SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

250,000 - 375,000 Per Piece

1 Piece (MOQ)

Automatic Linear Bottle Washing Machine

Get Price Quote

Automatic Linear Bottle Washing Machine is suitable to wash glass bottles. Machine equipped with six washing stations can be interchangeable as per specific customer’s requirements. This Linear Bottle Washer provides 3 water wash & 3 air wash for positive & pressurizing washes of bottles. All contact parts made from stainless steel 316 and non-contact parts made from stainless steel 304 materials. Bottle invert into neck down position and nozzles enters into bottle during washing cycle to meet GMP requirements. Automatic Linear Bottle Washing Machine is ideal and economic choice for online Sterile Vial Filling Line. Machine is having uses in Pharmaceutical, Cosmetic, Food, Chemical & allied industries. Salient Features A complete cGMP model All contact parts are made from high quality Stainless Steel 316L and argon arc welded All exposed parts are made from Stainless Steel 304/hard chrome plated/brass for corrosion free long life. The unit built on S.S. Square pipe frame and totally encompassed with S.S. Coverings Washing section is totally covered with acrylic cabinet. No Container - No Washing” system. No washing - No water supply” system. Quick change over with minimum use of tools. Variable AC frequency drive for speed adjustment. Low water consumption. Digital counter for counting production output. Fixed top nozzles at each washing station ensures external washing of vials/bottles at the same time of internal washing. Flow of washing Medias stop during the indexing of chain saves utilities. Easily cleanable & Inter changing facility. Process Operation Containers feed from the de-cartooning station are received on an In feed turn table. An in feed worm inverts container to neck down position and feeds them through a specially designed indexing device. The device carries the container forward and stops. Nozzles carrier enters into the container and activities the jet of water/air. The air/water flow is deactivated after the washing cycle is over. Device indexes the vials/bottles for next wash. A separate pumping station gives the right quantum of water at the desired pressure. Washed containers are again inverted to neck upward position to collect in out-feed tray/directly feed to tunnel. Washing Cycle 1st washRecycled Water 2nd washPurified Air 3rd washDM water 4th washDM water 5th washPurified Air 6th washDistilled Water (WFI)

Best Deals from Home Appliances

Steam Press

Get Price Quote

Our Steam Press is featured with thin soleplate for better heating and provides steam of 15 gram/ minute. We are capable of meeting bulk or urgent requirements effortlessly due to our latest inventory management system and automated management. By this, the stocks are piled up safely to ensure delivery without loss. Only high quality raw materials have been used for the production of our entire range. We check the raw materials against varied quality parameters before procurement.

Automatic External Vial Washing Machine

Get Price Quote

The External Vial Washing Machine is designed to wash the outer surface of round shaped Vials [5ml to 100ml Vials]. This machine washes the outer sides of Vials and eliminates the particles that are formed on the vials, which are previously filled and sealed. Vial external washer machine is fitted with after capper machine is injectable vial external washer machine / injection vial external washer machine, oncology vial external washer machine and aseptic processing lines, speed up to 120vpm , vial surfaces involves the destruction or removal of any possible product residual so as to prevent them infecting the operators and cross contamination between containers and machine, as well. From the infeed Turn Table the vials are fed into the External Vial Washing Machine conveyors. The machine consists of two conveyors on which the vials are properly fed and transported from in feed Turn Table for the washing operation. Two operations are carried out on this machine. First the vials are washed by water jet and then dried by air jet. On the sides of the conveyor a set of spray nozzles are fitted on each conveyor for water jet. One set of knifes blocks are provided on each conveyor for air jet The air is sprayed through this knifes. The Knifes are fitted in a inclined manner which ensures that the air that is sprayed reaches each corner of the vial which are previously washed. After washing and drying the vials are guided to the outfeed Turn Table. Before reaching the outfeed Turn Table a special arrangement is provided to dry the vial from the bottom side. A set of syringes are provided on the sides of each conveyor at the exit end which sprays the air jet on the bottom part of the vial resulting in the drying of the vials This machine is completely operated by PLC. A covering of Acrylic cabinet is provided in the machine which when opened up during the operation immediately stops the supply of water & air and shows the indication with alarm in the PLC.

static charge eliminator

8,000 Per Piece 1

Textile industries plastic industries

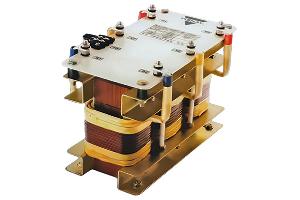

Vishay Harmonic Filter Reactor

Get Price Quote

We make sure that the packaging of products is done using qualitative material in order to deliver the products safely. Only after complete inspection, we deliver the products in the dedicated time span. We ensure; our whole range of products is manufactured utilizing finest grade supplies procured from only leading vendors.Key Benefits Avoidance of Resonance conditions. Tuned & Detuned Harmonic filters. Reduction of Harmonic Distortion (Network clearing) Salient Features High Harmonic loading capability. High Linearity. Low Noise. Low Losses Convenient Mounting. Long Life Time. Technical Data Standards - IEC - 60289/VDE 0532/En61558/ IS - 5553 De-tuning factor p [%] - 7 Effective filter output QC [kVAr] - 5 to 100 Rated voltage VR [V] - 440 Rated frequency [Hz] - 50 Ambient temperature / Insulation class - 40oC / Class-F Temperature protection (NC) - Yes Duty Cycle (Irms) - 100%

Automatic Linear Tunnel type Bottle Washing Machine

800,000 - 2,000,000 Per Piece

1 Piece (MOQ)

The premium quality Automatic Linear Tunnel Type Bottle Washing Machine comprises the main structure, bottle holding pocket, in-feed tray, out-feed wire mesh conveyor, washing nozzle, PLC & HMI, electrical panel, motor, pumps with tank & AC drives. Salient Features Safety devices to ensure smooth and silent operation Efficient Flawless functioning Durable Application Cleaning and washing of Bottles Industry Pharmaceutical FMCG Food processing Beverages

Cast Iron Cone Fiber Germ Screw Press

100 - 110 Per Piece

02 Piece (MOQ)

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

1 Piece(s) (MOQ)

Salient Features : Geneva mechanism. Four inner, one outer and one air wash. Sequence of washes of washes to customer’s choice. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading with two rows.

Automatic External Vial Washing Machine

Get Price Quote

We are the main supplier of this product.

Automatic Linear Vial Washing Machine

Get Price Quote

description automatic linear vial washing machine is suitable to wash injectable glass vials. Machine equipped with seven washing stations can be interchangeable as per specific customer’s requirements. This linear vial washer provides 4 water wash & 3 air wash for positive & pressurizing washes of vials. All contact parts made from aisi ss 316l and non-contact parts from aisi ss 304 materials. Vials invert into neck down position and nozzles enters into vial during washing cycle to meet gmp requirements. Automatic linear vial washing machine is ideal and economic choice for online sterile vial filling line. salient features a complete cgmp model all contact parts made from s.s. 316l entire frame covers & non contact parts made out from ss 304 easy cleanable & inter changing facility machine provides 4 water washers & 3 air washers complete flexibility with user for washing cycle feeding online vial transferring chain through turn table "no vial - no washing” system “no washing - no water supply” system nozzles enter into the container during washing cycle to meet cgmp requirement low water consumption quick change over with minimum use of tools microprocessor based variable ac frequency drive for speed control vial counter for counting the final production output process operation containers feed from the de-cartooning station are received on an infeed turn table through visual inspection unit. An in feed worm inverts container to neck down position and feeds them through a specially designed indexing device. The device carries the container forward and stops. Nozzles carrier enters into the container and activities the jet of water/air. The air/water flow is deactivated after the washing cycle is over. Device indexes the vials for next wash. A separate pumping station gives the right quantum of water at the desired pressure. Washed containers are again inverted to neck upward position to collect in trays or directly feed to sterilizing tunnel.

Robot Vacuum Cleaner

9,000 Per Piece

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

DESCRIPTION Harsiddh semi-automatic rotary bottle washing machine is designed very compact on vibration free platform for easy operation. We are a leading manufacturer and supplier of wide array of bottle washing machines, which follow GMP norms and used in bottle cleaning process. The bottle washer is made from stainless steel 304 to define rotary platform, flow regulators, bottle holder cups, solenoid valve, pressure meter and specifically designed with Geneva mechanism. Rotary Bottle Washing Machine held specific loading and unloading for easy operation. The panel control system is given separately to avoid electrical disturbances. Stationary nozzles are used to prevent any sort of contamination. The machine can be used for four inner and one outer wash. Our machines have been introduced after in depth research to ensure the containers aseptic and sterilized before filling. Our rotary bottle washers are CE certified. SALIENT FEATURES Geneva mechanism. Four inner, one outer and one air wash. Sequence of washes of washes to customer’s choice. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading with two rows. Individual solenoid valve for each washing sequence. Pumps and tanks are mounted on parable stand for easy maintenance. TECHNICAL SPECIFICATION Production Rate 60 to 100 Containers/Min. Input Specification Container Dia.: 25mm to 100mmContainer Height: Up to 280mm Power Specification 1 H.P., 3 Phase, 4 Wire System, 50 Hz Optional Accessories 2 Pumps – Pumping StationElectric Heater Tank Utility Fresh Water: 900 Liters/HourDM Water 300 Liters/ HoursAir 30 CFM @ 5 bar (5 Wash) Overall Dimension 1550 mm (L) X 1700 mm (W) X 1300 mm (H) Net Weight: 750 Kgs. Gross Weight: 1000 Kgs.

Semi Automatic Bottle washing And Filling & Capping Machine

Get Price Quote

Semi Automatic Bottle washing, Filling & Capping Machine The unit is made compact, enclosed in stainless steel elegantly mate mirror finished body. Cam operated Syringes will draw correct volume of liquid and deliver it through tubes to nozzle. Rigid vibration free construction for trouble free performance, S.S.Covers parts for Elegant and easy reach on off switch for total control on operation.

Automatic Linear Tunnel type Vial Washing Machine

Get Price Quote

Application: Our Machine suitable for Pharmaceuticals, Dairy, Distilleries & Breweries, Cosmetics & Food & Ancillaries Industries etc. Description: ‘Bhagwati High Speed Linear Vial Washing Machine is used for washing of Vials and finds wide application in Pharmaceuticals Industries. The automatic loading arrangement facilities loading of Vials on to SS wire mesh conveyor through feed conveyor or Vials are pushed manually from feed table. This saves manpower as Vials are feed into pockets automatically. The automatic unloading mechanism consists of unloading Vial continues on to turn table (Optional). Operation: Vials will be pushed from in feed tray and then move on wire woven conveyor belt, which align the Vial in correct position, to enter in to the carrier pocket with help of oscillating guide rails. Oscillating arm deliver the Vial inside pocket in mouth down position over spraying nozzles. Multijet sprayers fixed at the top cause the total external and internal surface to be washed. To avoid any possible cross contamination between two different waters. Each washing station is provided with an independent circuit. Carrier pocket is moving with indexing motion. When the baskets have completed their motion the needles are lifted. They penetrate the Vials, spraying jets of water or compressed air then return down. The baskets movement then advances by one station. Each station of Vials passes through the washing cycles selected. The duly washed Vials then delivered to the out feed tray with neck opening upward and then automatically re ordered to a drying and sterilizing tunnel with back pressure.Salient Features: Special Pocket system ensures easy and trouble free washing of Vials from outer and inner side. Indexing motion makes easier for syringes to move inside Vial, when it is in stationery motion. No Change parts are required from 2 ml to 100 ml Vial. (Change parts are required 2 ml & 50,100 ml Vials) Washing cycles can be adjusted as per customer requirement. User friendly machine, even semi skilled operator can operate the machine very easily. A Special clutch device is incorporated for Stoppage of Machine in the event; Vial is over turned or over diameter. Low RPM but High out/put. Imported Gear Motor for +Main drive and conveyor. A.C. Frequency drives for Main drive and conveyor. Pumps with tank (60 litres each) 3 nos. In feed conveyor belt system. Suitable for 2 ml to 100 ml (. (Change parts are required 2 ml & 50,100 ml Vials) S.S. cGMP Model. S.S. 304 Frame Structure. Suitable for 2ml to 100ml at Output Speed of 40 to 120 Vials/Min. Imported Gear Box for Main Drive & Conveyor Drive. All contact parts will be of S.S. 316 material In feed Wire Woven Belt for feeding of Vials. HDPE material Vial pockets. Grand force Pump having S.S. 316 contact surface – 3 Nos. 10 Nos. Different Washing Stations and can change as per customer requirement. Outer wash of Air & Water both. Loading & Unloading of Vials will be through mechanical Cams. S.S. Filter Housing for Water & Air and machine consist of 3 Nos. Water Filter & 1 No. Air Filter Water Filter & Air Filter will be supplied with Nylon Cartage. Recalculated Water Filter will be of 10 Micron. D.M. & W.F.I. Water Filter will be of 5 Micron. Air Filter will be of 0.22 Micron. Total 40 Rows & each Row is having 12 Pockets. Total No. of Pockets is: 480 Nos.

Air Purifier

5,500 Per Piece

Automatic External Ampoule Washing machine

Get Price Quote

AUTOMATIC EXTERNAL/OUTER AMPOULES-VIALS WASHING MACHINES MODEL :AHEW 200 OPERATION: The Automatic External Vial Washing Machine is suitable for Round Ampoules/Vials sizes of appx. 1ml to 20 ml size with maximum speed of 200 Ampoules Vials per minute Entire Machine construction is in Stainless Steel finish including ss frame body. All parts coming in contact with water are made from SS-316 L Materials. Continues travelling of Vials on rotary station ensure the washing of each Ampoules vials from top as well as side. We offer Machine with customised options of end user for washing sequence as per customers requirements. SALIENT FEATURES : • 6 Jets for 2 washing zones • All contact parts made of SS-316 material • Machine construction in SS-304 material • Suitable for 2 ml to 3oml Vial Size with help of change parts • Washing sequence can be made as per customers requirements. • Built-in 2 ss 316 water Pumps, 1hp blower and 1 ss 316 materials Tanks • Direct In-feed of Ampoules vials from hopper/Turn Table and Exit of Ampoules Vials to connect with Ampoules or vials sticker labelling machine

cast iron lamp post

5,000 Per unit

Cast Iron lamp pole.

Paper Turbine Air Filter

1,000 Per Piece

1 Piece (MOQ)

automatic bottle washing machine

1,100,000 Per Unit

automatic washing machines

Get Price Quote

The range of products which we manufacture and supply to the customers are inclusive of a wide range of Ampoule Washing Machines which are used for different pharmaceutical injectable uses such as sterilizing, sealing, filling and washing and these machines offer a high performance. They have been made using the best technology available in the market and they have been priced at very affordable rates in the market and they are used for cleaning the recycling water tanks. Sturdy Well designed High performance

Electric Steam Iron

Get Price Quote

We are an acclaimed entity, engaged in offering a wide range of Electric Steam Iron. Being a quality-oriented organization, we assure our clients that this product is the best in quality. Our skilled professionals only utilize fine quality raw materials, while manufacturing this steam iron. Moreover, our offered product can be availed in a wide range of sizes and shapes, as per the requirements of our esteemed clients. Features: Rust proof Compact design Optimum quality

Automatic Linear Vial Washing Machine

Get Price Quote

Input Specification:- Std. 30m1 to 200m1 Bottles without any major change parts. Can accommodate different size of Bottles with the help of minimal change Parts. Special machines are available for other Size & Type of containers on request.

static charge eliminator

Get Price Quote

Leading Manufacturer of Static Charge Eliminator such as High Voltage Static Charge Eliminator and Handheld Static Charge Eliminator from Ahmedabad. Riding on unfathomable volumes of industrial expertise, we are engaged in manufacturing a broad assortment of Handheld Static Charge Eliminator. Features: * Negligible maintenance* Compact design* Corrosion resistance

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

Get Price Quote

Harsiddh semi-automatic rotary bottle washing machine is designed very compact on vibration free platform for easy operation. We are a leading manufacturer and supplier of wide array of bottle washing machines, which follow GMP norms and used in bottle cleaning process. The bottle washer is made from stainless steel 304 to define rotary platform, flow regulators, bottle holder cups, solenoid valve, pressure meter and specifically designed with Geneva mechanism. Rotary Bottle Washing Machine held specific loading and unloading for easy operation. The panel control system is given separately to avoid electrical disturbances. Stationary nozzles are used to prevent any sort of contamination. The machine can be used for four inner and one outer wash. Our machines have been introduced after in depth research to ensure the containers aseptic and sterilized before filling. Our rotary bottle washers are CE certified. Silent Features Geneva mechanism. Four inner, one outer and one air wash. Sequence of washes of washes to customer’s choice. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading with two rows. Individual solenoid valve for each washing sequence. Pumps and tanks are mounted on parable stand for easy maintenance

Hydraulic porta filter

70,000 Per Unit

1 Unit (MOQ)

Steam Air Vaporizer

90 Per unit

Current Transformer Cable Clamp

Get Price Quote

houseware appliances

Get Price Quote

houseware appliances, SS Kitchenware

energy saving active harmonic filters

Get Price Quote

energy saving active harmonic filters, process, Electronic Control Panel