water tank mould

65,000 Per Piece

Material : Stainless Steel

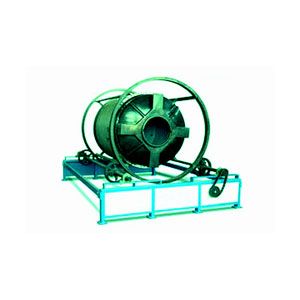

Single Station Bi Axial Machine

1,400,000 Per Piece

Voltage : 220 V

scrap grinders

Roto Mould Die

With enriched industrial experience and knowledge, we are manufacturing a wide assortment of Roto Mould Die.

...more

PVC Pulveriser Machine

Our reputation in the market is largely attributable to our precision-designed Twin Mill Pulverizer Machine. Features: Long service life High operational fluency Hassle free operations

...more

Pulverizer Machine

TECHNICAL SPECIFICATION Model DISC SIZE MAIN MOTOR POWER IN HP OUTPUT IN LLDPE (ROTO GRADE) IN KG/HR OUTPUT IN RPVC IN KG/HR. FLOOR SPACE IN MM IRP-PLV-50 300 15 H.P. 40- 50KG/ HR 50- 60KG/ HR 2300X1300X3000 IRP-PLV-70 300 20 H.P. 60- 70KG/ HR 70- 80KG/ HR 2300X1300X3000 IRP-PLV-90 400 25 H.P. 85- 95KG/ HR 95- 115KG/ HR 2400X1400X3100 IRP-PLV-120 400 30 H.P. 110- 125KG/ HR 120- 135KG/ HR 2500X1500X3300 IRP-PLV-150 400 40 H.P. 130- 140KG/ HR 140- 150KG/ HR 2700X1600X3600 IRP-PLV-200 450 50 H.P. 180- 200KG/ HR 190- 210KG/ HR 2900X1600X3800 IRP-PLV-250 500 60 H.P. 225- 250KG/ HR 235- 255KG/ HR 2900X1600X3800 IRP-PLV-TM-300 500 75 H.P. 275- 300KG/ HR 285- 310KG/ HR 4200X1600X3800 IRP-PLV-TM-400 600 100 H.P. 350- 360KG/ HR 360- 370KG/ HR 4500X1600X3800

...more

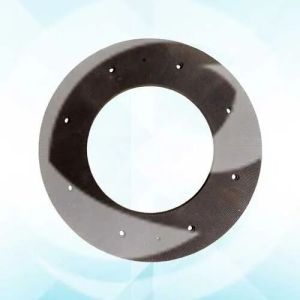

Pulverizer Disc

95,000 Per Piece

OPEN FLAME ROCK N ROLL ROTOMOLDING MACHINE

Owing to our state-of-art manufacturing unit and the usage of leading-edge techniques, we are able to present a comprehensive range of Flame Rock N Roll Machine.

...more

LLDPE Pulverizer Machine

We are dedicatedly engaged in manufacturing a commendable range of Single Mill Pulverizer Machine. Features: Minimum maintenance Long functional life High functionality

...more

FOUR ARM BI-AXIAL

Extruder Machine

bi axial rotomoulding machine

We have gained recognition as an eminent enterprise, devotedly engaged in manufacturing a broad range of Bi Axial Rotomoulding Machine.Description:We have come with newest making Bi-axial Rotomoulding Machine and Auxiliary Machineries for Plastic Industries. The company brings the world class information of Bi-axial Rotomoulding Machine and Rotomoulders in India.The Process: Rotational molding process is different as compared to other plastic processes.In the complete process, first the mold is loaded with raw material in resin from. The loaded mold is then shifted in to hot air oven where it is oriented and rotated at suitable low speed. As the molten resin gets properly heated oriented, it adheres to the mold's inner surface until completely fused. Then the mold is moved to the air, water or the both to slowly reduce the temperature when the mold is still in bi-axially rotating mode. Finally, the mold is dismantled to get the finished roto-molded product and is then again reloaded for next cyclic process.Salient Features:Most efficient in fuel and energy consumption compared to other types of machinesVery consistent product quality due to smooth bi-axial rotational, highest production due to lowest cycle timeUniform heating of the mould with forced air circulation in heating chamberUniform distribution of material of hence possible to produce tank with lesser weightBest compatibility in market due to lowest production cost per tank.Lowest rejection rate due to sound and proven technologyClean and silent operation of machineFlexibility to produce double and triple layer tanksAC variable drive for all minor and major axes for minute and accurate speed controlControl panel is equipped with ac drives, digital indicators, temperature controllers, timers and advance automation circuit for entire process control and all necessary safety features.

...moreBe first to Rate

Rate ThisOpening Hours