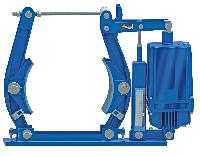

hydraulic thruster brake

Get Price Quote

For keeping the quality of the products intact, our quality experts check all levels including procurement of raw materials, production, packaging and dispatch. Based in Gujarat(India), we hold specialization in offering quality products that are the perfect outcome of premium material and modern manufacturing techniques.

hydraulic thruster brake

Get Price Quote

A thruster shoe brake has a pair of cast iron shoes which are lined up with friction pads. The shoes are hinged on main arm and side arm of the brake, each of them have a hinge pin fitted in the base. They are connected to each other on top by a tie rod, which is hinged in the main arm and locked to the swivel block in the side arm, by a lock nut. A crank lever is hinged on the main arm and the other end is fixed to the top clevis of the thruster by a hinge pin. A brake spring is fixed on the main arm and is pre-loaded by a locknut on the lever. The pre-tension in this spring decides the braking torque. The thruster is fitted on the base by a hinge pin. When the thruster is not energized, the brake shoes are pressed on the brake drum fitted on the drive motor shaft and hold it under the effect of braking force provided by the spring. In such condition, the brake is applied and the drum cannot rotate. As the piston travels upwards the angle lever turns, pushes the brake rod and compresses the brake spring. Simultaneously, the brake lever on the other side of the wheel (Brake Drum) is retracted. When the first lever reaches the stop on the brake base member the brake lever at the thruster begins to move, releasing the brake drum. Technical Specification

Best Deals from Hydraulic Brakes

hydraulic thruster brake

7,000 - 40,000 Per Piece

Hydraulic Press Brakes

Get Price Quote

SALIENT DESIGN FEATURES Mono block of welded steel frame of ultra tested 2062 steel plates rigid to provide accurate bending. All pivots are hardened of ground pin bushes of lubricated by a central hand pump. Repetitive accuracy is within ± 0.03 mm ram travel parallelism without using sensitive and complex servo hydraulics. Most reliable hydraulic components and sealings of international reputed design for 350 bar against operating pressure of 160 bar maximum. Three cycles of operation inch, single cycle and auto for greater operator convenience. Movable operator console is provided with switches for cycle selection, ram up-down travel, emergency stop and motor on / off. Front operated manual back gauge. Electrical panels and components are provided as per international reputed brands. Precisely panels and manufactured cylinders provide unlimited trouble free working life. Seals can be changed quickly without dismantling the ram or need of crane. STANDARD FEATURE ACCESSORIES Main drive motor of standard make. Electrical control panel with three speeds inch, single cycle and auto mode of operation. Two front sheet supports. Front operated manual back gauge. Pair of lifting links. Fine stroke adjustment rod with limit switches. One suitable 5 way die and blade. (Segmented or full length, EN-9, Not covered under warrantee) Movable console with emergency stop. Tonnage indicating adjustment device. Manual centralized lubrication system with a hand pump. Bending Chart. OPTIONAL ACCESSORIES NC Back Gauge Motorized Back Gauge with D.R.O. Finger for standard Back Gauge Automatic Lubrication System.

hydraulic thruster brakes

11,000 Per Units

Hydraulic Press Brake

Get Price Quote

Hydraulic Press Brake, CNC Turning Machining Job Work

Electro.Hydraulic Thruster Brake

Get Price Quote

Electro.Hydraulic Thruster Brake, Double Girder Goliath Cranes

Hydraulic Press Brakes

Get Price Quote

Hydraulic Press Brakes, angle notching machines, special purpose machinery

Hydraulic Press Brake

Get Price Quote

Hydraulic Press Brake, Hydraulic Variable Rake Angle Shears