Triple Roller Mill Machine

Get Price Quote

Triple Roller Mill – STRM is used in the preparation of ointments, salves, dough and similar products. The hourly production is from 2 Kgs. To 12 kgs. depending upon the constituency of the material. Three hard stainless still roller, which are 110 mm long, and 50 mm diameter produce the Rolling action. Two outer rollers are spring supported to eliminate the possibility of damage to the rollers or to the operating mechanism. The space between the rollers is adjustable by turning one thumbscrew. This Attachment is Suitable to Attached in our Both Main Drive.

rotary printing machines

Get Price Quote

Key Features Original Zimmer Magnet System Plus for the color application Automatic pre-repeat adjustment and design memory One or both sided screen drive

Best Deals from Industrial Machine

Battery Plate Lug Brushing Machine

25,000 Per Piece

Pressure Relief Valve

750 Per Piece

1 Piece(s) (MOQ)

shrink PVC Label Cutting Machine

1 Per piece

01 piece (MOQ)

Horizontal Glass Beveling Machine

800,000 - 1,050,000 Per

10kg Rotary Oil Mill Machine

172,000 - 190,000 Per piece

1 piece (MOQ)

Automatic Six Head Ropp ROPP Cap Sealing Machine

Get Price Quote

DESCRIPTION "GMP" Automatic ROPP Cap Sealing Machine is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine. SALIENT FEATURES No container no cap arrangement. S.S. elegantly matt finished body. Single motor synchronizes conveyor, star wheel, & platform turret. Adjustable height of conveyor belt, to align with other machine of the line. Sealing pressure can be varied to suit different gauges and size of caps. Specially designed hopper is provided to increase storage capacity of bowl. Low noise level, low power consumptions. Self-lubricating UHMW- PE guide profile for low friction wears surface, smooth and noiseless conveying. Drain tray around the machine platform. SS cladding or hard chrome platting of all exposed parts to ensure long life and resistance against corrosion. Synchronized A/C drives to synchronize, Conveyor, Star wheel and Platform turret & capping bowl. Universal coupling for quick and easy setting of In-feed worm. Adjustable bottle height gauge for easy and quick setting.

Welding Electrode Making Machine

2,500,000 Per Set

Cup Filling Machine

Get Price Quote

1 Piece (MOQ)

Automatic Rotary Bottle Washing Machine

Get Price Quote

We are specialized in the processing and manufacturing of automatic rotary bottle washing machine. These machines are used to wash the containers of plastic, glass and so on and so forth. Moreover, these machines require low maintenance because of their durability. These machines are designed in such a way that they provide maximum benefit to our customers. Consequently, we have been reckoned as one of the most preeminent automatic rotary bottle washing machine manufacturers in India. Product Code : 06 Product Specification

Quality Shrink Wrapping Machine iso.

350,000 Per Piece

1 Piece(s) (MOQ)

Parameters: 1 1) plc: select 2) sensor: panasonic sensor 3) intermediate relay: schneider 4) temperature controller: select 5) contactor: schneider 6) pneumatic parts: janatics 7) timer: select 8) main switch: schneider 9) cylinder: janatics 2) technical parameters model radhe 900 (m.s) radhe 901 (s.s) power supply 3 phase and neutral 5060 hz 3 phase and neutral 5060 hz power 14 kw 14 kw packin gsize l 5500 x w 3000 x h 2000mm l 5500 x w 3000 x h 2000mm packing speed 0-6 pcsmin 0-6 pcsmin compressed air 5 kg 5 kg max current 63 amp 63 amp net weight 400 kg 400 kg radhe projects pvt. Ltd. Reg.office : 509,5th floor, iscon elegance, bh prahland nagar garden, s.g.highway, ahmedabad-380015 phone:+91-79-40075003 fax+91-79-40075003 email : radheprojects@gmail.com remark: 1. Terms of delivery: any indian seaport. 2. Terms of payment: tt,50%inadvance,50%before delivery. 3. Packaging: seller’s export standard, worthy of sea shipping. 4. Lead time :40 days after receiving down payment. 5. Guarantee period: within 12 months from delivery time.

Automatic measuring cup placement machine

320,000 - 350,000 Per 200 kg approx

Single Station Bi Axial Machine

1,800,000 - 2,800,000 Per piece

1 piece (MOQ)

Shrink Sealer Wrapping Machine

Get Price Quote

4 Arm BI Axial Machine

Get Price Quote

1 Piece(s) (MOQ)

Features : Faster production due to 3/ 4 arms design. Advantages of producing all tanks sizes/mix simultaneously. Microprocessor based PLC controlled ( Optional ) operation. Unique and precisely designed Oven chamber for efficient transfer in to molds and reduce cycle time. Unique special seal between doors and oven body to prevent heat losses. Facility to produce 3 / 4 layer and foam tanks. Facility and controls provided for Molds positioning. Over all smooth operation, silent, easy and faster production at reduced wastage. Facility for interchangeability of arms Advance and most preferred concept for best quality tanks production at lowest operating cost hence faster payback. Advantage of production of all types of rotomolding items in same machine. Machine control and operation with all safety features, interlocking, audio and visual alarm systems provided.

Single Sided Rotary Tableting Machine

Get Price Quote

Description:It is a square GMP model/single sided Rotary Tablet Press/ promising unmatched quality for small batch Production. Safety/enhanced performance/clean ability and ease of operation is its most significant features. The suitable model can be selected based on the tooling and output requirement from the 16, 20 & 12 station with “D”, “D” & “SPECIAL” tooling respectively. The 12 station model is available with “SPECIAL” tooling and tunnel type cam track having maximum tablet diameter of 40mm & maximum depth of fill of 30mm. SALIENT FEATURES : cGMP • In compliance with cGMP guidelines • Turret of SG IRON 500/7 Graded Casting • Robust with high quality Engineering • Small batch production • Safe/ Simple to operate and easy to maintain • Higher Turret RPM upto 42 • Main Moter AC Variable Frequency Drive (optional) • Force Feeder (optional) • Aluminum covers for Turret teeth

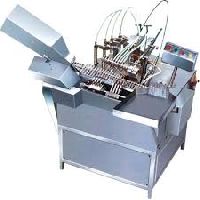

Ampoule Filling Machine

Get Price Quote

The sterilized ampoule tray can be directly loaded in to slant hopper of the unit. The synchronized star wheel Delivers ampoules, one by one on moving eccentric ampoule rack in single or two's or four's. During the stoppage of rack sequentially pre-gassing Filling, post gassing, pre heating (for single and double head only) and final Sealingannealing is achieved. At the end to the rack, optional synchronized pusher Pushes out ampoules in to tray in vertical position.

AUTOMATIC DRY POWDER FILLING MACHINE(Augur Type)

Get Price Quote

We are offering automatic dry powder filling machine(augur type).

Light Duty Lathe Machine

Get Price Quote

We are offering light duty lathe machine. vahanvati machine tool provides different types of lathe machines including light duty lathe machine. These machines are used for accurately machining comparatively hard materials. Our light duty lathe machine incorporate the latest technology to ensure improved performance. Lathe machines are used in power plants, steel rolling mills, tool rooms, ship building, repairing shops, paper mills, workshops, textile, oil, mining industries etc.