Hammer Mill

Get Price Quote

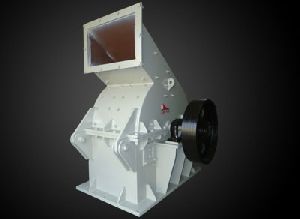

Details The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). Use Hammer Mill without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used. A robustly constructed machine for crushing different mineral, chemical, Ayun/edic Herbs, Agro Products, etc... We offer machine in MS or SS construction with different shape of liner & hammer having metals like MS, En, SS, Mn Steel, Hi-Chrome etc. for better result & best life of wear & tear part. ApplicationDifferent chemical, Minerals Pigment, Coal and Agflcultural Products like Gram Maize Rice-Husk, Sawdust, Ayurvedic Herbs, Cattle Feed, Animal Poultry Feed Reffractory, Ceramics, Dolomite, lime stone etc.

Hammer Mill

50,000 - 300,000 Per Piece

1 Piece(s) (MOQ)

The Hammer Mill, provided by us, is available in most suitable and convenient range to pulverize the material up to 80-100 mesh (150 micron). Our Mill is a robustly constructed machine that is mainly used for crushing different mineral, chemicals, Ayurvedic herbs, Agro Products, etc. Features Of Our Hammer Mill : Use without cyclone and dust collector for bigger output particle size, for fine material cyclone with dust collector is used Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material We offered different types of material for liners and hammer as per client product for better result and best life of wear & tear apart Capacity Range : 100-5000 Kg /hr Our Hammer Mill Is Ideal For : Different chemicals Minerals Pigment Coal Agricultural Products like Gram Maize Rice Husk Sawdust Ayurvedic herbs Cattle Feed Animal Feed Poultry Feed Refractory Ceramics Dolomite Lime stone

Best Deals from Hammer Mill

Hammer Mill

130,000 - 420,000 Per comp

We have carved a niche for ourselves as a Manufacturer, Exporter, and Supplier of Hammer Mill. The Masala Hammer Crushing Mill has been extensively used in the crushing and shredding of various materials, which results in smaller pieces. The optimized hammer design of the Hammer Mill can provide precise and consistent grinding as well as easy access. The Hammer Mill is competitively priced as well as timely and safely delivered.

Hammer Mill

53,000 Per Piece

Hammer Mill

Get Price Quote

Use for all Application, Grinding grains, Spices, Chemicals, Rocks, Salt, etc...

Hammer Mill

40,000 Per

3 Meter (MOQ)

APPLICATION :- Iron ore Coal & fly ash Aggregates Sand & gravel Pulp & paper Agricultural Chemical Food processing Process plant & allied industries Powder Transport Construction industry Manufacturing industry Heavy duty industry

Hammer Mill

150,000 Per Set

Premium pulman export quality hammer mills are multipurpose economy mills that have capability to handle lumpy or uneven size materials to convert course to medium fine powder. The user feeding the material regulates feeding to any required rate. The mill is so intended to offer cooler powdering operation, and therefore indispensable properties of powder such as aroma, flavour, colour, etc. Are held to its most extreme level. Premium pulman is a popular brand amongst top leading manufacturers and exporters of hammer mill in india.

Hammer Mill

Get Price Quote

The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). - A robustly constructed machine for crushing different mineral, chemical, Ayurvedic Herbs, Agro Products, etc... • Capacity Range: 100 - 5000 KG /HR. • Application: Different chemicals, Minerals, Pigment, Coal, and Agricultural Products like Gram, Maize, Rice, Husk, Sawdust, Ayurvedic herbs, Cattle Feed, Animal Feed, Poultry Feed, Refractory, Ceramics, Dolomite, lime stone etc. Features of Hammer Mills 1. Use Hammer Mills without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used.. 2. Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material. 3. Fab-tech Engineers offered different type of material for liners and hammer as per client product for better result and best life of wear & tear part.

Hammer Mill

Get Price Quote

We are offering hammermill. hammer machine crushes the material from fine to course in bulk, these machines can be provided with cyclone, dust collector for avoiding pollution, easy collection at discharge end & avoid wastage of materials. The grinding chamber of hammer mill is lined with heavy steel liners, which protects the body from wear and tear. A balanced rotor in hammer mill with a set of swing hammers accelerates the grinding process. working principle: material is feed into the hammer mill from the top and falls into the grinding chamber. The material is contacted by a series of hardened steel hammers rotating at high speed. The material is ground by repeated contact with these hammers, contact with the walls of the grinding chamber, and particle to particle contact. The material remains in the hammer mill grinding chamber until particles become small enough to pass through the perforated screen that covers the bottom half of the grinding chamber.

Hammer Mill

100,000 Per Pieces

1 Piece (MOQ)

Hammer Mill

Get Price Quote

We manufacture, export and supply high quality Hammermill that are known for durability and efficiency. These Mill Manufacturer are made with the use of best quality components and are available at economic prices. Functioning :The material is moved to the Hammer Mill once it is out from the second hopper. The principle involved is that materials get crushed with the impact of the swinging hammers. The material reaches out to the grinding chamber after it is fed from the top of the Hammer Mill. Rotating hammers made up of manganese come in contact with the material which is then crushed to the desired extent and then are made to pass through the perforated screen. Then the material is sent to the screw conveyer and is transported to second bucket for storage silo. Attributes : Robust construction Efficient High performance Low maintenance Used for : Grinding different types of free flowing materials

Super Hammer Mill

75,000 Per unit

Grain Hammer Mill

Get Price Quote

15 Models (Upto 200 HP) * Ideal For Precrushing & Coarse Grinding * 50 To 25,000 KgsHr.Cap. * Cool Grinding * Low Power Consumption * 3 in 1 Unit (pulverizing, Sieving & Conveying) * Available with Negative Pressure System also. * Wet milling also available. * Grinding element in different shape to application. * Bottom Discharge Also * Side Screen Opening Also * With Star Type Hammer * M.O.C. In MSSS

Maize Grinding Hammer Mill

Get Price Quote

Hammer Mill, Disintegrator Mill

Get Price Quote

The Hammer Crusher/Disintegrator is widely used in the industry of mining, building materials, chemical industry, metallurgies and fodder. The Hammer Crusher/Disintegrator can secondary and fine crush materials in middle or less than middle hardness such as barite, limestone, terrazzo, silica and stone, coal, coke, gypsum, aluminum sulfate, slag, etc. Features And Benefits Able to produce a wide range of particle sizes. work with any friable material and fiber. Ease of use. Lower initial investment. Minimal maintenance needed.

Maize Grinding Hammer Mill

350,000 Per unit

1 unit (MOQ)

Hammer Mill

Get Price Quote

Hammer Mill / Hammer Crusher / Lump Crusher;Hammer Mill works on the principle that most materials are crushed, shattered or ground upon heavy impact of hammers/beaters. The material is struck with grouped hammers which are attached to a shaft which rotates at high speed in the chamber. The material is crushed or shattered by the repeated impact of hammers, collisions with the chamber the walls of grinding chamber. Perforated heavy screens and bar grates covering the discharge opening allows the material to exit when it gets desired size, while keeping coarse particles in the chamber for further grinding.Features & Benefits Heavy Screen is attached with it so no further screening/sizing is required Available in MS, SS-304, Ss316 or combination of them material of construction. For Abrasive and Hard materials, High Manganese or any other hardened steel liners and hard faced hammers are provided for longer life of wear spares. Arrangement for easy replacement of Screen. Robust Construction & Lower Power Consumption.

Hammer Mill

Get Price Quote

Auto Suction Hammer Mills

Get Price Quote

We offer customers automatic suction hammer mill that comes in capacity ranging from 6 H.P. To 85 H.P. Available under the brand name 'Techno Wings' these automatic machines maintain due to continuity flow through automatic suction through motor. Further, the ampere of motor does not fluctuate, hence increasing the working capacity of machine. The basic principle is straight forward. A hammer mill is essentially a steel drum containing a horizontal rotating shaft or drum on which hammers / blade are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper. The material is impacted by the hammer bars / blade and is thereby shredded and expelled through screens in the drum of a selected size. Key features of auto suction hammer mill Less operating cost due to automatic feeding. The size of cyclone body tank is bigger in these hammer mills. Automatic operations less production cost Easy to work & collect ground material without air pressure, due to dust collector. Through rotary suction machine red chili, cumin, coriander, husk of ground nut, rice bran, seeds of aratictrec (batool) soya bean are automatically sucked. Due to availability of beater carbides in automatic machines, it is not necessary to change beater frequently, which also ensures that production is not effected. Separate motor for hammer mill, blower, and rotary feeder, thus ampere of motors does not fluctuate, hence increasing the working capacity of machine. Operating principle of auto suction hammer mill The materials to be ground into the crushing chamber of auto suction hammer mill from feed hopper by gravity or through an automatic rotary feeder the carbides blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverises the material. The ground materials are continuously sucked by a centrifugal blower through screens placed at the bottom periphery of the crushing chamber and conveyed through a pipe into the cyclone dust collector for bagging. Excess air filtered through an air classifier. Particle size varied using screens with different size holes. Standard accessories of auto suction hammer mill 3 numbers motor pulley. 2 number cotton balloon. Anti-vibrating foundation stand with adjustable rail for motor. A set of perforated round holes screen are supplied with the machine. Extra accessories of auto suction hammer mill Suitable totally enclosed fan cooled three phases or single phase sq. Cage motor as per is: 325 or 996. {electricity (special power can be accommodated): 220/380/415 volts, 50/60 Hz, 3 phase} Suitable miniature circuit breaker as per is: 8828 with 3 meter cable & 3 pin top as per is: 1293 for single phase electric motors. Starters, main switch, ampere meter, capacitor for single phase electric motor. Foundation bolts V belts Magnetic hopper All contacting parts stainless steel 304 / 316 van be accommodated Application of auto suction hammer mill Hammer mills are exclusively meant for the grinding of turmeric, red chili, cumin, coriander, mango powder, sugar, wheat for ladu, salt, coffee, ayurvedic / homeopathic medicines herbs, roots, leaves, bark, dry fish, cattle and poultry feeds, food colors and so on so forth at large scale basis. Construction of auto suction hammer mill Rotary feeder is supplied with gear box. Hammer mill made from heavy duty mild steel fabricated body. Grinding chamber lined with serrated wear plates, which protects the body from wear and tear. Grinding is done by a set of swinging blades or hammers on a balanced rotor. A screen classifier forms the lower half of the grinding chamber. Blower is driven on a separate shaft with the help of a 'v' belts & separate motor.

Hammer Mill

Get Price Quote

Ultra Febtech Pvt. Ltd. make a Hammer mill which is used for the materials that are grounded on the impact of the hammer. The feed is at the top and while rotating in the grinding shell; it is often allied beaten by the swing type hammers fixed to the rotor. It is crushed by frequent contact of hammers and wall. A screen is round the rotor, which prevents the bigger particles to escape from the chamber. The mill is made in SS and MS.

Hammer Mill

Get Price Quote

Copper Plated Cylinders, Ready To Engrave Cylinders

Hammer Mills

Get Price Quote

Hammer Mills, Ice Crushing Machines, Cashew Dryer, Laboratory Ball Mills

Hammer Mill

Get Price Quote

Fabricated Equipments, hammer mill parts, Horizontal Ribbon Blender

Industrial Hammer Mill

Get Price Quote

Industrial Hammer Mill, Cattle Feed Plant

Hammer Mill

Get Price Quote

Grinding Machinery, mini pulverizer, ribbon blander, Wet Grinder

Hammer Mill

Get Price Quote

Guar Gum Powder, Food Processing Machines, Ultrafine Grinder

Hammer Mill

Get Price Quote

Ultra Fine Grinder, size reduction machinery, Food Processing Machine

Hammer Mill

Get Price Quote

Grinding Machinery, Air Classifier, U Type Mixer, Air Lock Valve

Hammer Mill

Get Price Quote

mining exploration, Food Processing Machinery, hotel equipment, Wet Grinder

Hammer Mills

Get Price Quote

Hammer Mills, Ball Mills, Material Handling Equipments