Burnout Furnace with Programmable Timer

Get Price Quote

1 Piece (MOQ)

Heat Treatment Furnaces

Get Price Quote

1 Piece (MOQ)

Best Deals from Heating Furnace

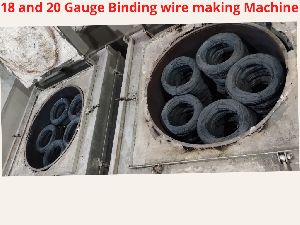

wire annealing furnaces

Get Price Quote

We are profound wire annealing furnace manufacturers and suppliers in India. These furnaces are suitable for annealing of ferrous and non-ferrous materials. Shivang Furnace is the premium manufacturer and supplier of heat treatment solutions. It is leading the market of steel wire annealing furnaces suppliers. Engineers of the company specialize in manufacturing kilns and furnaces for industrial customers across the globe. Leading wire annealing furnace exporters in India, Shivang Furnace is a reputed name in the market.

Tempering Furnace

Get Price Quote

We have reliable, legal, and secure payment procedures through which clients can make purchases. We maintain a high level of transparency and ensure to maintain proper documentation. Our products are tested on various parameters during the production process to ensure their adherence to the industrial quality standards.

galvanizing furnace

Get Price Quote

In the hot dip galvanizing process, the zinc is molten at the 450 °C or above temperature prior to immersing of the respective article and to achieve such a high temperature hot dip galvanizing furnace is essential, a furnace that is highly efficient, reliable and capable to heat the zinc kettle surface evenly. By owing the requirement of the highly efficient hot dip galvanizing furnace, Corrotech comes out with the hot dip galvanizing furnace made by leveraging our overlong experience in the allied industry along with the deep know how associated with galvanizing. This offered hot dip galvanizing furnace is fabricated using utmost quality mild steel that has a capability to withstand the high temperature changes, whereas casing of this hot dip galvanizing furnace is thickly insulated by exploiting supreme quality ceramic fibers and modules. The exclusive features that make our Hot Dip Galvanizing Furnace exclusive are: Low Fuel Consumption High Recirculation of Furnace Gases Uniform Temperature Distribution Optimum Heat Transfer Low Ash Formation Low Dross Formation Less Maintenance Cost

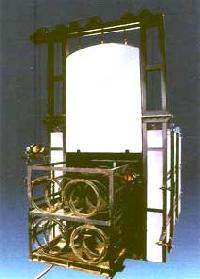

Bright Annealing Furnace

Get Price Quote

Bright Annealing Furnace vendor has about 30 years of innovative experience and can design and Produce for wide range of SS stainless product. It’s performance in term of output and product quality has given Satisfaction to customer.

heat treatment furnace

325,000 Per Piece

1 Piece (MOQ)

Wire Annealing Furnace

350,000 - 700,000 Per Piece

1 Piece (MOQ)

Loading Capacity : 2 M.T To 5 M.T Max Temp. : 900 Degree. Heating Time period : 8 to 10 Hours

smelting furnaces

5,000 - 9,000 Per Piece

Pit Type Gas Carburizing Furnace

Get Price Quote

GAS CARBURIZING FURNACE We Provide A Large An Blissful Range Of Quality Pit Type Gas Carburizing Furnace with Long Lasting Feature And Better Conduction Properties Manufactured With Extreme High Quality Products By Our Team Of Skilled And Unskilled Workers Under The Guidance Of Our Reliable Engineers. We Provide Customization Of Products As Per Customer Satisfaction With On Time Deliveries And Affordable Price. Pit Type Gas Carburizing Furnace Specifications: High Reliability Smooth Working Rigid And Super Conducting Pit Type Gas Carburizing Furnace Features: Regulates Smooth Working Maintains Pressure Maintains Smooth Flow Overwhelms Friction Compact Design

electric annealing furnace

350,000 - 450,000 Per Pieces

1 Piece(s) (MOQ)

Electric Annealing furnace used for making the Ms wire to soft, by using heating upto 850 degrees with capacity of 3 ton

Continuous Casting Furnace

Get Price Quote

Hot Dip Galvanizing Furnace

Get Price Quote

Ferrotherm designs hot dip galvanizing furnaces with high velocity burners that have long lasting proven performance on delivering high production volumes, low fuel & zinc consumption, high kettle life and requiring less maintenance. The furnace could be designed as dual fuel, oil only or for gas only as fuel. The furnace uses pulse fired high velocity burners that fire high-off or high-low to control temperature input. Burners are at or near their maximum firing rates when on. Therefore, they yield the highest possible convective heat transfer, which continuously moves the products of combustion through the entire furnace resulting in excellent temperature uniformity.

Normalizing Furnaces

7,000,000 Per Piece

galvanizing furnace

Get Price Quote

These furnaces are offered with combustion systems suitable for heavy oil, light oil, rich or lean gas or dual fuel (oil & gas). For special application electrically heated galvanizing furnaces are also offered.

brazing furnaces

Get Price Quote

Vacuum heat treatment is a well established practice in the aerospace (OEM and repair), land based turbines, automotive and tool industries. Controlled thermal processing of components is carried out in a vacuum environment to eliminate the deleterious effects of the charge reacting with the gases present in air. The main advantages of this process are bright oxide-free finishes with no carburisation or decarburisation, controlled heating and repeatability without hazardous fumes or toxic waste.

heat treatment furnace

Get Price Quote

Stress Relieving Solutionising Aging All tempers can be provided in-house.

Preheating Furnace

100,000 Per Piece

Aluminum Annealing Furnace

Get Price Quote

Aluminum Heat Treatment Furnace is used for Annealing, Normalizing, Hardening, Stress Relieving, Solution Annealing, Tempering, etc. of various grades of Aluminum in the form of forgings, castings, fabricated components etc. Inherent features of this product are : Robust MS shell to withstand continuous operation. Sturdy bogie design to take care of the charge weight Furnace can be offered with single bogie or double bogie, Heating elements operating on low surface load for longer elements life and continuous trouble free furnace operation. Refractory and insulation of high quality bricks / ceramic fiber for energy conservation. Heat loss prevention by Ceramic Fiber rope for door. Perfect temperature uniformity in the furnace useful space. Automatic temperature control by PID Temperature Controller. Electrical switch gear items of reputed make, along with controller housed in aesthetic control panel. Safety interlocks and protection devices for safe furnace operation. Areas of application : For Heat Treatment process of Aluminum like, Annealing Tempering Nitriding Aging Quenching Hardening Chamber Sizes : Custom built to suit customer’s specific requirements. Temperature Ranges : Up to 650°C Heating Medium : Electrical Control Panel Thyristor Based Power Control Panel. Temperature Based Power Control Panel.

Hardening Annealing Furnace

Get Price Quote

We offer Hardening Annealing Furnace.

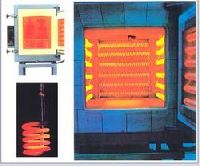

Heating Furnace

Get Price Quote

Unique and Indigenously developed IGBT based design for exceptional per formance and adaptability for severest foundry environment. Revolutionary Self-Tuning Peak Power Tracking Circuit giving 10-20 % Higher production for the same load Demand and Lesser Power consumption.Admirable and Str ingent Quality standards.

Furnace Oil Heating Pumping Filtering (HPF) Unit

Get Price Quote

» COMBUSTION TECHNOLOGY is an art, please consult us for your specific combustion needs. General Information: » Oil Preparation - A vital phenomena for the efficient operation of low air pressure and pressure jet oil burner is available as a factory finished units in duplex - semiduplex and simplex versions. They are comprising of oil heater fitted with renuable cantrege type heating element, gear oil pump with motor, oil filters, bail valves, pressure regulating valves and instrumentation. Range Capacity: » 1 KW to 200 KW Oil Pressure: » 1 Kg/cm2 for LAP Burner » 15 Kg/cm2 for Pressure Jet Burner Details required for Quotation: » Application » Type of Fuel » Working Temperature (°F Or °C) » Ambient Temperature (°F Or °C) » Working Pressure

crucible furnaces

Get Price Quote

heat treatment furnace

325,000 Per Units

1 Units (MOQ)

Spring Tempering Furnace

Get Price Quote

We offer highly efficient Spring Tempering Furnace that is widely used in textile industries. The Spring Tempering Furnace we bring forth is manufactured using high quality materials and we use High carbon A spring steel Wire for cans spring. These Spring Tempering Furnaces are extremely easy to use and maintain. Our Spring Tempering Furnace has a superior design and advanced features. We offer our clients our Spring Tempering Furnace at industry leading prices. AttributesMade with high quality materialsConforms to Industry StandardsReasonable pricesUsed extensively in the Textile Industry AdvantagesAll processes are automaticEasy to maintainHigh efficiencySuperior design

Cupola Blast Furnace

150,000 - 300,000 Per Kilogram

Electric Induction Heating Furnace

100,000 - 1,000,000 Per Piece

1 Piece (MOQ)

induction holding furnace

Get Price Quote

induction holding furnace, Distribution Transformers, ladle refining furnaces

Heat Treatment Furnaces

Get Price Quote

We offer heat treatment furnaces. Viki refractory works manufactured heat treatment furnace and supplies all type furnace . Viki refractory works offers a range of the highest quality industrial heat treatment furnaces with the following features.

Heating Furnace

Get Price Quote

Heating Furnace, TMT Steel Bars, steel plants, tmt reinforcement bar