Muffle Furnace

Get Price Quote

As a promising name, we bring forth high quality product range that is designed and developed using the best in class raw material and modern work methodologies. Besides, we make sure that the basic material is sourced from the trusted places. Our company is well versed with online as well as traditional payment methods. As per requirements of patrons, we can sign an agreement for payment with suitable terms and conditions. Our innovative heating furnace works with a heating speed of 15oC/min.

Muffle Furnace (HSW121)

Get Price Quote

Our company is a trusted Manufacturer and Supplier of Muffle Furnace (HSW121) from Gujarat. The Muffle Furnace we make available is easy to install, simple to operate and has long functional life. Our Muffle Furnaces are sturdy in construction and highly durable. Muffle Furnace offered by us are widely demanded in petrochemical industry, research institutes, national laboratories, atomic energy, defense and public sector units.Specifications : Outside Body made of M.S. Sheet powder coated Inner muffle of Ceramic with high grade ceramic instillation door insulation of HFK brinks Heating element are made from kanthal A1 Wire A uniform distribution through all 4 sides with mental wire Max Equipped with digital temp Controller cum indicator fitted on top side of the unit with indicating lamps & switches A Special type of thermocouple fuse for safety to avoid over heating Power supply 230 Volts, 50 H2 Optional Accessories : Digital Timer Solid State Fuses for Extra Safety PID Controller with Printer interface

Best Deals from Industrial Furnace

heat treatment furnace

325,000 Per Piece

1 Piece (MOQ)

Graphite Electrodes

Get Price Quote

They are the pioneers of graphite electrode machining in the country. They continue to dominate the Graphite Electrode EDM Market 8 Years after being the first to launch this Product commercially. True to their name, Prime Industries based in Nasik has become synonymous to graphite machining and the company has carved a niche for itself in the market – It is the First choice for Best Quality Graphite Electrodes in the Indian market.

Vibratory Furnace Charger

Get Price Quote

Jaykrishna magnetics manufacturer vibrating furnace charges are effective solutions to problems such as higher labor cost, hazards to fund operators faced in foundries, melting shops etc. Such a kind of automation allows foundry men to work at a safe distance thus preventing injuries arising out of molten splash.

Gas Burner

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

LIGHT WEIGHT MUFFLE FURNACE

Get Price Quote

Introduction In this improved model, ceramic fiber wool insulation (instead of brick insulation) has been provided resulting in weight and size reduction of furnace. The weight and size of the furnace is 1/4 and 30% respectively as compared to brick furnace. The heat up time is less. heat loss is very low-resulting in power saving.

Vibrating Furnace Charger

Get Price Quote

1 Piece (MOQ)

Muffle Furnace

24,000 Per Piece

1 Piece (MOQ)

Industrial muffle furnaces are specially designed to suit IS & ASTM Standard. IT is applied in growing fields of Medical research, agricultural, industrial, metal treatment, ash determination & wool industries. Technical Specification: Outside Body made of M.S. Sheet powder coated Inner muffle of Ceramic with high grade ceramic instillation Door insulation of HFK brinks Heating element are made from kant hal A1 Wire A Uniform distribution through all 4 sides with mental wire Max. Working temp up to 1140 ˚C Micro Processor PID Digital temp. Controller cum indicator fitted on top side of the unit with indicating lamps & switches A special type of thermocouple fuse for safety to avoid over heating Power supply 230 Volts, 50 H2 Sizes available for industrial muffle furnaces are as below. Inner DimensionRating K. W. 9″X 4″X 4″ 1.7 10″ X 5″ X 5″ 2 12″X 6″X 6″ 3 12″X 8″X 8″ 3.5 18″X 9″9″ 5

Cupola Furnace

Get Price Quote

biomass pellet bhatti

61,000 - 95,000 Per 1

1 Piece (MOQ)

Continues pellet feeding stove with attachment

Laboratory Muffle Furnace

20,000 Per Piece

HIGH TEMPERATURE FURNACE – Outer Body Double Walled M.S. reinforced with iron angles duly Powder Coated Heating is done by Silicon carbide rods Max. Working Temp. up to 1450°C MAXIMUM FURNACE TEMP. UP-TO – 1150 WORKING TEMP. 1100° WORKING SIZE - WATTS. 9″ X 4″ X 4″ - 2000 10″ X 5″ X 5″ - 2500 12″ X 6″ X 6″ - 3500 12″ X 8″ X 8″ - 5000 18″ X 9″ X 9″ - 6000 WORKING SIZE 4” x 4” x 9” (100 x 100 x 225 mm) 5” x 5” x 10” (125 x 125 x 250 mm) 6” x 6” x 12” (150 x 150 x 300 mm) 8” x 8” x 12” (200 x 200 x 300 mm) 9” x 9” x 12” (225 x 225 x 300 mm) 9” x 9” x 18” (225 x 225 x 450 mm) OPTIONAL Microprocessor Based PID Controller OR Programmable Controller with ramp and soak facility Thyristor system (Single Phase) Thyristor system (Three Phase)

smelting furnaces

5,000 - 9,000 Per Piece

Muffle Furnace

Get Price Quote

Industrial Pellet Burner

Get Price Quote

We offer industrial pellet burner. Industrial pellet burner is lower cost of fuel compared to oil (hsdldofo) & gas (lpgpngcngpropane). It is storage silo provision for fuel storage & to avoid frequent re-filling of fuel during process.it is very small ash content as residue after burning i.e. @5%

Industrial Gas Burner

35,000 Per Piece

Ice Cream Hardening Tunnel

332,000 Per Piece

1 Piece (MOQ)

heat treatment furnace

325,000 Per Units

1 Units (MOQ)

Electric Melting Furnace

Get Price Quote

Induction Melting Furnace

Get Price Quote

Ecoflame Industrial Oil Burner

Get Price Quote

Aluminum Annealing Furnace

Get Price Quote

Aluminum Heat Treatment Furnace is used for Annealing, Normalizing, Hardening, Stress Relieving, Solution Annealing, Tempering, etc. of various grades of Aluminum in the form of forgings, castings, fabricated components etc. Inherent features of this product are : Robust MS shell to withstand continuous operation. Sturdy bogie design to take care of the charge weight Furnace can be offered with single bogie or double bogie, Heating elements operating on low surface load for longer elements life and continuous trouble free furnace operation. Refractory and insulation of high quality bricks / ceramic fiber for energy conservation. Heat loss prevention by Ceramic Fiber rope for door. Perfect temperature uniformity in the furnace useful space. Automatic temperature control by PID Temperature Controller. Electrical switch gear items of reputed make, along with controller housed in aesthetic control panel. Safety interlocks and protection devices for safe furnace operation. Areas of application : For Heat Treatment process of Aluminum like, Annealing Tempering Nitriding Aging Quenching Hardening Chamber Sizes : Custom built to suit customer’s specific requirements. Temperature Ranges : Up to 650°C Heating Medium : Electrical Control Panel Thyristor Based Power Control Panel. Temperature Based Power Control Panel.

Gas Burner

Get Price Quote

We are Offering Monoblock Type Gas Burner.

Ladle Pre Heater

Get Price Quote

1 Set(s) (MOQ)

We are offering ladle pre heater. Salient features : easy to operate fuel : lpg diesel kerosene efficient sturdy design

Hardening Tunnel

Get Price Quote

Taj Hardening Tunnel: We offer Hardener Tunnel: Specially designed arrangement to hard candy & ice-cream in very short time Robust & elegant aesthetically design. Efficient refrigeration system & chambers maintain a temperature even at working time. Automatically control of temperature defrosts system by especially programmable temperature controller. High density puff insulation with outer & inner cover in S. S Hardener Deep Freezer Static Type Hardener Forced Draft Type / Tunnel Type. Blast Freezer.

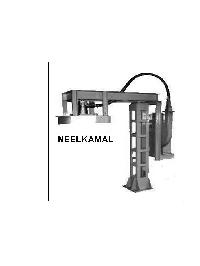

Vibratory Furnace Chargers

Get Price Quote

Vibrating Furnace Charges are effective solutions to problems such as high labour cost, hazards to furnace operators faced in foundries, melting shops etc. Such a kind of automation allows foundry men to work at a safe distance thus preventing injures arising out of molten metal splash. It also facilitates in rapid and quick charging of the furnace thereby allowing maximum utilization of the furnace. In addition to this, the damage to furnace lining is avoided which normally occurs in manual charging of the furnaces. The required amount of scrap metal is loaded into the storage hoper at the loading point. The trolley the carries the vibrating feeder along with the storage hopper to the furnace charging point. Here, the vibrating feeder is energized and the material is effectively discharged into the furnace as per the required capacity. As the metal is melted down, fresh batch of metal can be fed into the furnace thereby keeping the furnace full. The capacity of the vibrating feeder can be varied by varying the amplitude of variations. The amplitude of vibrations can be varied by adjusting the position of centrifugal weights or by using a variable frequency drive (optional). A control panel specially designed to suit individual client requirement depending on the sequence of operations required is provided.

Rotary Furnace

275,000 Per

Hardening Tunnel

Get Price Quote

» Specially designed arrangement to hard candy & ice-cream in very Short time. » Robust & Elegant aesthetically design. » Efficient refrigeration system & Chambers maintain a temperature even at working time. » Automatically control of temperature defrost system by specially programmable temperature controller. » High density PUF insulation with outer & inner covers in S.S.

Hardening Annealing Furnace

Get Price Quote

We offer Hardening Annealing Furnace.

High Temperature Burner

Get Price Quote

We are offering high temperature burner etc. We specialize in offering quality high temperature burners for heating and melting treatment which meet the variegated needs of our clientele for gas fired driers. We also provide customization facility and offer them at cost effective prices. These are appreciated for their high performance, easy installation, less maintenance, effectiveness and unmatched quality. burner body:-graded ci casting capacity:- 5,00,000 kcal to 12,50,000 kcal/hr fuel:natural gas and lpg ø wide range of application, up to 1500° c operating temperature. ø 10,000 to 8,00,000 kcal/hr range available ø durable construction ø wide air / fuel ratio adjustment ø low maintanance and high efficiency ø smooth operation ø fully automatic control systems for saving more fuel ø high efficiency ø reduce electrid consumption applications:- ø ceramic tunnel and kilns ø heat treatment furnaces ø preheaters galvanizing tanks ø air heating and drying ø forging furnaces ø alminium melting furnaces ø glass melting furnaces ø non ferrous melting furnaces ø rotary furnace / rotary calciners ø boilers, air heaters, incinerators