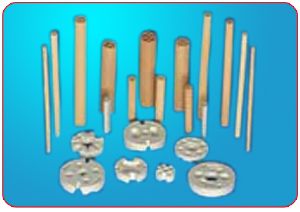

thermal insulator

steatite ceramic

Steatite is mainly used to manufacture Electrical Insulators Steatite is magnesium silicate Steatite has good Mechanical Strength High volume resistively up to 1000 degree C Good dielectric strength Low dissipation factor Impervious material structure Steatite is commonly used in appliance thermostats where a high temperature electrical insulator is needed that will hold its shape and size and will not wear out during the life of the device. Steatite works very well in cold switching applications. Steatite is used to support heating elements in electric heaters, toasters, and ovens. Steatite is a good high voltage insulator. It holds up under thousands of volts without breaking down. Steatite ceramic parts are usually small and are formed from dry powder in a compaction press. The parts are then fired in the kiln. Diamond abrasives are used to grind parts to size for high tolerance applications.

...more

Special Ceramic

porcelain

Porcelain is more readily formed into larger shapes Porcelain is very easy to glaze and is used extensively as insulators for overhead power transmission lines Porcelain is easily formed by Wet Pressing, where as Steatite is not

...more

Ind Ceramic

We are offering Ind Ceramic

Cordierite Ceramic

Cordierite is a ceramic used in heat shock applications that would crack and shatter most other ceramic materials.Kiln furniture is made of cordierite because it will survive thousands of heating and cooling cycles.At Paratech all of our production is placed in cordierite trays known as saggers to be used in the kiln during the firing cycle. Cordierites have excellent resistance to heat shock, due to their low coefficients of thermal expansion. Cordierites come in a range of thermal expansions, mechanical strengths and porosity's Cordierite ceramics make cost-effective insulators wether dry-pressed or extruded At K.C. Industries we make both a Dense Cordierite and a Cordierite with high porosity Cordierite that we call, Cordierite Refractory Small cordierite parts can be dry powder pressed. Large cordierite pieces are formed by slip casting.Slip casting is a process where the ceramic material is mixed with water and poured into a plaster mold. After a few hours the plaster draws off the water from the mix and the sagger or other shape can be released from the mold. Parts are then dried and fired.

...more

Cordierit Refractory

Cordierite Refractory or open porosity Cordierite has a low coefficients of thermal expansion and therefore performs better in thermal shock applications The open porosity however makes this body highly unsuitable for electrical insulation purposes, especially in humid conditions Technical ceramics engineering technology is helping to solve more and more mechanical, electrical, and electronic engineering problems, with applications in diverse fields such as automotive, power, manufacturing, consumer and telecom industries.

...more

Special Ceramic & L.T.Insulator

Be first to Rate

Rate ThisOpening Hours