Static Eliminator

Get Price Quote

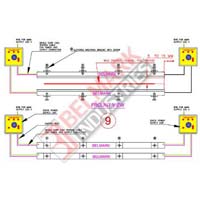

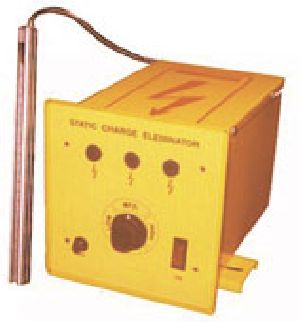

Belmark Industries is a renowned name in the market. Most of the companies trust us for the supreme quality Static Eliminator. We have grown big as Manufacturers, Exporters & Suppliers of Static Eliminator in the past few years. We owe our popularity to our dedicated staff that strives to develop and manufacture precision engineered Static Eliminator at low cost. Our Static Eliminators are highly durable, offer low cost performance and has longer life. Moreover, it is made available with easy delivery system. Details : Static electricity is a problem faced all over the world. It can affect most industries which handle non-conductive materials such as plastics, paper, board, laminates and textiles. Electrostatic attraction or repulsion causes materials to stick to machinery, or to each other, causing jams, slow machine speeds and reduced quality and productivity. Friction, pressure and separation are the major causes of static electricity. When humidity is low, higher static charges are generated .Static becomes more noticeable during winter season, when the air normally dry. Problems caused by static electricity are : Static causes Dust attraction Hazardous sparks or shocks to person Product sticking to itself, rollers or machine parts Materials tearing, jamming or curling Sheet feeding problems Static cling causes handling problem Static problems in coating, slitting & laminating Static cause problem in printing Improper stacking. Remedy to the above Problems To prevent the above one has to either neutralize the static charge or it should be conducted away to the ground. How Static Charge Eliminator Works Eliminator bars which are fixed as near as possible to the material process, on getting supply from the control unit, ionize the surrounding air and because of this, static electric charge is conducted away to the ground. Applications Extruded Tube Film Plant Tape Plant Cutting & Sealing Machine Bag Making-Printing Machine Textile Processing Machine Coating Machine Photographic Film Processing Offset Printing Machine and any other Web converting machine Power Unit Power Control Unit - Can connect upto 3 Nos. Static bars of upto 120 inches working width in the following way:- Top of Film and bottom of film in parallel (Top and bottom side of film) for entry level and one No. bar for end side is necessary. One Control Power unit have provision for connecting three static bar connections. One No. extra spare card is provided inside, so that any one of the connection fails during simultaneous use of all the three, the spare card can be used. After disconnecting the power unit, manually change the static cord from the failed card connection to the spare card connection. To do this, simply open the top cover of the Control Power Unit and change the static cord connection from failed card to the spare card. The power unit comes with one meter length 3 core power cord and static bars comes with two meter single core high power meters special cables as standard length.

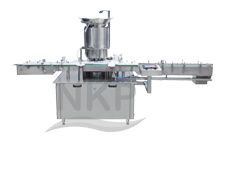

automatic bottle washing machine

230,000 Per Piece

1 Piece (MOQ)

Automatic Bottle Washing Machine Supplier Since the inception of our company, Purvaj Pharma Machinery manufactures and supplies the best quality Automatic Bottle Washing Machine Supplier. Planned according to the industry-laid norms, the offered machine is used to wash the glass bottle in different manufacturing plants. According to the requirements of our patrons, we tender the Automatic Bottle Washing Machine in different specifications. Their high performance and superb washing efficiency make these bottle washing machines highly demand. We also accepted customized orders from the side of customers. Place your order now online for the Automatic Bottle Washing Machine Supplier with us. Contact us now for more information.

Best Deals from Home Appliances

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

400,000 Per piece

1 piece (MOQ)

Input Specification Can accommodate different size of Bottles with the help of change Parts. 10m1 to 1000m1 Bottles Special machines are available for other Size of containers on reques

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

1 Piece(s) (MOQ)

Salient Features : Geneva mechanism. Four inner, one outer and one air wash. Sequence of washes of washes to customer’s choice. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading with two rows.

Fully Automatic Top Loading washing machine

250,000 Per Piece

1 Piece(s) (MOQ)

easy to use computer:fully programmable computer captures all the features for any customized process. The preset programs can be easily modified or erased. Step by step lcd display provides cycle advance, variable time signal & diagnosticauto -reverse digital temperature control. Solenoid operated steam valve.checks. easy to operate. all stainless steel:side plate, outer drum, inner cylinder, doors, chemical dispenser, front, sides, top & back covers all in ss. Side hinged door with inner cylinder. long rust free life.operators safety. pulley positive drive: multi v belts driven on multi groove idler pulleys or through an electric motor pulley with counter unit provide positive drive to the main drive pulley of the inner cylinder. Simple v-belts tensioning device. silent drive. No cylinder speed loss. » horizontal washing machine » horizontal washing machine manufactures » industrial washing machine » industrial washing machine manufactures » laundry machine » laundry machine manufactures » heavy duty washing machine » commercial washing machine » laundry equipment manufacturers » commercial laundry equipments » commercial washing machine manufacturers » dry cleaning machine » industrial top loading washing machine » horizontal top loading washing machine » commercial horizontal laundry machine » commercial top loading washing machine » industrial laundry machine » industries laundry machine » commercial laundry machine » heavy duty laundry machine » commercial laundry machine » semi automatic commercial laundry machine » commercial washing equipment

Industrial Electric Air Filter

999 Per Piece

We are providing our esteemed clients with an excellent quality gamut of Industrial Electric Air Filter. At our well advanced manufacturing unit, our offered electric air filter is manufactured in line with set industry norms by our talented professionals. In addition, our provided electric air filter is made available in huge range of specifications and that can be customized too as per the clients' necessities. Features:-Simple to install,Sturdiness,Rust proof

Cast Iron Filter Press

48,000 Per Piece

1 Piece(s) (MOQ)

Static String

Get Price Quote

Low cost lightweight static eliminator. Tiny conductive micro-fibers provide thousands of conductive points across its surface, which cause the static charge to ionize and flow to ground.

Air Purifier

Get Price Quote

Keep air pollutants at bay with our next-generation air purifiers that work silently and ensure that you and your loved get the freshest and healthiest air possible. Daikin air purifiers come with state-of-the-art features such as streamer discharge technology, dust and odour sensor lamps, plasma dust collection, power-saving inverter, turbo mode and lot more. Its 6-stage filtration process guarantees enhance air cleaning all the time.

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

Salient Features: Total cGMP Model. Total contact parts are of S.S. 316, and other surface parts are of S.S. 304. Geneva Mechanism. Four Inner, one outer and one air wash. Easy loading and unloading with two rows. Higher capacity centrifugal pumps to wash bigger bottles. Loading Unloading Manual. Standard in quality & economical in price.

plastic home appliances

Get Price Quote

Overview We are engaged in offering job work services for Plastic Home Appliances Job Works. All the job work is conducted by a team of skilled and experience professionals. Our entire services are in compliance with set quality standards and guidelines. These services are carried out using advance machines & technologies. We have 4 "Injection moulding machine" with capacity of maximum 250 grms. per one piece. Features: Good Quality Reliable Well finished products

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

Heavy duty base with robust construction off S.S. matt finished body Easy to understand and operate mechanism Suitable for Inner and Outer wash for glass and pet bottle, vial and container The washing machines are designed to clean various types of Glass bottles or Pet bottles, Vials, Ampoules, metal containers either round or odd shaped, subjecting it to a series of distinct processing operations The bottles are easily manually loaded and unloaded on rotating platform and are cleaned in series of operations. Sequence of washes to customer’s choice Solenoid valves are provided to enable the regulation of wash timings and sequence of various washing media to suit specific requirement. Pumps and tanks are mounted on portable stand for easy maintenance and bottle guide system especially for lightweight bottle. Separate panel control to avoid any short circuit due to spraying of water

Automatic Linear Vial Washing Machine

Get Price Quote

Machine manufactured as per cGMP standards. Machine fitted with one set of change parts suitable for 5ml to 30ml vials. Various models available from 60 VPM to 400 VPM. (Please have a look at technical specification column) Machine is suitable for 2ml to 100ml Vial Sizes with the help of minimal change parts. Water recycling arrangement is possible as per requirement. Basic Frame of the Machine totally fabricated from SS-304 materials. All parts coming in contact with washing zone are made from SS 316L materials Machine equipped with safety devices to ensure smooth and silent operation with HIGH rated output. Machine totally rigid and withstands continuous operation for long working hours without any trouble. Washing chamber having various spray zones. Spray duration is electrically controlled by magnetic valve. HIGH pressure spray nozzles entire into the vials during washing time to insure perfect wash of vials. The machine will be provided with SS-316L pumps and SS-316L tanks All contactor and relay from Telemechanic. Main Drive: Gear Motor Make-MGM Varvel Conveyor Drive: Gear Motor Make-MGM Varvel Solenoid Valve from ROTEX Make. Conveyor Belt made from SS 304 Material. Wirewooven Type. All pipe fittings made from SS 316L Materials. The emergency stop button is provided with both ends (In feed & Out feed Side).

Automatic External Vial Washing & Drying Machine

Get Price Quote

We are offering automatic external vial washing & drying machine. Model no. nkew - 100 nkew - 200 direction left to right left to right production rate up to 100 vialsmin. (for 5 ml vial) up to 200 vialsmin. (for 5 ml vial) electrical supply 5.0 hp 5.0 hp power requirement 415 volts, 3 phase (4 wire system), 50 hz 415 volts, 3 phase (4 wire system), 50 hz height of conveyor 900 mm (approx) 900 mm (approx.) dimensions 3400 mm (l) x 915 mm (w) x 1400 mm (h) 3470 mm (l) x 980 mm (w) x 1400 mm (h)

stainless steel home appliances

Get Price Quote

stainless steel home appliances, frypan, Sauce Pan, Pressure Cookers

static electricity eliminator

12,500 Per Piece

Automatic External Vial Washing Machine

Get Price Quote

We are a name to reckon with, when it comes to manufacture Automatic vial washing machines. These machines are flawlessly designed in sync with set industrial norms and standards. These are provided with high grade components and compatible for washing the pharmaceutical vials automatically and promptly. Our proficiency lies in customizing these machines in accordance with clients' specific demands Technical specifications Total cGMP ModelTotal machine Structure is made of S.S. PipeAll Water contract part will be Delrin / food grade materialBottom washing & Drying ensures Vials is cleanedChangeover time will be less then 10minNo Change parts required from 2ml to 100ml VialsMachine can be used for both Powder and Liquid Inject able LineSpecial Design Food grade Conveyor ensures water transfer from conveyor to drain tank, which does not allow water to transfer on drying station�No Vial � No Air/Water� Machine stop systemMachine Stop system�No Water� Machine Stop SystemCabinet door open machine stop systemPLC with touch screen HMISpecial micro Nozzles for bottom drying Properties Tensile strengthDurableSturdy designsLong lastingFlawless performanceCorrosion resistant

static eliminators

Get Price Quote

Belmark Industries is a renowned name in the market. Most of the companies trust us for the supreme quality Static Eliminator. We have grown big as Manufacturers, Exporters & Suppliers of Static Eliminator in the past few years. We owe our popularity to our dedicated staff that strives to develop and manufacture precision engineered Static Eliminator at low cost. Our Static Eliminators are highly durable, offer low cost performance and has longer life. Moreover, it is made available with easy delivery system. Details : Static electricity is a problem faced all over the world. It can affect most industries which handle non-conductive materials such as plastics, paper, board, laminates and textiles. Electrostatic attraction or repulsion causes materials to stick to machinery, or to each other, causing jams, slow machine speeds and reduced quality and productivity. Friction, pressure and separation are the major causes of static electricity. When humidity is low, higher static charges are generated .Static becomes more noticeable during winter season, when the air normally dry. Problems caused by static electricity are : Static causes Dust attraction Hazardous sparks or shocks to person Product sticking to itself, rollers or machine parts Materials tearing, jamming or curling Sheet feeding problems

Steam Air Vaporizer

90 Per unit

Automatic Linear Tunnel type Bottle Washing Machine

Get Price Quote

Automatic Linear Tunnel type Bottle Washing Machine

Get Price Quote

Bottles pushed from Infeed tray and then move on Wiremesh conveyor Belt, which align the Bottle in correct position, to enter into the carrier pocket with help of oscillating guide rails. Oscillating arm deliver the Bottle inside pocket in mouth down position over spraying nozzles. Multijet sprayers fixed at the top cause the total External and Internal surface to be Washed. To avoid any possible cross contamination between two different waters. Each washing station is provided with an independent Circuit. Carrier pocket is moving with indexing motion. When the baskets have completed their motion the needles are lifted. They penetrate the Bottles, Spraying Jets of water or compressed air then Return Down. The baskets movement then advances by one Station. Each station of Bottles passes through the washing cycles selected. The duly washed Bottles then delivered to the Out feed tray with neck opening upward and then automatically re ordered to a next Operation. Salient Features: Machine structure made by SS 304 with argon welded. – SS filter housing & Nozzles made from SS 316. Imported Gear Box, Main Drive and Conveyor. – Infeed Conveyor Belt system. AC Variable Drives for Main drive and conveyor. – Pumps with tank (80 Liter Each) 2 Nos. Special Pocket system ensures easy and trouble free washing of Bottles for outer & inner side. – Water recycling arrangement is possible as per client’s requirement. A special clutch device is available for stoppage of the machine in the event, Bottles is over turned or over diameter. – Machine also equipped with external washing of Bottles. Machine provided with PLC (OPTIONAL) as per customer requirement.

Automatic Linear Vial Washing Machine

300,000 Per UNIT

Automatic Linear Vial Washing Machine – JDM Pharmatech is a renowned name in the world of manufacturing Avant-Garde medical products Pharmaceutical Packaging Machines. Our automatic linear vial washing machine has been engineered to perform with efficacy and ensure thorough cleaning of the surfaces of the vial. This is a completely automatic machine that ensures cleansing of the surfaces of the vial without manual intervention

washing unit

Get Price Quote

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Automatic Linear Vial Washing Machine

Get Price Quote

The Automatic Linear Tunnel type Vial Washing Machines Model VIALWASH-240 is suitable for Round Vials sizes of appx. 5 ml to 30 ml pack size with maximum speed of 240 Vials per minute, Specially designed machine also available for 2 ml Vial Size. Machine construction is in Stainless Steel finish including frame structure. All parts coming in contact with Washing Zone and Jets are made from SS-316 Materials. Intermittent handling of Vials ensures the maximum time for washing and also saves the Water through No Container - No Water system. Machine also offers various customized options for washing sequence as per customers requirements. Washing process takes place with Five different Washing Zones each with 10 nozzles for optimum washing. Machine also equipped with external washing of Bottles.

Electric Steam Iron

Get Price Quote

We are an acclaimed entity, engaged in offering a wide range of Electric Steam Iron. Being a quality-oriented organization, we assure our clients that this product is the best in quality. Our skilled professionals only utilize fine quality raw materials, while manufacturing this steam iron. Moreover, our offered product can be availed in a wide range of sizes and shapes, as per the requirements of our esteemed clients. Features: Rust proof Compact design Optimum quality

Automatic Linear Vial Washing Machine

Get Price Quote

AUTOMATIC LINEAR VIAL WASHING MACHINE, MODEL: HVW-80/150&250 GMP Suitable for washing of Vials (2ml to 30ml) (dia. 14mm to 35mm) All Contact parts made out from SS 316 Entire frame covers & non contact parts made out from SS 304 Needles enter in to the container during washing cycle to meet cGMP requirement Low water consumption Quick change over of parts for other size of containers Complete flexibility with user for washing cycle Machine provides 4 water washes, 3 air washes and 1 silicon (Optional) OPERATION Containers feed from the decartoning station (optional) are received on a unscrambler through Visual Inspection Unit (optional). An infeed worm inverts container as neck down position and feeds them through specially design indexing device. The devicecarry the container forward and stops. Nozzles carrier enters into the container and activates the jet of water/air. The air/water flow is deactivated after the washing cycle is over. Device get indexing for next wash. A separate pumping station (optional) gives the right quantum of water at the desired pressure. In the absence of separate pumping station we can provide the recirculation & siliconising system on request. Washed container are again inverted to neck upward position to collect in trays/directly feed to tunnel.

Static Eliminator

Get Price Quote

Because of the static electric charges depending up on their intensity and surrounding atmosphere, one may see sparking or operator/ worker in surrounding area may get shock. Wherever the material is in the form of film or sheet, it may wrap around the guide rollers causing the breakdown. In printing machine & coating, laminating machine the static may result in fire on solvent based ink which can cause burning of machineries and even loss of human life. In winding process, instead of getting clean winding, one may get crease in winding. Static electric charge also attracts dust particle which gives shabby appearance to the product. Higher the speed of the machine more is the generation of static electric charge resulting into intense problem and if it is not eliminated speed of the machine is to be reduced resulting into production loss. APPLICATIONS Film Plant Extruded Tubing Plant Tape Plant Cutting & Sealing Machine Bag Making-Printing Machine Textile Processing Machine Coating Machine Photographic Film Processing Offset Printing Machine And any other Web converting machine. Laminating Printing and other converting machines

Steam Iron

5,000 Per Piece

1 Piece (MOQ)

Paper Turbine Air Filter

1,000 Per Piece

1 Piece (MOQ)

Static Eliminator

500 - 1,500 Per Sets

Static Eliminator, Roll Wrapping Printing Machine, tension control