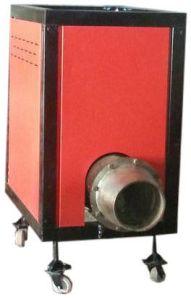

Pressure Jet Burner

85,000 - 180,000 Per Piece

1 Piece (MOQ)

Induction Furnace

600,000 - 5,000,000 Per Piece

1 Pair (MOQ)

Best Deals from Industrial Furnace

Gold/Silver Induction Furnace

130,000 - 250,000 Per Set

1 Piece (MOQ)

Clinker Grate Cooler

Get Price Quote

Highly praised for presenting high-grade quality Clinker Grate Cooler, we are a celebrated Supplier in the market. We are capable of delivering the bulk consignments of the clientele effortlessly as we have excellent storage facilities. We have segregated units in the warehouse that helps us in delivering all the products systematically. Features: Precision made High strength Industrial application

Heavy Oil Burner

18,500 - 80,000 Per Piece

Electric Furnace

Get Price Quote

Our motto is to deliver qualitative products to the end user and for this, we check each product at all stages. With us, one can stay assured about the security of their payments as we follow safe and secure online and offline payment modes. We facilitate our patrons with the methods like bank deposits, cash, electronic funds transfer and various others.

Muffle Furnace

25,000 - 250,000 Per Piece

MODE OF HEATING :Rasayan muffle furnace is double walled convection heated unit. Outer body of the unit are made of heavy gauge CRC sheet duly pretreated with primers rust free well finished powder coated. The inner chamber made of special design ceramic material. The gap between both chambers filled with high density sera wool for super fast heating & reduces heat loss & power consumption.Other Details : Heating : Indirect heating system provided in our units compressing of air heater made of heavy gauge A-1 grade nicrom wire of suitable wattage (silicon carbide rod heating also available at optional.) Front Panel : Front panel of our unit comprise of ON/OFF switch, temperature controller, main cord, heater indication lamp etc. Features : Microprocessor based four digit seven segment Dual digital display type PID controller for accurate temperature controlling. Dual display upper display shows actual temperature & lower display shows set point High density sera wool insulation permits faster heat up, reducing heat loss & energy consumption Embedded heating element on top, bottom and both sides improves temperature uniformity Side opening door doubles as a shelf for loading and unloading Door safety switch stops power to heating elements when door is opened. (Optional) Thermocouple break protection cuts power to heating elements, preventing a •thermocouple failure runaway condition 0.95 cm (0.38 in) diameter port in chamber rear for monitoring temperatures with independent measuring devices Includes: Thermocouple, line cord and plug Alarm : Audio visual alarm facility when process complete at optionalTemperature Control / Range : Temperature Range: +5°C to 1000°C or 1100°C or 1200°CTemperature Sensitivity: +/- 2° c or betterOptional : PPI PID based programmable controller with original sensor Temperature Accuracy: < 0.5 °C: -Rate:

Cold Rolled Galvanizing Plant

Get Price Quote

We are a dynamically developing company that has evolved itself as a prime manufacturer and exporter of superior range of multifarious products such as galvanizing plant, pickling plants, pickling tanks and anti-corrosive equipment made from various industrial thermoplastics.

hot dip galvanising plant

Get Price Quote

Plast World introduce ourselves as a Leading manufacturer, Supplier and exporter of a comprehensive range pickling tanks such as pickling plants for galvanizing tower , pickling plants for transmission tower, pickling plants for S.S. M.S. Pipes ,Tubes , Wire coils, Stripe etc.We design pickling Tanks that are used by galvanizing plants manufacturers for usage in high tension transmission Tower , poles, Pipe Cable Trays ,Grating , Guard, Tails, Railing and other steel items.

Pressure Jet Oil Burner

160,000 Per Piece

1 Piece (MOQ)

Muffle Furnace

Get Price Quote

The Muffle Furnace, provided by us, is acclaimed for its sturdy and high durability. Our company has a convenient and noncomplex payment procedure. Patrons can make payments through a method with they are comfortable. We are open to receiving payment online or offline. In order to keep our offerings in safe and secure conditions, we have developed a storage unit and keep it updated with the defined industry standards.

induction furnace spare parts

Get Price Quote

Our company is highly acclaimed in offering a wide range of Induction Furnace Spares Parts. We undertake repairing or servicing of following types of induction furnaces & also supplying spares for the same. The wide range of products offered by us include Transite furnaces, Duraline furnaces, Steel shell furnaces.

Induction Furnace

Get Price Quote

Our Induction Furnaces are Designed and Produced By Studying all Available Existing Furnaces in the World, Adapting all Superior Features, Adding all Up to Date Technologies and Combining the Necessary Needs Indicated By Foundrymen. for the Coming Millennium Years of 2000 and Beyond Magnalenz Proudly Presents to Modern, Automated Foundries and Steel Plants the Most Economical, the Most Reliable, the Most Efficient and High Quality Induction Furnace Viz. Fermelt.fermelt Synergy - Some of Its Parts Are:thyristor Controlled Rectifier At Low Input Voltage the Furnaces Can Deliver Power Efficientlypower Adjustments Can Be Done Over a Very Large Range (5%?100%)line Voltage Fluctuations Cause No Damagepower is Curbed During Any Failure or Short Circuit Crippling the System, Thus Preventing Major Technical Problems and Expensessafety Margins in Power Semi-conductorsfermelt Works On Parallel Circuit Design. Even At the Highest Power Level the Thyristors Chosen Work Approximately At One Third of the Current. in other Words the Safety Margins On the Thyristor are Very High. Consequently, Low Heat Losses and Lower Operating Temperatures Extend the Service Life of Thyristors.reduced Melting Cost with Constant Power We Design and Program Fermelt Furnaces to Deliver Maximum Power from the Beginning to Reduce Melting Time and Achieve Lower Energy Consumption.higher Electrical Efficiencyfermelt Furnaces are Designed to Minimise Electrical Losses. Electrical Efficiency is 97% (over All)high Power Factorthe Reactive Energy Used On Fermelt Furnaces is Very Low and the Average Power Factor is Better Than 0.95, Thus Eliminating the Need for Additional Precautions to Improve Power Factor.safety and Protection Systemthe Advanced Parallel Inverter Circuit Design is a Result of Years of Experience that Has Enabled Us to Present One of the Safest Induction Furnaces.protection Featuresover-voltage Protection At Mains.over-current Protection for Thyristor & Capacitor.phase Protection At Input.over-voltage Protection for Thyristors & Capacitors.on all Main Water Cooling Branches, Temperature and Water-flow are Controlledearth Leakage Detector.air Temperature Sensor in Side Panel for Protection.mf Description of the Installationsmedium Frequency Furnaces Operate At Frequencies Ranging Form 150 to 10,000 Hz. such Furnaces Provide the Concentration of High Power in Small Volumes with a Definitely Higher Melt Rate.every Installation Consists Of1. Melting Crucible2. Solid State Power Converter3. Power Factor Compensation Capacitor Bank4. Ancillary Equipmentsmelting Cruciblestructurally It Consists of Three Independent But Interdependent Sections:1. Base Frame 2. Tilting Frame 3. Interchangable Inductor Comprising a Coil Made from Specially Shaped Copper Section Featuring Higher Strength and Higher Conductivity. the Melting Basin Positioned Inside the Inductor is Separated with a Thick Refractory Lining in Between. a Special Hydraulic System Ensures Easy Emptying, Smooth and Complete Pouring.mf Solid State Power Converterconverts the Line/mains Frequency Into Medium Frequency Required for Efficient Operation.the Features Include?1. Conversion from Ac to Dc2. Rectifying & Filtering Dc Current3. Converting Dc to Mf Ac4. Electrical Safety, Protection, Regulation and Control Circuits5. Closed Water Circuit with Water-to-water Heat Exchange and De-ioning with Demineralised Watermf Power Factor Compensation Capacitor Bankit Comprises a Set of Water-cooled Medium Frequency Capacitors Connected By Electrolytic Grade Copper Busbars to Avoid Losses Due to High Currents. It is Fitted Inside the Panel or Outside. Specially Protected Frames Automatically Compensate the Low Power Factor to the Furnace.ancillary Equipmentsadditional Equipment is Supplied to the Customer?s Specific Requirements for Better Functionality of the Medium Frequency Furnace Installations:1. Cooling Tower2. Step-up and Step-down Transformers3. Closed Loop Dm Water Circulation for Crucible4. Automatic Charging Equipments5. Energy Metering Devices6. Control and Programming of Power Absorbed During Production Cycle7. Eot Cranes8. Water Softening Plant24/7 Serviceround the Clock Service Throughout the Week is An After-sales Feature that Earned for Us the Reputation of Reliability.the Magnalenz Edge the Following Characteristics of Our Fermelt Furnace and the Smart Technology Give Magnalenz the Distinctive Competitive Edge?hi-tech Design Means Lower Failurethe Fermelt Solution Incorporates a Special System to Locate Faultsmagnalenz Has a Team of Trained and Experienced Engineerssuitable Design for Fast Servicetelephonic Advice for Fast Technical Aidbuilt with Care and Quality Workmanship for Fail-safe Performancein-house, State-of-the-art, World-class Testing Regimenclean Layout with Ample Space and Easy Accessibility to all Components Means Fast and Quality Maintenance and Servicingample Stock and Availability of Spare Parts

Diesel Filter

38,000 Per Piece

Muffle Furnace

Get Price Quote

Double walled with double insulation for minimum heat leakage & faster temperature rise. The outer casing made of thick CRC powder coated Heating chambers consist of rectangular horizontal totally enclosed muffle bracket Heating elements are made of Nichrome/Kanthal wise wounded externally on the muffle Temperature controlled by Micro Processors based Digital temperature Indicator cum Controller with CS/AI sensor. Maximum temperature 1000 Deg.C. working temp. 900 Deg.C. Various models with different temperature ranges are available.

induction furnaces

Get Price Quote

Pit Type Weighbridge

Get Price Quote

ADORN Pit type Weighbridges are designed for heavy usage and harsh environment. The sturdy and strong steel platform provides safeguard against lateral and sway movements. The weighbridge structure is accurately fabricated and built to high quality engineering standards for durable and accurate performance. In Pit type Weighbridge the weighing platform / deck is flushed with ground level. Platform structure and load cells are not visible and present under platform in pit. The manhole entry is provided for maintenance purpose. Pit mounted weighbridges are flush with the ground. As a result they pose no restrictions to vehicles and are therefore particularly useful at sites where vehicle flow can be in multiple directions. Pit mounted steel weighbridges are ideal for applications with heavy traffic and limited space.

Pit Type Gas Carburising Furnace

Get Price Quote

carburising is A heat Treatment process In Which iron or steel absorbs carbon liberated When The Metal Is Heated In The Presence Of A Carbon Bearing Material, Such As charcoal or carbon Monoxide, With The Intent Of Making The Metal Harder. Depending On The Amount Of Time And Temperature, The Affected Area Can Vary In Carbon Content. Longer Carburizing Times And Higher Temperatures Typically Increase The Depth Of Carbon Diffusion. When The Iron Or Steel Is Cooled Rapidly Byquenching, The Higher Carbon Content On The Outer Surface Becomes Hard Via The Transformation From austenite to martensite, While The Core Remains Soft And Tough As A ferriticand/or pearlite microstructure. This Manufacturing Process Can Be Characterized By The Following Key Points: It Is Applied To Low-carbon Workpieces; Workpieces Are In Contact With A High-carbon Gas, Liquid Or Solid; It Produces A Hard Workpiece Surface; Workpiece Cores Largely Retain Their toughness and ductility; And It Produces case Hardness depths Of Up To 0.25 Inches (6.4 mm). In Some Cases It Serves As A Remedy For Undesired decarburization that Happened Earlier In A Manufacturing Process.

Furnace Oil Burner

10,000 Per Piece

Mesh Belt Furnace

800,000 Per Piece

Muffle Furnace

Get Price Quote

system status- Digital Temperature controller- Micro processor based double display PID controller Heating- Through high grade nichrome wire Air circulation- ----------- Temperature range- Ambient to 950°C Temperature least count- 0.1°C Accuracy- ± 0.5°C Timer- Micro processor based double display digital timer (Optional) Timer range- 999.9 Seconds, Minutes or Hours Safety MCB- Available on electrical panel

Hot Dip Galvanizing Plant

3,200,000 Per Units

1 Units (MOQ)

pellet burner

110,000 Per Piece

Gas Burner

Get Price Quote

Gas Burner of Gas Burner, which is offered by us in various dimensions and specifications. This product is widely used in textile industry for direct firing purposes. It can also be used in different kinds of industrial & commercial ovens, furnaces, steam boilers, hot air generators, thermic fluid heaters, incinerators and so on.

Muffle Furnace

Get Price Quote

Double Walled with double insulation for minimum heat leakage & faster temp. Rise. The outer casing made of thick CRC Powder coated. Heating chambers consist of rectangular horizontal totally enclosed muffle bracket. Heating elements are made of Nichrome Kanthal wise wounded externally on the muffle.

cremation furnaces

2,800,000 - 7,800,000 Per Unit

We are the reliable manufacturers and exporters in the industry offer cremation furnace to our clients by employing high quality tools and techniques. Our products are highly environmental friendly and completely safe in use. Our products assure maximum outputs and 100 percent safe operations when used correctly. Some of the highlighting benefits of our product include ?

smelting furnaces

5,000 - 9,000 Per Piece

High Temperature Burner

Get Price Quote

We are offering high temperature burner etc. We specialize in offering quality high temperature burners for heating and melting treatment which meet the variegated needs of our clientele for gas fired driers. We also provide customization facility and offer them at cost effective prices. These are appreciated for their high performance, easy installation, less maintenance, effectiveness and unmatched quality. burner body:-graded ci casting capacity:- 5,00,000 kcal to 12,50,000 kcal/hr fuel:natural gas and lpg ø wide range of application, up to 1500° c operating temperature. ø 10,000 to 8,00,000 kcal/hr range available ø durable construction ø wide air / fuel ratio adjustment ø low maintanance and high efficiency ø smooth operation ø fully automatic control systems for saving more fuel ø high efficiency ø reduce electrid consumption applications:- ø ceramic tunnel and kilns ø heat treatment furnaces ø preheaters galvanizing tanks ø air heating and drying ø forging furnaces ø alminium melting furnaces ø glass melting furnaces ø non ferrous melting furnaces ø rotary furnace / rotary calciners ø boilers, air heaters, incinerators

Aluminum Annealing Furnace

Get Price Quote

Aluminum Heat Treatment Furnace is used for Annealing, Normalizing, Hardening, Stress Relieving, Solution Annealing, Tempering, etc. of various grades of Aluminum in the form of forgings, castings, fabricated components etc. Inherent features of this product are : Robust MS shell to withstand continuous operation. Sturdy bogie design to take care of the charge weight Furnace can be offered with single bogie or double bogie, Heating elements operating on low surface load for longer elements life and continuous trouble free furnace operation. Refractory and insulation of high quality bricks / ceramic fiber for energy conservation. Heat loss prevention by Ceramic Fiber rope for door. Perfect temperature uniformity in the furnace useful space. Automatic temperature control by PID Temperature Controller. Electrical switch gear items of reputed make, along with controller housed in aesthetic control panel. Safety interlocks and protection devices for safe furnace operation. Areas of application : For Heat Treatment process of Aluminum like, Annealing Tempering Nitriding Aging Quenching Hardening Chamber Sizes : Custom built to suit customer’s specific requirements. Temperature Ranges : Up to 650°C Heating Medium : Electrical Control Panel Thyristor Based Power Control Panel. Temperature Based Power Control Panel.

hot dip galvanizing equipment

Get Price Quote

The Keya Plast can supply as per your requirement with Pickling Plants Heating System, Protection bar against damage, Fume Exhaust & Scrubbing System, Hood, Ducting, Chimney & Canopy, Pipe separator system in tank, Load hanging system on tank, Tank covers lid, Integral Fume Ducting, Acid Circulation System, Installation Stat-up Training, etc. The Pickling Tanks are used for Galvanising Pipes & Tubes, Wires & Rods, Bars & Profiles, Sheet, Strip & Coils, Transmission Tower Structure, RCC TMT Rebars, Highway Guide Rails, Electric Poles, Electrical Overhead Hardware, Grating, Cable Trays, Wire Ropes, etc.