SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

180,000 - 200,000 Per Piece

1 Piece (MOQ)

automatic washing machines

Get Price Quote

The range of products which we manufacture and supply to the customers are inclusive of a wide range of Ampoule Washing Machines which are used for different pharmaceutical injectable uses such as sterilizing, sealing, filling and washing and these machines offer a high performance. They have been made using the best technology available in the market and they have been priced at very affordable rates in the market and they are used for cleaning the recycling water tanks. Sturdy Well designed High performance

Best Deals from Home Appliances

automatic bottle washing machine

1,100,000 Per Unit

Automatic Linear Vial Washing Machine

Get Price Quote

Input Specification:- Std. 30m1 to 200m1 Bottles without any major change parts. Can accommodate different size of Bottles with the help of minimal change Parts. Special machines are available for other Size & Type of containers on request.

Hydraulic porta filter

70,000 Per Unit

1 Unit (MOQ)

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

Harsiddh semi-automatic rotary bottle washing machine is designed very compact on vibration free platform for easy operation. We are a leading manufacturer and supplier of wide array of bottle washing machines, which follow GMP norms and used in bottle cleaning process. The bottle washer is made from stainless steel 304 to define rotary platform, flow regulators, bottle holder cups, solenoid valve, pressure meter and specifically designed with Geneva mechanism. Rotary Bottle Washing Machine held specific loading and unloading for easy operation. The panel control system is given separately to avoid electrical disturbances. Stationary nozzles are used to prevent any sort of contamination. The machine can be used for four inner and one outer wash. Our machines have been introduced after in depth research to ensure the containers aseptic and sterilized before filling. Our rotary bottle washers are CE certified. Silent Features Geneva mechanism. Four inner, one outer and one air wash. Sequence of washes of washes to customer’s choice. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading with two rows. Individual solenoid valve for each washing sequence. Pumps and tanks are mounted on parable stand for easy maintenance

Semi Automatic Bottle washing And Filling & Capping Machine

Get Price Quote

Semi Automatic Bottle washing, Filling & Capping Machine The unit is made compact, enclosed in stainless steel elegantly mate mirror finished body. Cam operated Syringes will draw correct volume of liquid and deliver it through tubes to nozzle. Rigid vibration free construction for trouble free performance, S.S.Covers parts for Elegant and easy reach on off switch for total control on operation.

Automatic Linear Type Bottle Washing Machine

850,000 - 2,250,000 Per Piece

1 Piece (MOQ)

Steam Press

Get Price Quote

Our Steam Press is featured with thin soleplate for better heating and provides steam of 15 gram/ minute. We are capable of meeting bulk or urgent requirements effortlessly due to our latest inventory management system and automated management. By this, the stocks are piled up safely to ensure delivery without loss. Only high quality raw materials have been used for the production of our entire range. We check the raw materials against varied quality parameters before procurement.

Automatic Linear Vial Washing Machine

Get Price Quote

The Automatic Linear Vial Washing Machine is excellent for washing injectable glass vials of all varieties. This machine has been integrated with seven washing stations to speed up the regular process of washing with the best approach. This aspect of the machine can be customized based on the requirements of the customer. This Tunnel Type Vial Washing Machine offers four water washes and three air washes. It also offers the most positive and regulated pressurizing washes for vials. All the contact and noncontact parts are made of high quality stainless steel. The details of the variety of the material can be taken from the features that have been enlisted in the following few points. In accordance with the GMP requirements, vials are inverted into a neck down position and the nozzles are entered into vial during the completion of the washing cycles. For sterile vial filling lines, this Vial Washing Machine has proven to be the best solution till now.

Current Transformer Cable Clamp

Get Price Quote

static charge eliminator

8,000 Per Piece 1

Textile industries plastic industries

Cast Iron Cone Fiber Germ Screw Press

100 - 110 Per Piece

02 Piece (MOQ)

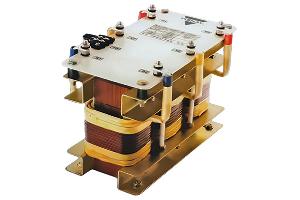

Vishay Harmonic Filter Reactor

Get Price Quote

We make sure that the packaging of products is done using qualitative material in order to deliver the products safely. Only after complete inspection, we deliver the products in the dedicated time span. We ensure; our whole range of products is manufactured utilizing finest grade supplies procured from only leading vendors.Key Benefits Avoidance of Resonance conditions. Tuned & Detuned Harmonic filters. Reduction of Harmonic Distortion (Network clearing) Salient Features High Harmonic loading capability. High Linearity. Low Noise. Low Losses Convenient Mounting. Long Life Time. Technical Data Standards - IEC - 60289/VDE 0532/En61558/ IS - 5553 De-tuning factor p [%] - 7 Effective filter output QC [kVAr] - 5 to 100 Rated voltage VR [V] - 440 Rated frequency [Hz] - 50 Ambient temperature / Insulation class - 40oC / Class-F Temperature protection (NC) - Yes Duty Cycle (Irms) - 100%

Automatic Linear Vial Washing Machine

Get Price Quote

Harsiddh engineering Co. is a recognized brand in the supply vial washing machines. The two popular automatic linear vial washing machines are the HLVW-150 and the HLVW-80 model. The HLVW- 150 has a throughput of 60-150 vials per minute while the HLVW-80 model has capacity of 40 to 80 vials per minute depending on vial size that ranges from 2ml to 20ml. Our vial washing machine has CE certification.The loading, cleaning and exit mechanisms are automatic and this increases the cleaning throughput and ensures minimum handling and contamination. The machines have a specially designed in-feed worm wheel that inverts vials and holds them on an indexing device ready for the first wash. The washing cycle is achieved through water and air nozzles that are directed on the inverted vials for maximum cleaning. The specially designed pumps supply water to nozzles at high pressure to effect the cleaning.

Automatic Vial External Washing Machine

Get Price Quote

Automatic Linear Vial Washing Machine

Get Price Quote

AUTOMATIC LINEAR DOUBLE TRACKS VIAL WASHING MACHINE MODEL : AHVW 120, AHVW 60 Operations: • The vial trays are directly un-loaded to the vial tray from which vials directly transfer to the turn-table. • The turn table slowly transfer vials to the linear washing machine in single track or two tracks feed warm, from where vials are automatically come in to invert position. • The synchronized star- wheel places two vials at a time in two tracks indexing chain or one vials in to the single track machine. • The indexing chain positively carries inverted pair of vials through seven sequential washes. • At the end of washing operation vials are re-inverted back into original and collected in the tray. Pumping station: Tank with valve – 3 NOS. SS 316 pump – 3 NOS. S.S. Filter housings and filter cartridges. Change parts: Change over of each vial size contain star wheels, worms, inverters./div> Technical specifications: SS finish gmp model Dimension: 1600mm l >< 800mm w>< 800mm h Electrical: single phase Output: 3000- 4000 vials per hours in case single track machine 6000- 8000 vials per hours in case double track machine

Automatic Rotary Bottle Washing Machine

Get Price Quote

Air Purifier

5,500 Per Piece

Automatic Beer Bottle Washing Machine

Get Price Quote