Mild Steel Rotary Dryer

Get Price Quote

1 piece (MOQ)

Mild Steel Rotary Dryer

Get Price Quote

Hmt-fytech Infrared Paint Dryer, sport welding machine, Plasma Cutter

Best Deals from Industrial Dryers

Tray Dryer

500,000 - 2,000,000 Per Pieces

1 Piece(s) (MOQ)

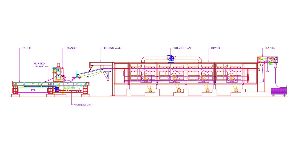

Horizontal Conveyor Dryer

1,000,000 - 2,500,000 Per Piece

1 Piece(s) (MOQ)

Tray Dryer

Get Price Quote

relax dryer machine

Get Price Quote

Key Features Air locks at the fabric entry and exit openings Special panelling tor low heat radiation Slot nozzle system Integrated exhaust air duct All heating options available including indirect gas heating system Modular chamber design with space saving construction and integrated exhaust duct Modular design Operator friendly with various permutation of fabric entry and delivery TwinAir principle of independent airflow regulation for top and bottom air

Agitated Thin Film Dryer

Get Price Quote

Due to its inherent design features, it is ideal for thermal treatment of solutions and heat sensitive products, where reduced operating temperatures and vacuum operating pressures are desirable. The typical Agitated Thin Film Evaporator consists of a tubular heat transfer area with an external heating jacket and a fast-revolving, inner rotor with flexible or rigid wiper elements. The driving speed is adapted to the product being handled, its particular specifications and task. The feed product is evenly distributed by the rotor and its wipers over the heating surface, forming a thin liquid film of uniform thickness. Highly turbulent swirls are produced at the tip of the rotor blades and wipers with intensive mixing and agitation of the product, as it comes into contact with the heating surface. This assures excellent heat transfer combined with constant renewal of the product film and provides an even heating and short residence time of the product through the heated zone. Key Advantages Good heat conductivity (k-value), even when working with highly viscous and contaminated products Minimal thermal stress, thanks to low operating capacity, therefore a short dwell time (10-20 seconds of mean dwell time) No dead zone, therefore overheating prevented and perpetual high product quality guaranteed Continuous mechanical cleaning of the heating surface prevents incrustations High evaporation rates, due to highly turbulent film and large difference in temperature Gentle evaporation, due to short residence times, rapid conveyance in the heated zone and the constant product film renewal, happens often Combined with suppressed boiling points due to operation under vacuum Reduced need for maintenance because of sophisticated bearings and shaft sealing parts Shorter downtime and assembly time for maintenance and inspection No corrosion as outside surface is usually made of stainless steel Evaporation in one pass, no circulation Small film thickness, no hydrostatic height High turndown ratio and high flexibility for variation in requirements Low operating pressure down to 1 micron to reduced boiling temperature Single step drying because of unique designed combination of vertical and horizontal dryers Effective evaporation of concentrated slurries, heat sensitive products, viscous and fouling fluids up to 99% in a single pass Simple installation as the equipment is supplied skid mounted with all inter connecting piping, condensers and vacuum system Single source responsibility for all project stages because of combined expertise in vacuum technology, heat transfer, evaporation, crystallization and drying – a design mix which gives optimal results Applications Mainly used for difficult vaporization and heat exchange processes, especially where products to be handled are highly viscous and conventional plants can no longer meet user demands because heat transfer is insufficient. Due to the liquid film, mechanically generated on the heating surfaces, thin film equipment achieve much better heat transfer rates, even with highly viscous products containing solids. To concentrate highly viscous products, polluted liquids, salt solutions, oils, resins, etc As a sump evaporator for vacuum rectification columns Sludge drainage To continuously dry powdery residues Distillation of high-boiling substances under high vacuum Degassing and/or removal of volatile components of highly viscous products Heating or cooling of viscous solutions Improve product quality by removing colour bodies, minimizing impurities and eliminating thermal degradation Increase product recovery by reclaiming additional bottoms product from overhead and distillate products from bottoms Separation of close-boiling compounds Enhance product recovery Recovers additional bottoms product from overhead

continuous fluid bed dryer

Get Price Quote

continuous fluid bed dryer, Vacuum Tray Dryer Machine, Double Cone Blender

Vacuum Drying Plant

Get Price Quote

Water in the active parts of the transformer can have adverse effect on its lifetime. The indicative lifetime of insulation at 80 C and 1% moisture is around 40 years whereas with 3% moisture it is 10 Years. Furthermore the reliability and overload capacity of the transformer are also affected when moisture is present. Transformers are more susceptible to mechanical stresses during short circuits when moisture is present. Vacuum Drying uses hot air circulation to remove moisture from the insulation Vacuum Drying is one of the most common processes which reduces the moisture content from the insulation. Using hot air circulation and vacuum, rapid drying can be achieved without damaging the product. SAVAS has installed a large number of vacuum drying plants as per customer requirements. Our experience enables us to understand your requirement and provide standardized components and solutions tending to your needs.

Rotary Air Dryer

100,000 Per Piece

Continuous MASTER BATCH DRYERS

Get Price Quote

We have the in house capabilities for Design and Development of Continuous Polyester Chips Dryers. These dryers are energy efficient and guarantee a trouble free operation. We have also suppilied Master Batch Chips drying systems to polyester spinning plants.

Industrial Dryers

Get Price Quote

Industrial Dryers, Cooling Tower, Loader, Dehumidifier, moulds plastic

Centrifugal Dryer

Get Price Quote

Centrifugal Dryer, ss water tank, blade grinder machine, Granulator Machine

Rice Mill Dryers

Get Price Quote

Rice Mill Dryers, Corn and Paddy Dryer 40 Ton, heat radiator

Tray Dryer

Get Price Quote

Tray Dryer, pharma machineries, Colloid Mill, Dust Extractor, de dusters