12kg Gold Melting Machine with Tilting Unit

Get Price Quote

1 Piece (MOQ)

High Temperature Burner

Get Price Quote

Best Deals from Industrial Furnace

Electric Furnace

100,000 Per Set

SILICONE CARBIDE BURNERS

Get Price Quote

The above problem can be avoided in case of Burner Tip lined with CN-178. SiC has smooth surface and it it design in such way that it remains free float in Steel body and therefore warpage can be avoided at high temperature due to difference in thermal expansion of steel and SiC. CN-178 retains its hardness at very high temperature as encountered in firing zone of boilers and thus it is the best material under such working condition. The Baffle plates made of SiC are excellent in Erosion wear at high temperature and they support in proper distribution of coal for optimum firing for long time. The higher life of the SiC reduces the frequency of shut down and thus production loss in shut down.

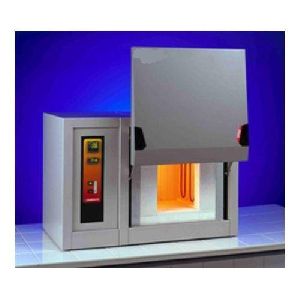

High Temperature Furnace

Get Price Quote

Micro Thermal Inc. is the profound organization involved in manufacturing and exporting of high temperature furnace in India.

Furnaces structure

Get Price Quote

We offer Furnaces structure. It is 15000 kgs Tilting Furnace Structure Job work done with all machining components.

BIO INDUSTRIAL BURNER FOR GAS

Get Price Quote

The BIO burner is designed for industrial furnaces and firing systems in the iron and steel industries in the precious, non-ferrous, and light metal sector, as well as in the plastics, fiber, and paper industries. Other fields of application are thermal incineration installations, as well as dryers and hot-air generators. For low temperature applications (e.g. for crucible heating, radiant tube heating, or hot-air generation), the burners are equipped with a heat-resistant steel attachment tube. For high temperature applications (e.g. forging furnace), the burners are used in combination with a burner quarl made from refractory concrete. Different flame shapes can be achieved by using burner quarls with a different geometry. The burner can be adapted to the system requirements using different burner tube lengths. Large capacity range up to 1000 kW Maintenance-friendly thanks to modular design Robust burner design Direct or lance ignition Control via ionization or UV sensor Suitable for new systems and modernization of existing systems thanks to individual length adjustment Air preheating to 450°C available as an option Low polluting level thanks to optimized combustion For installation as ceiling or side-wall burner thanks to arbitrary installation position Can be combined with different combustion chamber shapes

Hardening Tunnel

Get Price Quote

FEATURES Specially designed arrangement to hard candy&Ice Cream in very short time. Robust & Elegant aesthetically design. Low power consumption due to efficient refrigeration system & PUF Insulation. Efficient refrigerated system & chambers maintain a temperature even at working time. Automatically control of temperature Defrost System by specially designed programmable temperature Controller. High density PUF Insulation with outer & Inner covers in S.S. 304

Induction furnace coil

Get Price Quote

Induction furnace coil, Induction Furnace Crucible

induction melting furnaces

Get Price Quote

induction melting furnaces, electric arc furnaces

Bright Annealing Furnace

Get Price Quote

Bright Annealing Furnace, pilger die, instrumentation tubes

Solar Thermal Crematorium

Get Price Quote

Solar Thermal Crematorium

crematorium

Get Price Quote

crematorium

Bright Annealing Furnace

Get Price Quote

Bright Annealing Furnace, Pilger Mills, Small diameter tube

Electric Induction Furnace

Get Price Quote

Electric Induction Furnace, Centrifugal Casting Machines

Induction Furnace

Get Price Quote

Induction Furnace

induction furnace parts

Get Price Quote

induction furnace parts, Industrial Hardware, conveyers system