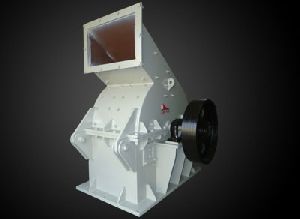

Hammer Mill

50,000 - 300,000 Per Piece

1 Piece(s) (MOQ)

The Hammer Mill, provided by us, is available in most suitable and convenient range to pulverize the material up to 80-100 mesh (150 micron). Our Mill is a robustly constructed machine that is mainly used for crushing different mineral, chemicals, Ayurvedic herbs, Agro Products, etc. Features Of Our Hammer Mill : Use without cyclone and dust collector for bigger output particle size, for fine material cyclone with dust collector is used Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material We offered different types of material for liners and hammer as per client product for better result and best life of wear & tear apart Capacity Range : 100-5000 Kg /hr Our Hammer Mill Is Ideal For : Different chemicals Minerals Pigment Coal Agricultural Products like Gram Maize Rice Husk Sawdust Ayurvedic herbs Cattle Feed Animal Feed Poultry Feed Refractory Ceramics Dolomite Lime stone

Hammer Mill

Get Price Quote

Details The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). Use Hammer Mill without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used. A robustly constructed machine for crushing different mineral, chemical, Ayun/edic Herbs, Agro Products, etc... We offer machine in MS or SS construction with different shape of liner & hammer having metals like MS, En, SS, Mn Steel, Hi-Chrome etc. for better result & best life of wear & tear part. ApplicationDifferent chemical, Minerals Pigment, Coal and Agflcultural Products like Gram Maize Rice-Husk, Sawdust, Ayurvedic Herbs, Cattle Feed, Animal Poultry Feed Reffractory, Ceramics, Dolomite, lime stone etc.

Best Deals from Hammer Mill

Hammer Mill

Get Price Quote

We are offering hammermill. hammer machine crushes the material from fine to course in bulk, these machines can be provided with cyclone, dust collector for avoiding pollution, easy collection at discharge end & avoid wastage of materials. The grinding chamber of hammer mill is lined with heavy steel liners, which protects the body from wear and tear. A balanced rotor in hammer mill with a set of swing hammers accelerates the grinding process. working principle: material is feed into the hammer mill from the top and falls into the grinding chamber. The material is contacted by a series of hardened steel hammers rotating at high speed. The material is ground by repeated contact with these hammers, contact with the walls of the grinding chamber, and particle to particle contact. The material remains in the hammer mill grinding chamber until particles become small enough to pass through the perforated screen that covers the bottom half of the grinding chamber.

Hammer Mill

Get Price Quote

The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). - A robustly constructed machine for crushing different mineral, chemical, Ayurvedic Herbs, Agro Products, etc... • Capacity Range: 100 - 5000 KG /HR. • Application: Different chemicals, Minerals, Pigment, Coal, and Agricultural Products like Gram, Maize, Rice, Husk, Sawdust, Ayurvedic herbs, Cattle Feed, Animal Feed, Poultry Feed, Refractory, Ceramics, Dolomite, lime stone etc. Features of Hammer Mills 1. Use Hammer Mills without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used.. 2. Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material. 3. Fab-tech Engineers offered different type of material for liners and hammer as per client product for better result and best life of wear & tear part.

Hammer Mill

53,000 Per Piece

Hammer Mill

150,000 Per Set

Premium pulman export quality hammer mills are multipurpose economy mills that have capability to handle lumpy or uneven size materials to convert course to medium fine powder. The user feeding the material regulates feeding to any required rate. The mill is so intended to offer cooler powdering operation, and therefore indispensable properties of powder such as aroma, flavour, colour, etc. Are held to its most extreme level. Premium pulman is a popular brand amongst top leading manufacturers and exporters of hammer mill in india.

Hammer Mill

Get Price Quote

We manufacture, export and supply high quality Hammermill that are known for durability and efficiency. These Mill Manufacturer are made with the use of best quality components and are available at economic prices. Functioning :The material is moved to the Hammer Mill once it is out from the second hopper. The principle involved is that materials get crushed with the impact of the swinging hammers. The material reaches out to the grinding chamber after it is fed from the top of the Hammer Mill. Rotating hammers made up of manganese come in contact with the material which is then crushed to the desired extent and then are made to pass through the perforated screen. Then the material is sent to the screw conveyer and is transported to second bucket for storage silo. Attributes : Robust construction Efficient High performance Low maintenance Used for : Grinding different types of free flowing materials

Maize Grinding Hammer Mill

Get Price Quote

Grain Hammer Mill

Get Price Quote

15 Models (Upto 200 HP) * Ideal For Precrushing & Coarse Grinding * 50 To 25,000 KgsHr.Cap. * Cool Grinding * Low Power Consumption * 3 in 1 Unit (pulverizing, Sieving & Conveying) * Available with Negative Pressure System also. * Wet milling also available. * Grinding element in different shape to application. * Bottom Discharge Also * Side Screen Opening Also * With Star Type Hammer * M.O.C. In MSSS

Hammer Mill

100,000 Per Pieces

1 Piece (MOQ)

Hammer Mill

Get Price Quote

Ultra Febtech Pvt. Ltd. make a Hammer mill which is used for the materials that are grounded on the impact of the hammer. The feed is at the top and while rotating in the grinding shell; it is often allied beaten by the swing type hammers fixed to the rotor. It is crushed by frequent contact of hammers and wall. A screen is round the rotor, which prevents the bigger particles to escape from the chamber. The mill is made in SS and MS.

Super Hammer Mill

75,000 Per unit

Hammer Mill

Get Price Quote

Copper Plated Cylinders, Ready To Engrave Cylinders

Grinding Hammer Mills

Get Price Quote

Grinding Hammer Mills, Ice Crushing Machines, Cashew Dryer, Hammer Mills

Hammer Mill

Get Price Quote

Ultra Fine Grinder, size reduction machinery, guar gum plant, Nauta Mixer

Hammer Mill

Get Price Quote

Fabricated Equipments, hammer mill parts, Horizontal Ribbon Blender