Paper Turbine Air Filter

1,000 Per Piece

1 Piece (MOQ)

Automatic Linear Type Bottle Washing Machine

850,000 - 2,250,000 Per Piece

1 Piece (MOQ)

Best Deals from Home Appliances

Static Eliminator

Get Price Quote

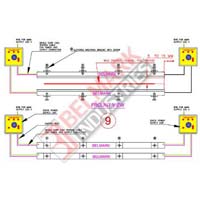

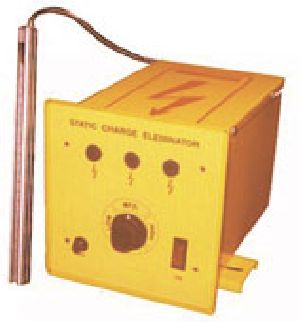

Belmark Industries is a renowned name in the market. Most of the companies trust us for the supreme quality Static Eliminator. We have grown big as Manufacturers, Exporters & Suppliers of Static Eliminator in the past few years. We owe our popularity to our dedicated staff that strives to develop and manufacture precision engineered Static Eliminator at low cost. Our Static Eliminators are highly durable, offer low cost performance and has longer life. Moreover, it is made available with easy delivery system. Details : Static electricity is a problem faced all over the world. It can affect most industries which handle non-conductive materials such as plastics, paper, board, laminates and textiles. Electrostatic attraction or repulsion causes materials to stick to machinery, or to each other, causing jams, slow machine speeds and reduced quality and productivity. Friction, pressure and separation are the major causes of static electricity. When humidity is low, higher static charges are generated .Static becomes more noticeable during winter season, when the air normally dry. Problems caused by static electricity are : Static causes Dust attraction Hazardous sparks or shocks to person Product sticking to itself, rollers or machine parts Materials tearing, jamming or curling Sheet feeding problems Static cling causes handling problem Static problems in coating, slitting & laminating Static cause problem in printing Improper stacking. Remedy to the above Problems To prevent the above one has to either neutralize the static charge or it should be conducted away to the ground. How Static Charge Eliminator Works Eliminator bars which are fixed as near as possible to the material process, on getting supply from the control unit, ionize the surrounding air and because of this, static electric charge is conducted away to the ground. Applications Extruded Tube Film Plant Tape Plant Cutting & Sealing Machine Bag Making-Printing Machine Textile Processing Machine Coating Machine Photographic Film Processing Offset Printing Machine and any other Web converting machine Power Unit Power Control Unit - Can connect upto 3 Nos. Static bars of upto 120 inches working width in the following way:- Top of Film and bottom of film in parallel (Top and bottom side of film) for entry level and one No. bar for end side is necessary. One Control Power unit have provision for connecting three static bar connections. One No. extra spare card is provided inside, so that any one of the connection fails during simultaneous use of all the three, the spare card can be used. After disconnecting the power unit, manually change the static cord from the failed card connection to the spare card connection. To do this, simply open the top cover of the Control Power Unit and change the static cord connection from failed card to the spare card. The power unit comes with one meter length 3 core power cord and static bars comes with two meter single core high power meters special cables as standard length.

Steam Press

Get Price Quote

Our Steam Press is featured with thin soleplate for better heating and provides steam of 15 gram/ minute. We are capable of meeting bulk or urgent requirements effortlessly due to our latest inventory management system and automated management. By this, the stocks are piled up safely to ensure delivery without loss. Only high quality raw materials have been used for the production of our entire range. We check the raw materials against varied quality parameters before procurement.

Cast Iron Filter Press

48,000 Per Piece

1 Piece(s) (MOQ)

Automatic Linear Vial Washing Machine

Get Price Quote

The Automatic Linear Vial Washing Machine is excellent for washing injectable glass vials of all varieties. This machine has been integrated with seven washing stations to speed up the regular process of washing with the best approach. This aspect of the machine can be customized based on the requirements of the customer. This Tunnel Type Vial Washing Machine offers four water washes and three air washes. It also offers the most positive and regulated pressurizing washes for vials. All the contact and noncontact parts are made of high quality stainless steel. The details of the variety of the material can be taken from the features that have been enlisted in the following few points. In accordance with the GMP requirements, vials are inverted into a neck down position and the nozzles are entered into vial during the completion of the washing cycles. For sterile vial filling lines, this Vial Washing Machine has proven to be the best solution till now.

Air Purifier

Get Price Quote

Keep air pollutants at bay with our next-generation air purifiers that work silently and ensure that you and your loved get the freshest and healthiest air possible. Daikin air purifiers come with state-of-the-art features such as streamer discharge technology, dust and odour sensor lamps, plasma dust collection, power-saving inverter, turbo mode and lot more. Its 6-stage filtration process guarantees enhance air cleaning all the time.

commercial washing machine

100,000 Per Piece

1 Piece(s) (MOQ)

Harmonic Filter Reactor

Get Price Quote

Vishay ESTA KEY BENEFITS Avoidance of Resonance conditions. Tuned & Detuned Harmonic filters. Reduction of Harmonic Distortion (Network clearing)

static charge eliminator

8,000 Per Piece 1

Textile industries plastic industries

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

1 Piece(s) (MOQ)

Salient Features : Geneva mechanism. Four inner, one outer and one air wash. Sequence of washes of washes to customer’s choice. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading with two rows.

automatic vial washing machine

Get Price Quote

Steam Air Vaporizer

90 Per unit

Air Purifier

5,500 Per Piece

Automatic External Vial Washing Machine

Get Price Quote

We are the main supplier of this product.

Automatic External Ampoule Washing machine

Get Price Quote

AUTOMATIC EXTERNAL/OUTER AMPOULES-VIALS WASHING MACHINES MODEL :AHEW 200 OPERATION: The Automatic External Vial Washing Machine is suitable for Round Ampoules/Vials sizes of appx. 1ml to 20 ml size with maximum speed of 200 Ampoules Vials per minute Entire Machine construction is in Stainless Steel finish including ss frame body. All parts coming in contact with water are made from SS-316 L Materials. Continues travelling of Vials on rotary station ensure the washing of each Ampoules vials from top as well as side. We offer Machine with customised options of end user for washing sequence as per customers requirements. SALIENT FEATURES : • 6 Jets for 2 washing zones • All contact parts made of SS-316 material • Machine construction in SS-304 material • Suitable for 2 ml to 3oml Vial Size with help of change parts • Washing sequence can be made as per customers requirements. • Built-in 2 ss 316 water Pumps, 1hp blower and 1 ss 316 materials Tanks • Direct In-feed of Ampoules vials from hopper/Turn Table and Exit of Ampoules Vials to connect with Ampoules or vials sticker labelling machine

Automatic Bike Washing Machine

Get Price Quote

We provide high quality Automatic Bike Washing Machine which has precise and flawless make. With our fast and modern transit facilities, safe and timely deliveries of consignments are guaranteed. We are a leading name, instrumental in offering wide assortment of Automatic Bike Washing Machine.

cast iron lamp post

5,000 Per unit

Cast Iron lamp pole.

Automatic Linear Bottle Washing Machine

Get Price Quote

CPLBW Automatic Linear Bottle Washing Machine is used for washing of bottles. Bottles will be pushed from in feed tray and then move on wire woven conveyor belt, which align the Bottle in correct position, to enter in to the carrier pocket with help of oscillating guide rails. Oscillating arm deliver the Bottle inside pocket in mouth down position over spraying nozzles. Multi jet sprayers fixed at the top cause the total external and internal surface to be washed. To avoid any possible cross contamination between two different waters. Each washing station is provided with an independent circuit. Carrier pocket is moving with indexing motion. When the baskets have completed their motion the needles are lifted. They penetrate the bottle, spraying jets of water or compressed air then return down. The baskets movement then advances by one station. Each station of bottle passes through the washing cycles selected. The duly washed bottle then delivered to the out feed tray with neck opening upward and then automatically re ordered to a drying or packing line with back pressure. Special Pocket system ensures easy and trouble free washing of bottles from outer and inner side. Indexing motion makes easier for Multi jet Nozzles / syringes to move inside bottle, when it is in stationery motion. Washing cycles can be adjusted as per customer requirement. User friendly machine, even semi skilled operator can operate the machine very easily. Low RPM but High out put. Imported pumps are provided in the machine, which gives a good pressure to wash bottles properly. Imported Gear Motor for Main drive and conveyor. A.C. Frequency drive for Main drive and conveyor. Pumps with tank (60 liters each) 3 nos. In feed conveyor belt system.

static charge eliminator

Get Price Quote

Leading Manufacturer of Static Charge Eliminator such as High Voltage Static Charge Eliminator and Handheld Static Charge Eliminator from Ahmedabad. Riding on unfathomable volumes of industrial expertise, we are engaged in manufacturing a broad assortment of Handheld Static Charge Eliminator. Features: * Negligible maintenance* Compact design* Corrosion resistance

Static Eliminator

Get Price Quote

Because of the static electric charges depending up on their intensity and surrounding atmosphere, one may see sparking or operator/ worker in surrounding area may get shock. Wherever the material is in the form of film or sheet, it may wrap around the guide rollers causing the breakdown. In printing machine & coating, laminating machine the static may result in fire on solvent based ink which can cause burning of machineries and even loss of human life. In winding process, instead of getting clean winding, one may get crease in winding. Static electric charge also attracts dust particle which gives shabby appearance to the product. Higher the speed of the machine more is the generation of static electric charge resulting into intense problem and if it is not eliminated speed of the machine is to be reduced resulting into production loss. APPLICATIONS Film Plant Extruded Tubing Plant Tape Plant Cutting & Sealing Machine Bag Making-Printing Machine Textile Processing Machine Coating Machine Photographic Film Processing Offset Printing Machine And any other Web converting machine. Laminating Printing and other converting machines

Automatic Linear Vial Washing Machine

Get Price Quote

Shree Bhagwati very critically reviewed vial washing operations in the parenteral section and found methods either very primitive or concepts with probabilities or too perfect and highly expensive. Considering above facts, a very imaginative vial washing machine Model SBVW-150 is devised to ensure simple & modular operation, where each individual vial is positively washed with maximum of seven washes. Operation: The Vial trays are directly un-loaded to the vial tray from which it is pushed on to the turn-table. The turn-table slowly and steadily feed vials to the two tracks feed worm, where vials are automatically inverted. The synchronized star-wheel places two vials, one by one to the two tracks indexing chain. The indexing chain positively carries inverted pair of vials through seven sequential washes. At the end of washing operations vials are reinvented back into original position and collected in the tray. Salient Features Very compact, rigid, & modular construction. All contact parts with D.M. water and distilled water of S.S. 316 construction and argon arc welded. The unit built on S.S. square pipe frame and totally encompassed with S.S. coverings in pleasing matte finish to avoid corrosion and ease of cleaning even from inside. The washing section is totally covered with acrylic cabinet and collecting trays ensure total removal of water in the drain or recirculation tank Absolutely simple machine, with only six change parts, which can be changed within few minutes. All exposed parts are of S.S. 304 or hard chrome plated brass for corrosion free long life. The seven sets of nozzle enter into the vials mouth during the washing operation ensuring penetration of washing medias to the core A perfect washing principle. Fixed top nozzles at each washing station ensures external washing of vials at the same time of internal washing. The flow of washing medias stop during the indexing of chain, saving straight 25% on utilities. The system of solenoid valves and optional tanks, pumps and filters is engineered for long trouble free life & fool proof operation. The machine construction allows delivery of vials into a separate room or attach directly with tunnel.

Industrial Static Eliminator

Get Price Quote

Belmark Industries is the name that you can trust upon for all your needs regarding Industrial Static Eliminator. We are counted amongst the most reputed Manufacturers, Exporters & Suppliers of Industrial Static Eliminator. We are offering precision engineered Industrial Static Eliminator that is manufactured as per international standards. We provide market with Industrial Static Eliminator at economical prices with customizable packaging options. More about Industrial Static Eliminator : Our appointed team of experienced engineers exclusively design and develop a qualitative gamut of Industrial Static Eliminator which plays a key role in destroying the static charges which are caused or produced during the operation of a high-speed machine. The eliminators are well fitted with a high voltage generator which has the electric range of approx. 220V 50 Hz AC whereas the output can range from 6 to 7.5 KV with the current flow of 20-25 MA. The Static Eliminator even sucks the dust particle which changes the look of the product. Product Features : Large effect area No maintenance Ready to install Packed in hardboard cartons

Electric Steam Iron

Get Price Quote

We are an acclaimed entity, engaged in offering a wide range of Electric Steam Iron. Being a quality-oriented organization, we assure our clients that this product is the best in quality. Our skilled professionals only utilize fine quality raw materials, while manufacturing this steam iron. Moreover, our offered product can be availed in a wide range of sizes and shapes, as per the requirements of our esteemed clients. Features: Rust proof Compact design Optimum quality

static electricity eliminator

12,500 Per Piece

air vacuum cleaner filter

Get Price Quote

air vacuum cleaner filter, air cleaner filter, air damper, Centrifugal Fan

automatic bottle washing machine

Get Price Quote

Household Appliances

Get Price Quote

Household Appliances

stainless steel home appliances

Get Price Quote

stainless steel home appliances, frypan, casrole, Sauce Pan

Charcoal Iron

Get Price Quote

Charcoal Iron, Steel Sheet, Iron chips, Iron Strip, iron powder core