Tarpaulin Sheets

Extrusion Lamination Plants have been developed for LDPE PP Extruded film Lamination on Woven Sacks Knitted Bags, Woven Fabrics, BOPP, Paper, Aluminium Foil, Pre-Printed BOPP, Non Wovens, Jute, Tarpaulins, Geo Textiles & many other applications...

...more

Tarpaulin Manufacturing Machines

For Manufacturing Laminated Tarpaulins Geo-Textiles, Non-Wovens & Jute. Range and Capacity :- From 100Kgs/hr to 900kgs/hr. for PP/HDPE. Salient Features :- First in india to launch fully inverter duty Tape Stretching Plants along with inverter duty winders. Extrusion Plants with low process variations in terms of Denier, GSM & Film Thickness in Microns. Extrusion Plants with negligible maintenance costs as machines are manufactured with world standard components. Extrusion Plants with lowerst energy consumption in their class with options of centralised computer control & are most economical to run. Extrusion Lamination Plants Extrusion Lamination Plants have been developed for LDPE / PP Extruded film Lamination on Woven Sacks / Knitted Bags, Woven Fabrics, BOPP, Paper, Aluminium Foil, Pre-Printed BOPP, Non Wovens, Jute, Tarpaulins, Geo Textiles & many other applications... Range and Capacity :- From 1000mm width upto 6000mm Width Having Capacity starting from 100kgs/hr upto 900kgs/hr and line speed of more than 200mtr/min Salient Features :- Extrusion Lamination and Coating Plants with High Speed High Production upto 200mts/min for Flat and Clircular Woven Fabrics. Sandwitch Lamination of printed BOPP. Polyster, Paper, Jute, Non-Wovens, Cotton Fabrics, Woven Sacks, Fabrics, Aluminium Foils and Tarpaulins. Our Highest Selling, Proven and Versatile High Speed High Production Extrusion Lamination plants for Laminating, Woven Sacks, Jumbo Bags and FIBC Fabrics, sandwitch lamination of BOPP/Polyster , CPP, Paper and Aliminium foils, now available with MIXTRUDE ™Technology

...more

tarpaulin making machine

First in india to launch fully inverter duty Tape Stretching Plants along with inverter duty winders. Extrusion Plants with low process variations in terms of Denier, GSM & Film Thickness in Microns. Extrusion Plants with negligible maintenance costs as machines are manufactured with world standard components. Extrusion Plants with lowerst energy consumption in their class with options of centralised computer control & are most economical to run.

...more

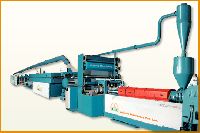

tape stretching line

Extrusion Tape Stretching Plant have been developed for producing PP HDPE tapes for many applications such as Woven Sacks Knitted Bags Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications...

...more

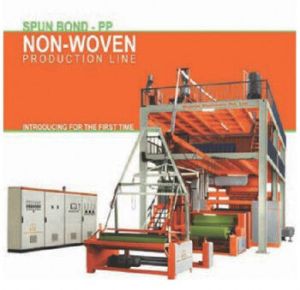

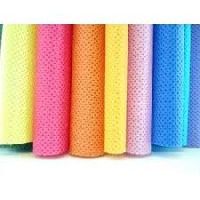

Spunbond Pp Nonwoven Fabric

the polypropylene (pp) spun-bond non-woven fabric composite manufacturing equipment has been developed after years of practice and production operations, which makes the design and operation more user friendly. At the same time, incorporation of foreign advanced technology & specifications lead to superior performance, net uniform & beautiful color, resulting in excellent product quality. the production process can also add renewable raw materials and filler materials to reduce product costs. types & specifications : s, ss, sms, smms customized pp non-woven fabric production lines are available. available working width range : 1600mm, 2400mm, 3200mm, 4500mm and special sizes. (s stands for spun-bonded & m stands for melt-blown) main specifications : width: 1.6m, 2.4m, 3.2m & 4.5m ( special sizes available on request) max winding diameter: 1200mm. productivity: 70g/square meter, 6t---7t/24 hours. monofilament fiber denier range ( overall ) ; 1-4 den main material: pp chips or pp powder along with color additives & filler material. grammage overall : 10-250gsm mechanical speed : 10-150m/min. electricity consumption : 800-1400kwh/t material wastage consumption rate : 0.5% product quality standard: confirms to our national standards. salient features : advanced technologies from overseas and the domestic production experience of our company has been used in developing these non-woven fabric production lines. The line's advantage is lower capital investment, compact construction, smaller working area, easy production technology and operations with less labor and wide compatibility. These lines produce polypropylene (pp) non-woven fabric by negative wind pressure to make the pp spun-bonded non-woven fabric with excellent even layflat width, excellent tensile strength, better ventilation and better soft feelings. It has been in wide application for medical supplies, hygiene, packaging industry, agriculture and so on..... the plc / computer control system incorporated in the non-woven fabric production lines are simple & easy to use for making the technical adjustments more easier and reliable and the lines are suitable for different raw materials to give more versatility in usage. simple space requirements for the non-woven fabric production lines, greatly reduce the real estate investment and enlarge the utilization of the workshop. specialized processing equipment incorporated in the non-woven fabric production lines improve the machine's accuracy and performance, reduce manufacturing costs, thereby, making excellent finish products with economical advantage. pp spun-bond non-woven fabric usage : medical supplies & hygiene :wound care bandage & gauze, hospital gowns & patient drapes, face masks, protective apparel, baby diapers & training pants, adult incontinence pads, underwear, femcare napkins, panty liners, sanitary napkins and tampons.packing and industry :shopping bags, tarpaulins, tents, bags for rice / sugar, luggage internal liners, vacuum cleaner bag, buff pad, interlining and cloth, shoulder padding, packing & coverings, beach umbrellas etc.argriculture :cover for trees & plantations, garden covers etc, etc.

Material : Non Woven

...more

Sheet Extrusion Plant

Plastic Sheet Extrusion Plant are developed for manufacturing Plastic Sheets of Various Sizes Width & thickness from PP, HDPE, PET & PVC... All our Models are available with options of Double Layer Model "IDSP-DL" and Three Layer Model IDSP-TL also.

...more

Sack Making Machine

First in india to launch fully inverter duty Tape Stretching Plants along with inverter duty winders. Extrusion Plants with low process variations in terms of Denier, GSM & Film Thickness in Microns. Extrusion Plants with negligible maintenance costs as machines are manufactured with world standard components. Extrusion Plants with lowerst energy consumption in their class with options of centralised computer control & are most economical to run.

...more

Pre Printed BOPP Film Sandwich Extrusion Lamination Machine

1 Piece(s) (MOQ)

extrusion lamination plants have been developed for ldpe / pp extruded film lamination on woven sacks / knitted bags, woven fabrics, bopp, paper, aluminium foil, pre-printed bopp film sandwich lamination, non wovens, jute, tarpaulins, geo textiles & many other applications. range and capacity :- from 1000mm width upto 6000mm width having capacity starting from 100kgs/hr upto 900kgs/hr and line speed of more than 200mtr/min models:- lamistar tm satra 100 lamistar tm tera 50 lamistar tm ek 1000 lamistar tm bais 100 salient features :- extrusion lamination and coating plants with high speed high production upto 200mts/min for flat and clircular woven fabrics. Sandwitch lamination of printed bopp. Polyster, paper, jute, non-wovens, cotton fabrics, woven sacks, fabrics, aluminium foils and tarpaulins. our highest selling, proven and versatile high speed high production extrusion lamination plants for laminating, woven sacks, jumbo bags and fibc fabrics, sandwitch lamination of bopp/polyster , cpp, paper and aliminium foils, now available with mixtrude ™technology

Type : Extrusion Coating Lamination Machine

Application : Coating Lamination

Voltage : 440V

Condition : New

Automatic Grade : Automatic, Manual, Semi Automatic

Driven Type : Electric, Pneumatic

Brand Name : LAMISTAR tm TANDEM tm

Application : EXTRUSION LAMINATION

...more

PP Woven Sack Manufacturing Machines

Extrusion Tape Stretching Plant have been developed for producing PP / HDPE tapes for many applications such as Woven Sacks / Knitted Bags / Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications. Range and Capacity :- From 100Kgs/hr to 900kgs/hr. for PP/HDPE. Models:- IDTP - HS-900-D-1600IDTP - HS-600-D-1600IDTP - HS-450-D-1500IDTP - 450-D-1500IDTP - 350-D-1400IDTP - 350-D-1250IDTP - 250-D-1250IDTP - 250-D-1100IDTP - 150-D-1000IDTP - 150-D-800IDTP - 100-D-650 Salient Features :- First in india to launch fully inverter duty Tape Stretching Plants along with inverter duty winders. Extrusion Plants with low process variations in terms of Denier, GSM & Film Thickness in Microns. Extrusion Plants with negligible maintenance costs as machines are manufactured with world standard components. Extrusion Plants with lowerst energy consumption in their class with options of centralised computer control & are most economical to run.

...more

Pp Woven Jumbo Bag

Extrusion Tape Stretching Plant have been developed for producing PP HDPE tapes for many applications such as Woven Sacks Knitted Bags Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications...

...more

PP nonwoven fabric

The Polypropylene (PP) Spun-Bond Non-Woven Fabric composite manufacturing equipment has been developed after years of practice and production operations, which makes the design and operation more user friendly. At the same time, incorporation of foreign advanced technology & specifications lead to superior performance, net uniform & beautiful color, resulting in Excellent Product Quality. The production process can also add renewable raw materials and filler materials to reduce product costs.

Width : 1.6m, 2.4m, 3.2m & 4.5m

...more

Pp Non Woven Fabrics

The Polypropylene (PP) Spun-Bond Non-Woven Fabric composite manufacturing equipment has been developed after years of practice and production operations, which makes the design and operation more user friendly. At the same time, incorporation of foreign advanced technology & specifications lead to superior performance, net uniform & beautiful color, resulting in Excellent Product Quality. The production process can also add renewable raw materials and filler materials to reduce product costs.

...more

polypropylene spunbond non woven fabric

The Polypropylene (PP) Spun-Bond Non-Woven Fabric composite manufacturing equipment has been developed after years of practice and production operations, which makes the design and operation more user friendly. At the same time, incorporation of foreign advanced technology & specifications lead to superior performance, net uniform & beautiful color, resulting in Excellent Product Quality.

...more

Plastic Waste Recycling Machine

2,800,000 - 9,000,000 Per Unit

Voltage : 440 Volt

plastic sheet extrusion plant

Plastic Sheet Extrusion Machine

Plastic Sheet Extrusion Plant are developed for manufacturing Plastic Sheets of Various Sizes Width & thickness from PP, HDPE, PET & PVC... Inverter Duty Extrusion Sheet Plants from 100kgs hr upto 900kgs hr production capacity from 0.3mm thickness upto 20mm thickness, width 530mm upto 1500mm, for the PP HIPS Thermoformed Disposable Container and Sheet manufacturing industry for PP, HDPE, PET & PVC.

...more

non woven textile machinery

The Polypropylene (PP) Spun-Bond Non-Woven Fabric composite manufacturing equipment has been developed after years of practice and production operations, which makes the design and operation more user friendly. At the same time, incorporation of foreign advanced technology & specifications lead to superior performance, net uniform & beautiful color, resulting in Excellent Product Quality.

...more

Jumbo Bag Making Machine

Extrusion Tape Stretching Plant have been developed for producing PP HDPE tapes for many applications such as Woven Sacks Knitted Bags Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Tarpaulins , Wrapping fabrics & many other applications.

...more

Hdpe Woven Sacks

Extrusion Tape Stretching Plant have been developed for producing PP HDPE tapes for many applications such as Woven Sacks Knitted Bags Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications...

...more

HDPE Woven Sack Manufacturing Plants

Extrusion Tape Stretching Plant have been developed for producing PP / HDPE tapes for many applications such as Woven Sacks / Knitted Bags / Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications. Range and Capacity :- From 100Kgs/hr to 900kgs/hr. for PP/HDPE. Models:- IDTP - HS-900-D-1600IDTP - HS-600-D-1600IDTP - HS-450-D-1500IDTP - 450-D-1500IDTP - 350-D-1400IDTP - 350-D-1250IDTP - 250-D-1250IDTP - 250-D-1100IDTP - 150-D-1000IDTP - 150-D-800IDTP - 100-D-650 Salient Features :- First in india to launch fully inverter duty Tape Stretching Plants along with inverter duty winders. Extrusion Plants with low process variations in terms of Denier, GSM & Film Thickness in Microns. Extrusion Plants with negligible maintenance costs as machines are manufactured with world standard components. Extrusion Plants with lowerst energy consumption in their class with options of centralised computer control & are most economical to run.

...more

HDPE Sacks

Extrusion Tape Stretching Plant have been developed for producing PP HDPE tapes for many applications such as Woven Sacks Knitted Bags Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications...

...more

PP / HDPE Flat Tape Weaving Circular Looms

500,000 Per Piece

10 Piece(s) (MOQ)

home » products » pp/hdpe flat tape weaving circular looms pp/hdpe flat tape weaving circular looms eight shuttle circular looms six shuttle circular looms four shuttle circular looms shuttles infeed arrangement weft break detection system grommet band with heddle wire weft end detection system salient features of the circular looms : we have adopted a flat cam structure with high output, high efficiency, lower electrical consumption & low maintenance. we have incorporated the idler wheel form of shuttle requiring no lubrication, hence, it is environment friendly. automatic warp tension control system is provided for manufacturing better quality of fabric. man machine interface is provided with micro processor to control the loom functions with ease of operations. these machines can be used for manufacture of general pp / hdpe woven sacks fabrics, fibc/ jumbo bag fabrics, tarpaulin fabrics, etc, etc…. .

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

...more

epe foam sheet production line

machine unit size of thickening roller : 192mm×1600mm material of thickening roller : steel. open and close method of thickening roller : motorized up and down of two rolls. drive power : 1.1kw x 3 driving method : gear box driven by motor, direct transmission, easy operation, safety and beauty. heating method : electric heating heating box one set : composed of 10 heaters heating power : 3.5kw x 10 pcs air engine power : 1.5kw needle roller : 100mm x 1600mm haul-off roller : 100mm x 1600mm haul-off material : rubber open and close method : driven by cylinder. winding method : torque motor control winding motor torque : 16nm controlling unit electric control cabinet for temperature control : high accuracy pid controller, guarantees the working temperature control accuracy. heating zone : 8 nos. heating control method : silicon controlled voltage regulator controls the voltage of both sides of the heater to change the heating temperature. motor control : ac inverter drives with synchronization for controlling all the three motors, they are, two thickening roller motors and one haul off roller motor, so that, it can adjust and choose the rotating speed as needed by the working conditions. other features : equipped with length-meter counter & alert-buzzer system. Length can be freely set as needed. After reaching the set length, the meter counter will give signal.

Type : Epe Foam Sheet Extrusion Line

Application : Making Epe Foam Sheet

Certification : ISO 9001:2008

Voltage : 440V

Condition : New

Automatic Grade : Automatic, Semi Automatic

Driven Type : Electric, Mechanical

Warranty : 1year

Brand Name : GUJARAT MACHINERY PVT LTD

Application : MANUFACTURE OF EPE FOAM SHEET

Type : EXTRUSION MACHINE / PLANT / LINE

Processing Type : PE POLYMER PLASTIC EXTRUSION

...more

Gearless Tape Stretching Lines

FIRST IN INDIA TO LAUNCH THE DIRECT TORQUE TAPE STRETCHING LINES ALONG WITH INVERTER DUTY WINDERS THESE EXTRUDERS SAVE ENERGY BY UP TO 15-20% BY EMPLOYING THE WORLD RENOWNED DIRECT TORQUE MECHANISM, WHEREIN, THE ENERGY LOSSES ARISING DUE TO THE INCORPORATION OF THE HELICAL GEARBOX IN EXTRUDER DESIGN IS COMPLETELY REMOVED. THAT MEANS, IN THESE EXTRUDERS - THE HELICAL GEARBOX IS COMPLETELY REMOVED! EXTRUSION LINES WITH LOW PROCESS VARIATIONS IN TERMS OF DENIER, GSM & FILM THICKNESS IN MICRONS. OPTION OF GERMAN MELT PUMPS FOR EXTRUDERS, IMPORTED DIES, AUTO-FILM GAUGE CONTROL & MONITORING SYSTEMS ARE ALSO PROVIDED. EXTRUSION LINES WITH NEGLIGIBLE MAINTENANCE COSTS AS MACHINES ARE MANUFACTURED WITH WORLD STANDARD COMPONENTS. FULLY INVERTER DUTY EXTRUSION LINES WITH LOWEST ENERGY CONSUMPTION IN THEIR CLASS, WITH OPTIONS OF CENTRALISED COMPUTER / PLC CONTROLS, WHICH ARE MOST ECONOMICAL DURING RUNNING OPERATIONS.

...moreBe first to Rate

Rate ThisOpening Hours