section. The processed product continuously leaves the mill through drain pipe if required, it can be re-circulated by three way cock and re-circulating pipe assembly. New Design Features: Laboratory scale colloid mill is used for Homogenizing, Emulsifying, Dispersing, Mixing, Comminuting of Ointment, Liquid and highly viscous products research and development institutions, pharmaceutical laboratory, and pharmacy colleges. All contact parts are in S.S.316 non contact parts in S.S.304 Quality. Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Easy to adjustment gap between rotor and stator. Three way cock assembly with re-circulating pipe. Silicon food grade seal. Separate discharge spout for highly viscous products. Optional: Horizontal or vertical drive model, water cooling systems, Explosion proof electrical.

Plastic Grinding Mills

Get Price Quote

The material in granular form is fed from a feeding hopper to the Pulveriser. The material is Pulverised between two serrated discs & then air conveyed to a Screening equipment. The coarse material is recycled to the Pulveriser for further size reduction. The fine (desired) Powder can be filled in bags or containers. Grinding by shear. Cool grinding Chamber Because of large Airflow due to design of mill & Blower.Grinding gap between the two grinding discs can be adjusted from the outside of the machine. This Disc Mill does not have any Screen so no problem of chocking & excess heat generation. The Body of the mill is water jacketed & fabricated out of heavy mild steel. We used graded material EN-41-B for disc mill & main shaft made of EN - 8. dynamically balanced for smooth operation. This system provides noise less operation and trouble free working and mode from EN-8 material. Several options are available to simplify the cleaning process. The front door with the grinding disc can be opened easily, thus making the grinding chamber accessible for easy & fast clearing. Suitable Structural platform is supplied for Ease of operation. Necessary spare parts also ready available at our factory.

Ball Mill

950,000 - 1,000,000 Per Piece