hydraulic brake

20,350 Per Piece

hydraulic thruster brake

7,000 - 40,000 Per Piece

Best Deals from Hydraulic Brakes

Sytco Hydraulic Brake

2,000 - 30,000 Per No

1 Piece (MOQ)

Hydraulic Press Brakes

300,000 Per piece

1 Nos (MOQ)

We are manufacturer of Hydraulic Press Brake.

Hydraulic Press Brakes

Get Price Quote

Capacities from 200 T to 1000 T. Conventional CNC controls can be offered. Fabricated steel structure fully stress relieved.Hydraulic elements of reputed make.

Hydraulic Press Brakes

980,000 - 4,500,000 Per nos

Nc Hydraulic Press Brake

Get Price Quote

NC hydraulic Press brakes are economical and very reliable solution for industry demand. NC hydraulic press brakes are designed to give more accuracy and better productivity. The controller has a facility to program the various jobs with complex bending sequence on screen.The Numeric Control is used for Two Axis Control,1. Ram Axis Y 2. Back Gauge Axis X.The program gives facility to bend different bending degrees; different back gauge positions & different open positions. It has a facility to save different programs and same can be reloaded as & when required. The back gauge consists of Flip-top Fingers, Ball Screw & Linear Bearing along with drive. Product Features It has a facility to program the variegated jobs includes complex bending sequence. This facility helps to perform complicated bending job in a signal setting and repeatable production. Dedicated controller with LCD monochrome screen & numeric keypad. Bend angle & Depth Mode program. 128 Programs x 16 bends per program can be stored. Stroke control and stroke counter on screen. Highly Precise press brake scale for accurate Y- axis positioning. AC Servo drive for back gauge positioning. Hardened ground Balls screwand linear motion bearing for better position accuracy and longer life. Ram tilting to maintain banding accuracy over period.

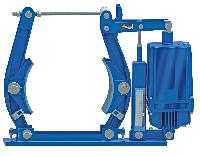

Electro Hydraulic Thrustor Brakes

Get Price Quote

We are offering electro hydraulic thrustor brakes. Electro hydraulic thrustor: thruster brake is a device used to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoes by a pre-stressed comprising spring. The shoes press on the rotating brake drum retarding its speed and finally stop it. The releasing of the.

Nc Hydraulic Press Brake

Get Price Quote

NC hydraulic Press brakes are economical and very reliable solution for industry demand. NC hydraulic press brakes are designed to give more accuracy and better productivity. The controller has a facility to program the various jobs with complex bending sequence on screen.The Numeric Control is used for Two Axis Control,1. Ram Axis Y 2. Back Gauge Axis X.The program gives facility to bend different bending degrees; different back gauge positions & different open positions. It has a facility to save different programs and same can be reloaded as & when required. The back gauge consists of Flip-top Fingers, Ball Screw & Linear Bearing along with drive. Product Features It has a facility to program the variegated jobs includes complex bending sequence. This facility helps to perform complicated bending job in a signal setting and repeatable production. Dedicated controller with LCD monochrome screen & numeric keypad. Bend angle & Depth Mode program. 128 Programs x 16 bends per program can be stored. Stroke control and stroke counter on screen. Highly Precise press brake scale for accurate Y- axis positioning. AC Servo drive for back gauge positioning. Hardened ground Balls screwand linear motion bearing for better position accuracy and longer life. Ram tilting to maintain banding accuracy over period.

Nc Hydraulic Press Brake

600,000 Per Set

WE are manufacturer of Hydraulic Press Brake machine and shearing machine all Models are available like Manual Hydraulic Press Brake, NC press brake, cnc press brake, hydraulic shearing machine, NC hydraulic shearing machine

Hydraulic Press Brakes

Get Price Quote

Technik series hydraulic press brake ton capacity from : 20 to 400 ton length : 1500 to 4000mm accurate & precise machine for your toolroom.

Hydraulic Press Brakes

1,200,000 Per piece

Hydraulic Press Brake

Get Price Quote

Bhavya Machine Tools offers hydraulic press brake. It is mainly useful for bending metal sheets and plates. These tools are made using top grade materials.

nc hydraulic press brakes

Get Price Quote

Short Facts: Fitted with 2 Axes NC controller i.e., provided with NC stroke & NC back guage which offers better economy evers for multiple bend jobs. Setting for regular jobs can be stored in memory to save time. Allows air bending of different angles by memorizing stroke positions. Enables operator to bend jobs with 1 to 4 bends on each edge in one set up, reducing handling time, inventory of semi-finished jobs & work-in-progress costs. Offers reduced set-up, fastest stroke cycles for all jobs, minimizes the need to refer drawings for repeat runs. Back guage retraction on pinch point. NC controllers & drives: The controller memorizes 792(=8 bends per program * 99 programs) stroke positions to store most popular bends, stroke length, stores height of 10 pairs of punches & dies to avoid faulty programming & allows skipping a step in program if the bend is not required on the job. The controller can be connected directly to computer via RS232 serial for data backup.

Hydraulic Press Brake

Get Price Quote

Hydraulic Press Brake Manufacturers & Suppliers We are widely known manufacturers, Suppliers, Exporters, Distributors and providers of Hydraulic Press Brake. That can help you keep operational prices as low as potential. Our Standard and Optional features make it easier, better, durable, & more efficient. We can deliver it to client at a considerable rate. Design Features Accurate right angle welded steel frame with tested material gives accurate bending. Five piece guide sliding device for accurate vertical movement of RAM. Adjustable Pressure Relief/Controlling Valve for HT material. Use of hardened pin and bushes gives less maintenance. Flexible sheet support for longer and heavier plates/sheets. Emergency stop push switch with moveable console including motor on/off, RAM up/ down & cycle selection switch. Centrally lubrication system by Hand pump at all pin, bushes and joints. Accurately Synchronized cylinders for equally vertical force of RAM at full length. Five way V- Block in one and suitable Blade. Fine stroke adjustment Rod with limit switches Indication light (Tower Light) with safety alarm sound Standard Accessories Including Machine Pair of Blade & Bloke installed with machine. Operator Console & Foot switch for easier operation. Sheet support. Flexible sheet support for longer and heavier plates/sheets. Technical Features Bending Length: 1500/2000/2500/3000/4000 Thickness: Up to 4mm / 6mm / 8mm / 10mm / 12mm / 16mm / 20mm. ACCURCY: ± 0.03MM Back Gauge Length: 250mm Manual Back Gauge: 600mm / 1000mm N C Back Gauge

Hydraulic Thrustor Brake

Get Price Quote

Thruster brake is a device used to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoes by a pre-stressed comprising spring. The shoes press on the rotating brake drum retarding its speed and finally stop it. The releasing of the brake drum and compressing of the spring is done by thruster. Feature-- Rugged design Consistent braking performance Robust in construction Long life Trouble free maintenance Easy in service

Hydraulic Press Brake

450,000 Per Piece

hydraulic thruster brakes

11,000 Per Units

hydraulic thruster brake

Get Price Quote

A thruster shoe brake has a pair of cast iron shoes which are lined up with friction pads. The shoes are hinged on main arm and side arm of the brake, each of them have a hinge pin fitted in the base. They are connected to each other on top by a tie rod, which is hinged in the main arm and locked to the swivel block in the side arm, by a lock nut. A crank lever is hinged on the main arm and the other end is fixed to the top clevis of the thruster by a hinge pin. A brake spring is fixed on the main arm and is pre-loaded by a locknut on the lever. The pre-tension in this spring decides the braking torque. The thruster is fitted on the base by a hinge pin. When the thruster is not energized, the brake shoes are pressed on the brake drum fitted on the drive motor shaft and hold it under the effect of braking force provided by the spring. In such condition, the brake is applied and the drum cannot rotate. As the piston travels upwards the angle lever turns, pushes the brake rod and compresses the brake spring. Simultaneously, the brake lever on the other side of the wheel (Brake Drum) is retracted. When the first lever reaches the stop on the brake base member the brake lever at the thruster begins to move, releasing the brake drum. Technical Specification

Hydraulic Press Brake

Get Price Quote

Bhavya Machine Tools offers hydraulic press brake. It is mainly useful for bending metal sheets and plates. These tools are made using top grade materials.

Hydraulic Press Brakes

Get Price Quote

SALIENT DESIGN FEATURES Mono block of welded steel frame of ultra tested 2062 steel plates rigid to provide accurate bending. All pivots are hardened of ground pin bushes of lubricated by a central hand pump. Repetitive accuracy is within ± 0.03 mm ram travel parallelism without using sensitive and complex servo hydraulics. Most reliable hydraulic components and sealings of international reputed design for 350 bar against operating pressure of 160 bar maximum. Three cycles of operation inch, single cycle and auto for greater operator convenience. Movable operator console is provided with switches for cycle selection, ram up-down travel, emergency stop and motor on / off. Front operated manual back gauge. Electrical panels and components are provided as per international reputed brands. Precisely panels and manufactured cylinders provide unlimited trouble free working life. Seals can be changed quickly without dismantling the ram or need of crane. STANDARD FEATURE ACCESSORIES Main drive motor of standard make. Electrical control panel with three speeds inch, single cycle and auto mode of operation. Two front sheet supports. Front operated manual back gauge. Pair of lifting links. Fine stroke adjustment rod with limit switches. One suitable 5 way die and blade. (Segmented or full length, EN-9, Not covered under warrantee) Movable console with emergency stop. Tonnage indicating adjustment device. Manual centralized lubrication system with a hand pump. Bending Chart. OPTIONAL ACCESSORIES NC Back Gauge Motorized Back Gauge with D.R.O. Finger for standard Back Gauge Automatic Lubrication System.

hydraulic thruster brake

Get Price Quote

For keeping the quality of the products intact, our quality experts check all levels including procurement of raw materials, production, packaging and dispatch. Based in Gujarat(India), we hold specialization in offering quality products that are the perfect outcome of premium material and modern manufacturing techniques.

CNC Hydraulic Press Brake

Get Price Quote

Manufactured using qualitative raw material, Our organization is prominent manufacturers of CNC Hydraulic Press Brake, which is appreciated for simple operation and provide maximum output.

press brake

Get Price Quote

NC hydraulic Press brakes are economical and very reliable solution for industry demand. NC hydraulic press brakes are designed to give more accuracy and better productivity. The controller has a facility to program the various jobs with complex bending sequence on screen. The Numeric Control is used for Two Axis Control, 1. Ram Axis Y 2. Back Gauge Axis X. The program gives facility to bend different bending degrees; different back gauge positions & different open positions. It has a facility to save different programs and same can be reloaded as & when required. The back gauge consists of Flip-top Fingers, Ball Screw & Linear Bearing along with drive. Range: 20MT to 600MT | Length: 1250 mm to 7000 mm

Hydraulic Press Brake

Get Price Quote

Hydraulic Press Brakes

Get Price Quote

we are offering the hydraulic press brake by us is manufactured with sophisticated machines and equipment. made using high-grade raw material and components, these presses are acclaimed for their easy installation.

Hydraulic Press Brake

Get Price Quote

It is featured with the latest mechanisms to make sheet metal operations more flexible and versatile. This equipment works with hydraulic cylinders which are provisioned at the rear side and are fixed to brining out harmonization between the machining table and ram. The machine is structured with heavy duty steel body that provides shock resistant capacity at times of handling heavy duty cutting or bending operations and when the work gets overloaded. Our hydraulic press brake is composed of premier quality of components therefore performance and usage on long run will remain undoubtedly precise. Visit our website to know more about the wide range of standard and optional accessories that is available for this apparatus. Steel welded structure, stress elimination by vibration, high mechanical strength, and exceptional rigidity Ram stroke hydraulic approaching downward, stable and reliable Mechanical stop and steel torsion bar to maintain synchronization and high precision Electrical adjustment, manual fine adjustment and digital display for background and ram stroke wedge compensation on top punch clamp slice

Hydraulic Press Brake

Get Price Quote

Standard Supply: Main Drive Motors Standard 'v' Block Pair of Foot Swishers Electric Control Panel "INCH" & "SINGLE CYCLE", "DOUBLE CYCLE","AUTO" mode of Operation Fine Stroke adjustments Rod with Limit Switches. Machine Capacity (MS) 1 mm to 1.6 mm 3.25 mm 5 mm 6 mm 8 mm 10 mm Machine Length 1500mm to 3050mm Length

Hydraulic Press Brake

400,000 Per Piece

Nc Hydraulic Press Brake

Get Price Quote

NC Hydraulic Brake Press Machine NC Hydraulic Press Brake is an electro-hydraulic synchronized double-cylinder NC Sheet Bending Machine. The bending principle is similar to the angle forming principle of common Brake Press. It can bend different work pieces according to different angles of molds. The NC system controls the electro-hydraulic ratio direction valve. NC ress brake can realize bending depth full closed-loop digital control through the grating feedback. NC hydraulic press brakes can simply be summed up as a sheet bending machine that controls positioning system, block bending depth and automatic compensation for workbench deformation through NC system. NC Hydraulic Press Brakes are designed and developed through years of experience in Sheet Metal Working Machinery. Our NC Press Brakes are developed as per the latest trends in the industry. Hydraulic NC Press Brakes are fitted with 2 Axes NC controller i.e., provided with NC stroke & NC back guage which offers better economy ever for multiple bend jobs. Setting for regular jobs can be stored in memory to save time. Allows air bending of different angles by memorizing stroke positions. Request a quote to get the best NC Hydraulic Press Brake Price Features : Hydraulic NC Press Brake Machine Facility to program the variegated jobs includes complex bending sequence. This perform complicated bending job in a signal setting. Dedicated controller with LCD monochrome screen & numeric keypad. Bend angle & Depth Mode program. 128 Programs x 16 bends per program can be stored. Stroke control and stroke counter on screen. Highly Precise press brake scale for accurate Y- axis positioning. AC Servo drive for back gauge positioning. Hardened ground Balls screw and linear motion bearing for better position accuracy and longer life. Ram tilting to maintain banding accuracy over period. Standard Accessories : Hydraulic Press Brake Main Drive Motor. Selection of ‘AUTO’ & ‘MANUAL’ mode through screen. Two axis controller with LCD monochrome screen & numeric keypad. 128 jobs X 16 bends program memory. Movable work station with pair of foot switch. AC Servo motor with resolver for back gauge drive. Hardened & Grounded Ball screw. Linear motion bearing on guide rods. Highly precise glass tube optical linear scale for accurate Y-axis position. Pair of lifting links. Pair of sheet support. One standard suitable five way die & Punch of EN-9* Centralized lubrication system with flow control valves for lubrication. Ram tilting arrangement on selected models. Optional Accessories : NC Press Brake AC servo drives for R-axis & Z-axis control of back gauging. Anti deflection unit (Manual / Motorized / Automatic) Sliding sheet support with Swing away stoppers. Hardened tools & special tools.** Hydraulic tool clamping. Photo electric fingers safety guard. Higher throat depth. Automatic lubrication system. Fast cycling models for high productivity. First fill of hydraulic oil.