vertical surface grinder

Ideally suited for heavy stock removal with high degree of accuracy combined with economic method of grinding for engine block, cylinder head, refractory bricks and many other rgeneral engineering components.

...more

Vertical Machining Center VMC 800M

Bed type machine configuration Preloaded linear recirculating guideway system AC Spindle motor ACervomotors for feed drive of all axes. Automatic cyclic lubrication system for ballscrews and guideway system. Chip collection arrangement with chip conveyor. Guideway protection through telescopic coversbellow covers. Machine work lighting. Cam driven high speed armless auto tool changer. External coolant Head counter balance

...more

Vertical Machining Center VMC 500M

Fixed column type machining center. All axes with LM guideways High power for large metal removal rate, power adequate for extensive milling with latest carbide cutters. Absolute encoders for all axes. Encoder for faster spindle orientation.Spindle supported on a set of four high precision preloaded angular contact ball bearings and is dynamically balanced. Immediate spindle start-up eliminate4s lost machining time. All axes drive by maintenance-free AC servomotors with excellent response characteristics for accurate contouring. 12-Tool magazine. Designed for high accuracies.

...more

Vertical Machining Center VMC 400M

Machine structure designed for optimum performance from static, dynamic and thermal aspects. 12-Tools armless tool changer Z-Axis on the spindle and X, Y axes on the table Dynamically balanced cartridge type spindle unit. Direct coupled ballscrews with feed motors Absolute encoders for all axes Space saving and single lift type design. Rigid tapping High pressure coolant system TPM Friendly machine TPM Friendly machine Head counter balance

...more

Vertical Machining Center VMC 1000M / 1200M

Bed type machine configuration. Preloaded linear recirculation guideway system. AC Spindle motor AC Servomotors for feed drive of all axes Automatic cyclic lubrication system for ballscrews and guideway system Chip collection arrangement with chip conveyor Guideway protection through telescopic coverbellow covers Machine guarding External coolant Machine work lighting Head counter balance Absolute encoder for all axes.

...more

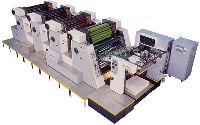

Two Colour Sheetfed Offset Printing Machine

Circumferential and lateral plate register control while the machine is in operation ,Centralised automatic lubrication with cyclic timer ,Anti-marking sheets on transfer cylinders and transfer drums ,Photo cells for detection of ‘no sheet’, ‘cross sheet’ and ‘overshoot’ of paper stock,Force cooled electrical cabinet to prevent abnormal fluctuation due to external temperature increase,Air cushions and pneumatic drums for sheet slow down at delivery to ensure smear-free perfect delivery piling

...more

Two Colour Sheetfed Offset Printing Machine

PLC based Photocell for 'no sheet','cross sheet' and 'overshoot' detection,Centralised automatic lubrication pump with timer and lubrication reminder alarm,Lateral and circumferential register adjustments for plate cylinders while the press is running,Highly reliable pressure vacuum pump,Motorised feeder pile hoist with pre-piling facility

...more

Single Colour Sheetfed Offset Printing Machine

Double roller type side pull lays with micrometric adjustment during running to ensure perfect registration HMT feeder system with superior sheet pick-up unit for reliability, ease of maintenance and efficiency to feed wide range of paper stock,Photocells for detection of 'no sheet','cross sheet' and 'over shoot' of paper stock,Double blanket system for excellent dot reproduction

...more

Radial Drilling Machine

Massive and rigid construction. Ergonomically grouped controls for operating convenience. Light centering of spindle. Precise depth release.Electrohydraulic clamping provided for drill head, arm & sleeve.Shock-free engagement of taps through clutch and spindle reverse for withdrawals.Machine with drilling capacity 80 mm 100 mm also available.

...more

Programmable Guillotines

One of the fastest Guillotines in the world with a mechanical cutting speed of 47 cuts per minute,The only Guillotine to use a pendulum action on the knife carriage bar which guarantees minimal absorption of energy by working parts resulting in reduced wear and easy accessibility for maintenance of the knife carriage and related functions,The hydraulic unit is dedicated to maintaining clamp height eliminating the need for counteracting springs,CNC controlled closed loop mechanism for accurate positioning of back-gauge eliminating the need of the electromagnetic brake mounted on the ball screw axis

...more

Precision Cylindrical Grinder

Single piece robust construction with long guided sleeve for better rigidity of tailstock. Bed made of high tensile strength cast iron, heavily ribbed for better vibration damping and shock absorption. Precision, widely placed V & flat guideways with turcite for table and infeed slide. Turcite lined table guideways for APURVA 175. Grinding wheel head spindle runs in a high precision hydrodynamic bearing. Higher powered wheel head for production model for high rate of stock removal. Spindle is nitrided and super finished for reliability and life. Automatic infeed at table reversal for traverse grinding operation. Auto plunge grinding cycle consisting of rapid approach, coarse feed, fine feed, spark out and rapid retraction. Independent drive for internal grinding attachment. PLC control for higher reliability.

...more

precision centerless grinding machine

Bed made of high tensile strength cast iron, heavily ribbed for better vibration damping and shock absorption.,Grinding wheel spindle mounted on special tilting pad type hydrodynamic bearings. Regulating wheel spindle mounted on super precision antifriction bearings for higher rigidity.Faster & easy wheel change due to cantilever design spindle. Automatic separate lubrication system for grinding wheel head spindle.

...more

precision ball screws

HMT , a pioneer in the field of machine tools with more than 50 years of expertise, also manufactures High Precision Recirculating Ball Screws of various sizes to meet Customers requirements. Recirculating ball screws have to be converted into rotary motions or vice versa. Ball screws have a high mechanical efficiency, superior positioning accuracy coupled with low wear and long life, and are widely used in various industrial machines & equipments, especially in numerical controlled machines as mechanical feed elements.

Feature : Higher Efficiency: Lesser Heat Generation: No Stick-slip: Higher Service Life:

...more

Multispindle Automat AS/ASH

Compact, low vibration portal frame construction with top mounting cam shaft, resulting in wide open tooling area, easy access to tooling and control cams, unrestricted swarf disposal. Bar automats AS series are with bar feeding and clamping feature. Chuck automats ASH series are with manual loading and unloading feature. Magazine attachment can be fitted to these machines.

...more

Medium Duty CNC Lathe B32 CNC

Designed to provide flexible, accurate, and cost effective machining (such as chucking jobs, shaft turning, ODID, profile turning and thread cutting). Infinitely variable spindle speeds, selectable in two automatic ranges. Optional 12-station tool turret in lieu of standard 8-station. Rigid tailstock with hardened and ground guideways. High precision antifriction bearings for the hardened and ground main spindle. Hardened and ground bed guideway. Both longitudinal and transverse axis (Z & X) are by ballscrews and AC servomotors with encoder feed back.

...more

Hydraulic Press Brakes

Capacities from 200 T to 1000 T. Conventional CNC controls can be offered. Fabricated steel structure fully stress relieved.Hydraulic elements of reputed make.

...more

Hydraulic Cylindrical Grinder

Designed for high rates of stock removal for batch production requiring fine tolerance limits with finest surface finish. Available in universal and production models, having infinitely variable table traverse, with a dwell and automatic infeed at table reversals. The universal models are equipped with swivelling wheel head and built-in provision for internal grinding. A single lever controls table traverse, work rotation, coolant flow and rapid approach of wheel head during production runs.

...more

Horizontal Spindle Surface Grinding Machine PSG 200

Bed made of high tensile strength cast iron, heavily ribbed for better vibration damping and shock absorption.,Precision hardened and ground antifriction roller guideways for saddle, table and vertical column.,Ideal for components requiring an extremely accurate and highly finished flat surfaces, tool room applications. High rates of output can be obtained especially in those cases where the components can be loadedclamped in batches on the table or on a magnetic chuck.

...more

High Speed Precision Lathe

Built with power, precision and versatility for achieving unmatched capabilities in precision turning. Rigid rectangular section wide bed. Short spindle and shafts for maximum drive rigidity. Straight bed and gap version with removable bridge piece. All drive gears in headstock are case hardened and ground. thermal deformatio

...more

Heavy Duty Lathe

500,000 - 1,150,000 Per piece

Heavy-duty headstock with main spindle bore of 150 mm and 1000 mm bed width to ensure increased load carrying capacity. Widely spaced carriage is provided with rapid traverse arrangement for saddle, cross slide and top slide. Dia. 1500 mm faceplate to facilitate facing operation on large components. AC Induction motor for spindle drive. Twenty-one spindle speeds, selected by lever. High precision antifriction bearings for the hardened and ground main spindle. Hardened and ground bed guideways. Carriage guideways are fixed with antifriction turcite liners for stick-slip-free movement. 4-Station manually indexable tool post. Rigid tailstock with hardened and ground sleeve with built-in rotating center. Chucks, special accessories and work holding devices in accordance with customer requirements. Can be offered with up to 5000 mm centre distance with unsupported job weight carrying capacity of 8000 kg.

...more

Heavy Duty CNC Lathe

Modern high performance heavy duty turning machine with state-of-the-art technology. Salient Features : Designed to provide flexible, accurate, high performance and cost effective machining such as ODID turning, profile turning, facing, and thread cutting. Machine can also be offered with a gap piece to accommodate large dia. components Infinitely variable spindle speed in four ranges - automatic selection.

...more

Four Colour Sheetfed Offset Printing Machine

Precision ground hard chrome plated cylinder,18 Roller inking system with 3 forme rollers ,Double Blankets for excellent dot reproduction ,Eccentric Swing Gripper for smooth sheet in feed,Programmable logic control for high reliability of the electronic controls,Motorised dampening fountain roller with stepless speed control and provision for surge control,Lateral & circumferential register adjustment for the plate cylinder while the machine is running

...more

Four Colour Sheedfed Offset Printing Machine

High grade cast iron side frames with vibration damping properties, stress relieved and precision machined ,Quick plate clamp for fast installation & removal of printing plate ,Superior sheet pick up unit to handle all types of paper from 0.05 to 0.7 mm ,Perfect ink grinding and distribution through 21 roller train with 4 reciprocating and 4 forme rollers ,Precision ground cylinders on wide journals for high print quality

...more

Five Colour Sheetfed Offset Printing Machine

Prints 1 + 4 colours retroverso ,Ergonomically designed for ease of operation,Diagnostic fault display at feeder,Reliable suction head handles effectively a wide variety of paper stocks from 0.05mm to board of 0.7mm thickness,Good blending of ink and optimum transfer to the plate for high quality results.Quick inkwater balance and thin film dampening results in good print quality

...moreBe first to Rate

Rate This