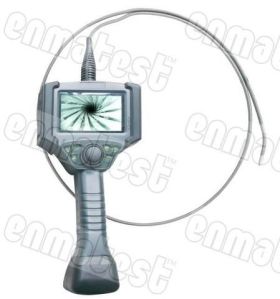

VT Series Video Borescope

285,000 Per Set

1 Set(s) (MOQ)

Illumination Type and power supply control : Illumination Type - White LED Light intensity - 65000Lux Color Temperature - 5600k Lamp life - above 10000 hours Power supply - DC12V 1A Portable battery - Li-polymer 5V 4500 mAH Image Display technical specifications : Specification of Monitor - 4.3" TFT LCD Resolution - 800 X 480 Image signal Output - CVBS Composite video Image storage and processing specifications : Video storage format - DI - 25f/s VGA - 30f/s Image storage format - JPEG Storage capacity - 8G(up to 32G) Host performance and working environment : Host control mode - Handset integrated operation System Weight - 0.95kg System Operating Tempe ration - -10o to 50o Relative humidity - 30%-80%RH

...more

Vickers Hardness Tester (VM-50 PC)

Features : Fully Computerised (PC Based) Vickers Hardness Machine. Direct and accurate measurement of Vickers Hardness number using "State of the Art" image processing technology. Wide testing range : from soft metal up to hardest. High accuracy and repeatability of measurement at all loads. Faster measurement yielding to higher productivity. Small size of indentation makes it a non destructive testing on finished components. Motorised loading and unloading cycle. Small loads allow testing of thin sheet metals. Advanced Window XP based software : Latest GUI Features : User friendly software with Windows Features. Online indentation setting and focusing on PC monitor. Advance image processing : Algorithms implemented for precise calculation of hardness numbers with various options to cover all ranges of specimen. Batch file Processing : Option for Data, storage and reports generation. Statistical Evaluation : Software forcalculating standard deviation, mean, medium, histogram etc. Wide options in calibration mode. Calibration / Verification on PC monitor makes easier to operate. Specifications : 'FIE' Computerised Hardness Tester is a simple and accurate means to produce automatically measure the diamond indentation to give Vickers hardness numbers. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard and their accurate results are widely acclaimed. These testers strictly confirm to IS 1754 - 2002. PC requirements : Intel Pentium IV 2.00 GHz or above processor is recommended. Microsoft Windows 98SE or above (Recommended XP) System Ram : 128 MB or above (Recommended 256 MB) One RS 232 (serial) port. (PC not included in standard scope of supply) Construction : The robust machine frame is designed to accommodate the high precision loading. Specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied on a diamond indentor by means of a lever and weights. After a specific lapse of a time the load is removed automatically. The image is digitized using a CCD camera fitted on the machine and is captured by PC. The diagonals of the indentation are automatically measured by PC to give the Vickers Hardness Number.

...more

Vickers Hardness Tester (VM-50)

Features : Testing range is very wide, from soft metal such as lead, upto the hardest, like hardeness steel. Same hardness number is obtained on the same specimen, regardless of the load applied. The indication is tiny and allows testing of a precision finished part. Loading and unloading cycle is motorised. Thin sheet metal is perfectly tested because the load applied is very small. Built-in projection screen to get accurate results. Specifications : 'FIE' Vickers Hardness Tester is a simple and accurate means to produce and measure the diamond indentation. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range from soft to hard and their accurate results are widely acclaimed. These testers strictly conform to IS : 1754 and ISO 6507-2. Construction : The robust machine frame is designed to accommodate the high precision loading system and an optical projection screen. Specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied on a diamond penetrator by means of a lever and weights. After a specific lapse of time, the load is removed automatically. The objective is indexed with the test piece and the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

...more

TWIN Rockwell Cum Superficial Hardness Tester

Trinocular Metallurgical Microscope

Trinocular Observation Head : Siedentopf observation head inclined at 45°. Vertical phototube for micro photography light split (80:20). Diopter adjustment ring on ocular tube (±5). Interpupillary distance from 54mm to 75mm. Objectives (Infinity Corrected) : M Long Working Distance Plan Achromatic 5X M Long Working Distance Plan Achromatic 10X M Long Working Distance Plan Achromatic 20X M Long Working Distance Plan Achromatic 50X ( S L ) Dry Mechanical Body : Co-axial focusing system with large knobs, PRE-FOCUSING LEVER & TENSION ADJUSTMENT RING. Quadruple nosepiece on ball bearing. Mechanical stage is 180mmX155mm. Moving range - 75mmX40mm. The Mechanical stage has low positioned co-axial controls on ball bearing guide ways.

Weight : 1-3kg

Power Source : Battery

Eyepieces : WF15X

Vision Angle : 5-10Degree

...more

TH-170 Digital Portable Hardness Tester

33,500 Per Set

1 Set(s) (MOQ)

YAMAYO BLISS 'TH 170' is an advanced hardness tester distinguished by its high accuracy due to Lemo connectivity, wide measuring range and simplicity of operation. It is most suitable for testing of various kind of Metals.Main Features : Highly accurate (± 4HL @ 800 HL). Integrated display of results for all common hardness scales. Large, Clear & high contrast LCD for optimum viewing in all conditions. Easy calibration & Low Power consumption. Battery - 3 * 1.5v AAA no charging required Standardization - ASTM A956; DIN 50156. With Standard Accessories : Main Display Unit TH – 170 Impact Device ‘D’ (with Impact Body ‘D’ , Cable, Support Rings) Test block with HLD value Little Support Ring Charger Cleaning brush Calibration Certificate Instruction manual Carrying case Optional Accessories : Set of Support Rings (12 Pcs.)

Accuracy : ±4HLD

Hardness Scale : HL, HRC, HRB, HV, HB, HS

...more

TH - 160 Digital Portable Hardness Tester

Developed model of TH140 On-Board memory holds 240-1000 groups of data Automatic identification Impact Device and test direction (Except G) Time and date setting, auto-clock Integral thermal printer, print all test results and histogram Li Battery, Low voltage indication and sound alarm Dataview for PC operation Software data and upper lower limits setting and sound alarm Software to connect with PC Large LCD with back-light, showing all functions and parameters Direct Display of tensile strength (U.T.S.) For all metallic materials Wide measuring range (see next page) Six Impact Device are available for special applications Standard delivery Main Unit with removable printer Impact Device Test block with HLD value Charger Cleaning brush Time certificate Instruction manual Carrying case 1111111 Optional accessories Printing paper Special Impact Device Support Rings

Hardness Scale : HL, HRC, HRB, HV, HB, HS

Accuracy : + 6HLD (760 + 30HLD) error of displayed value 6HLD (760 + 30HLD) repeatability of displayed value

Power : Rechargeable Li Battery, pile for TH160

...more

TH - 134 Digital Portable Hardness Tester

Main Unit integrated with Impact Device DL Test block with HLD value Charger Cleaning brush Carrying suitcase Time certificate Instruction manual Warranty card Carrying case Standard delivery Main Unit integrated with Impact Device DL Test block with HLD value Charger Cleaning brush Time certificate Instruction manual Carrying case 1111111 Optional accessories support Rings Printer TA220S with cable

Hardness Scale : HLDL, HB, HRC, HRB, HV, HS

Accuracy : + 12HLDL

Power : Rechargeable NiMH battery

...more

TBS Series Video Borescope

Functions and Features : Quick snap Quick video recording Quick review Av out Video/picture viewer 16 Language selected 3.9mm~10mm Lens 1m~30m Cable 640×480 Resolution Details TBS-2486 Industrial Video Borescope Approx. Rs 48,000 / Piece

...more

TBS-2486 Video Borescope

48,000 Per Piece

Functions and Features : Quick snap Quick video recording Quick review Av out Video/picture viewer 16 Language selected 3.9mm~10mm Lens 1m~30m Cable 640×480 Resolution

Power : DC 5V

...more

Surface Roughness Tester TR100

Pocket-size & economically price Large measuring range suitable for most materials Measures flat, outer cylinder and sloping surface Both Ra and Rz parameters in one instrument Features external calibration at keyboard Standard conform to ISO and DIN Rechargeable batteries, work while charging Standard delivery Main unit Protection cover for pickup Specimen Ra Charger TIME certificate Instruction manual Warranty case

...more

support rings

Material : Metal

Shape : Round, Square

Thickness : 5-10mm

Application : Industrial

Feature : Accurate Dimension, Heat Resistant

...more

Superficial Rockwell hardness tester

Model : RASN ( T ) Suitable for Rockwell & Rockwell Superficial Tests. Manually Operated. Preliminary Test Force - 29.42, 98.07N (3, 10kgf). Additional Test Force - 177.7, 264.8, 411.9, 490.3, 882.6, 1373N (12, 27, 42, 50, 90 & 140 kgf). Total Test Force - 147.1, 294.2, 441.3, 588.4, 980.7, 1471N (15, 30, 45, 60,100,150 kgf). Test Force Selection by external dialing. Auto zero setting dial gauge. 'FIE' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes. The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. Our Hardness Tester confirm to respective standard as under. IS : 5073, BS 10189-2 & ASTM E-18 for Rockwell Superficial Test. Additional Information: Item Code - RASN-T

...more

Shore Hardness Tester

Technical Specifications : Digital durometer for shore hardness testing pocket size Shore Hardness A DIN 53505, ASTM D2240, ISO 7619, JISK 7215 Hardness Result, Average Value, Max. Value Hardness Range 0 - 100 HA Measurement Deviation < 1% H Resolution 0.1 Auto switch off with RS232C interface Operating temperature 0 - 40°C Power supply 4 X 1.5V AAA (UM - 4) Battery Low Battery indicator Dimensions: 162 mm x 65 mm x 38 mm Weight 172 gm Standard Delivery : Main Display unit Test Specimen Pocket case Certificate Instruction manual Carrying case

Measurement Deviation : < 1% H

...more

Rockwell Hardness Tester

Rockwell, Rockwell Brinell Combined, Rockwell / Rockwell Superficial Combined System Hardness Testers. SAROJ Hardness Testers Model RAS, RAB,-1, RAB-250, TWIN are manually operated. All these models are suitable for testing hardness of metals and alloys of all kinds hard or soft, whether flat, round, or irregular shape. These testers are simple in design and easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for schools, laboratories, tool-rooms, inspection, heat treatment department, factories, etc. These testers strictly conform to IS : 3804 - 1988, BS : 891 parts 1 & 2, ASTM : E 18 for Rockwell test. IS : 2281 - 1983, BS : 240, ASTM : E 10 for Brinell test and IS 5073 - 1988 ASTM : E 18 for Rockwell Superficial Test. RAS : Automatic load selection with automatic zero setting dial gauge. Manual operation. RAB-1 : Automatic load selection with automatic zero setting dial gauge. Facility for Brinell tests with 187.5 kgf. load with 2.5mm Ball indentor, additional load 250 kgf. with 5mm Ball indentor for testing hardness of non-ferrous metals.

...more

Rockwell Cum Brinell Hardness Tester

RASNE Series Digital Rockwell Hardness Tester

Principal : Rockwell, Rockwell superficial & Rockwell cum Brinell tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. RASNE series machines are suitable for Rockwell, Rockwell superficial & Rockwell cum Brinell tests. These are motorized digital Hardness testers having LCD display for easy hardness measurement. The results are displayed in 0.1 Rockwell unit for more accurate measurement. Operation : Various parameters of test can be set on front panel by operation of key board and observing LCD display Viz high/low limits, dwell time, auto/manual start, printer selection, scale selection etc. All set data can be verified edited by pressing SCL key one after another. Machine operation is very simple. The normal mode is a bar followed by "SET" indication. Raise elevating screw slowly through bar indication till "SET" position which will show "PRESS START" indication. Now press "START" button. Loading/unloading cycle will be completed and hardness is shown on LCD display with High/Good/Low indication. Lower down elevating screw. Panel will show normal mode for next test. Also when required 'AUTO START' on front panel by operation of key board & observing LCD Display then raise elevating screw slowly through bar indication till "SET" position then it will starts loading/unloading cycle automatically & hardness is shown on LCD Display with High/Good/Low indication. FIE's new 'RASNE' series of Hardness Testing Machines come with much improved design & look with following major design changes. This is motorized machine having automatic loading/unloading cycle suitable for production testing. The machine body is having a taper front look and a large size read-out in the front. The machine is powder coated for better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is retained for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enables testing of small dia. Pin or ball upto 3 mm dia. These models are provided with automatic working cycle and digital LCD display with 0.1 Rockwell resolution. This insures productivity with better accuracy. IS:1586:2000 for Rockwell and superficial test. IS:2281:2005 for Brinell Hardness Test. Note : For Brinell scale - manually select (187.5 or 250 kgf) with respected ball indentor. At that time take reference of set point only. Apply the load, then measure the impression dia by Brinell microscope only. (No Brinell scale display on screen). Optional Accessories : Steel ball indentor 1/8", 1/4", 1/2". Testing Table 20mm dia. Testing Table 70mm dia. with 'V' groove for round jobs 10 to 80mm dia. Vari-rest to support add shaped jobs. Jominy test fixture for end quench test. Gooseneck Adoptor No.1. Special diamond indentor suitable for Gooseneck Adoptor No.1. Short nib diamond indentor suitable for Goodseneck Adoptor No.1. Gooseneck Adoptor No.2. Special diamond indentor suitable for Goodseneck Adoptor No.2. Gooseneck Adoptor No.3. Raised center testing table 15mm dia. Diamond Spot Anvil. Cylindron anvil for testing big jobs above 20mm dia. Eyeball anvil with 25.4mm dia. or 38mm dia. ball. Gooseneck anvil for pipes 5 to 25mm ID with 5mm step inserts. Jack rest for long and heavy jobs.

...more

RASN-T Superficial Rockwell Hardness Tester

Rockwell Cum Rockwell Superficial Hardness Tester : Model - RASN ( T ) Suitable for Rockwell & Rockwell Superficial Tests. Manually Operated. Preliminary Test Force - 29.42, 98.07N (3, 10kgf). Additional Test Force - 177.7, 264.8, 411.9, 490.3, 882.6, 1373N (12, 27, 42, 50, 90 & 140 kgf). Total Test Force - 147.1, 294.2, 441.3, 588.4, 980.7, 1471N (15, 30, 45, 60,100,150 kgf). Test Force Selection by external dialing. Auto zero setting dial gauge. 'FIE' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes : The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. Our Hardness Tester confirm to respective standard as under. IS : 5073, BS 10189-2 & ASTM E-18 for Rockwell Superficial Test.

Voltage : 220V

Power : 1-3kv

Warranty : 1year

Frequency : 50Hz

...more

RASN Series Rockwell Hardness Tester

Model : RASN Suitable for Rockwell Tests. Manually Operated. Preliminary Test Force - 98.07 N (10kgf). Additional Test Force - 490.3, 882.6, 1373N (50.90, 140 kgf). Total Test Force - 588.4, 980.7, 1471N (60, 100, 150 kgf). Test Force Selection by external dialing. Auto zero setting dial gauge. Rockwell cum Brinell Tester, Model RASN (B). Same as RASN above in additional Additional Test Force - 1471, 2354N (177.5, 240 kgf). Total Test Force - 1839, 2452N (187.5, 250 kgf). 'FIE' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes. The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. Our Hardness Tester confirm to respective standard as under. IS : 3804, BS 10109-2 & ASTM E-18 for Rockwell Test. Additional Information: Item Code - RAS-N

...more

RASN Rockwell System Hardness Tester

Rockwell System Hardness Tester : Model - RASN Suitable for Rockwell Tests. Manually Operated. Preliminary Test Force - 98.07 N (10kgf). Additional Test Force - 490.3, 882.6, 1373N (50.90, 140 kgf). Total Test Force - 588.4, 980.7, 1471N (60, 100, 150 kgf). Test Force Selection by external dialing. Auto zero setting dial gauge. Rockwell cum Brinell Tester, Model RASN (B) : Same as RASN above in additional Additional Test Force - 1471, 2354N (177.5, 240 kgf) Total Test Force - 1839, 2452N (187.5, 250 kgf) 'FIE' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes : The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. Our Hardness Tester confirm to respective standard as under. IS : 3804, BS 10109-2 & ASTM E-18 for Rockwell Test.

Voltage : 220V

Power : 1-3kv

...more

RASN-M Motorised Rockwell Hardness Tester

Principal : Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value.Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell hardness number.Operation : For Rockwell & Rockwell Superficial Test In case of 'RASN' series machines for Rockwell & Rockwell superficial tests a preliminary test force in first applied and then indicator is automatically set for zero. Quickly thereafter an additional test force is applied without removing the preliminary test force. When the penetration is stabilised, the additional test force is removed and the hardness number is shown directly on the indicator.For Brinell Test : The operation is exactly same as above. However, the diameter of impression is measured outside of machine by Brinell microscope. Brinell hardness number is found out by referring corresponding hardness tables showing hardness number against dia. of indentation for specified ball diameter and test force.'FIE' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes. : The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. Our Hardness Tester confirm to respective standard as under. IS : 2281, BS 10003-2 & ASTM E-10 for Brinell Test.

Power : 1-3kv

Frequency : 50Hz

...more

RASN-ET Series Digital Rockwell Hardness Tester

Rockwell and Digital Rockwell Hardness Tester consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. RASN-ET series machines are suitable for Rockwell and Rockwell superficial tests. These are motorized digital Hardness testers having LCD display for easy hardness measuring. The results are display in 0.1 Rockwell unit for more accurate measurement. Operation: Various parameters of test can e set on front panel by operation of key board and observing LCD display Viz high / low limits, dwell time, auto / manual start, printer selection, scale selection etc. All set data can be verified / edited by pressing SCL key one after another Machine operation is very simple. The normal mode is a bar followed by "SET" indication. Raise elevating screw slowly through bar indicator till "SET" position which will show "PRESS START" indication. Now press "START" button. Loading / unloading cycle will be completed and hardness is shown on LCD display with High/ Good / Low indication. Lower down elevating screw. Panel will show normal mode for next test Additional Information: Item Code - RASN-ET

...more

RAS Series Rockwell Hardness Tester

RAS : We are among the top most Manufacturers and suppliers of Rockwell Hardness Tester. They provide the facility of Automatic load selection with automatic zero setting dial gauges. Technical Specifications : Loads 60, 100, 150 kgf Initial Load 10kgf Max. Test Height 230mm Depth of Throat 133mm Max. depth of elevating screw below base 240mm Size of base 170 x 430mm Machine Height 655mm Net Weight 65kg Standard Accessories : Testing table 50mm dia 1 pc. Testing Table 38mm dia with 'V' groove for round jobs 6 to 45mm dia. 1 pc. Diamond Indenter 1 pc. Stell ball indenter 1/16" 1 pc. Test Block Rockwell 'C' 1 pc. Test Block Rockwell 'B' 1 pc. Test Block Rockwell Superficial 'N' NIL Allen Spanners 5 pcs Clamping Device 1 pc. Dash Pot Oil 1 Book Rubber bellow for elevating screw protection 1 pc. Instruction Manual 1 Book

...more

Portable surface roughness tester

All Functions for convenient Operations : Complies with major International standards such as ISO, DIN, CNOMO, JIS, ASME Data Memory/Battery Operation: Ten complete Data records can be stored.Rechargeable battery operation provides versatile usof the line independent of the line supply. Measuring in different positions: The small and light handysurf measures not only flat,horizontal,but also vertical and overhead surfaces. Direct data Transfer to the PC- The RS 232 serial interface is used to transfer measured data,parameters and profile curves directly to the PC.

Power Source : Electric

Warranty : 1year

...moreOpening Hours