Ribbon Blender Mixer machine

250,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

75,000 - 500,000 Per piece

1 piece (MOQ)

Best Deals from Industrial Mixers

ribbon blender machine

25,000 Per Piece

1 Piece(s) (MOQ)

Food Process Mixing Tank

128,000 Per Number

Mass Mixer

150,000 - 450,000 Per piece

1 Piece (MOQ)

Powder Mixing Machine

95,000 - 690,000 Per Piece

We are menufecturing different types ribbon blender or mixture machine as per requirement. please contact feel free to us on 9825641435.

Food Process Mixing Tank

85,000 Per Piece

1 Piece (MOQ)

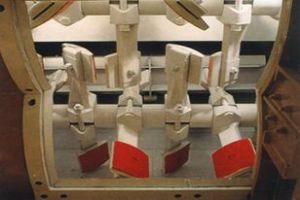

gravimetric blender

Get Price Quote

Easy access to all material contact points for fast and safe cleaning during color or resin changes. Material compartment access doors, removable weight bin, mix agitator and mix chamber liner allow quick efficient cleaning. Features Spot-on accuracy - Blend accuracy to 'A of 1% Repeatable, consistent performance job to job Simple to use touch screen control Quick recall recipes gives repeatability you need Improved accuracy on lower dosing percentages Fast accurate response times Enhanced algorithms provide better weight reading accuracy Diagnostic screen display target set-point percentage and actual percentage dispensed Precision ratio control - all components Instantly see your materials usage Set and save 1000 different recipes

Mixer Machine

Get Price Quote

Salient Features of Mixer Machine :: Turbo Mixer Is suitable for Mixing Polymers and other Ingredients. The Machine consists Stainless Steel Vessel, Mixing Tool And Mechanical Discharge Control Cabinet and Other Accessories. Mixing Vessel : 5mm Thick Stainless Steel Vessel having Outer Jacket fabricated having housing various openings for material feed. Complete Vessel Is mounted on Heavy Cast Iron Bearing Housing on Sturdy Frame of fabricated Steel Structure. Bearing House : Bearing House Is fitted directly on the Frame below the Vessel Housing main device shaft with two nos. of Ball Bearings. Resin leakage to Bearings Is prevented by Mechanical Rotary Shaft Seal and Gaskets. Mixing Tool : Four / Six Blades of Stainless Steel dynamically balanced to Avoid Vibration and are Mounted on Main Shaft driven by a Motor. Drive : A.C. Motor with Single Speed Drives and the Main Shaft. Electrical Equipments : All Controls are mounted In a Combined Switching Control. It Includes Ammeter, Voltmeter, Temperature Indicator with Thermocouple, Starter to drive Motor and other Electrical Equipments.

TWIN-SHAFT PUGMILL MIXER

Get Price Quote

1.Direct gear-motor drive with transmission through synchronous, helical spur gear. 2.Robust and rugged design to suit hardest site condition. 3.Inner mixer wall is bolted with extremely high wear resistance austenitic Ni-Hard liners. 4.Mixer arms and paddles, which are made from high-chrome alloy-steel and special caststeel ,are bolted to allow for easy replacement of these wear parts. 5.Mixer discharge gate with wear resistance liners is a rotary type and pneumaticallyoperated by two cylinders. 6.Capable to produce homogenous mix within a short mixing time, minimizing oxidation of bitumen. 7.Non-contact infrared temperature measurement at mixer outlet.

Propeller agitator

100,000 Per unit

100 unit (MOQ)

Double Cone Blender

Get Price Quote

OPERATIONThe Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts made out of stainless steel of required grade by customer. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. SALIENT FEATURESThe conical shape at both ends enables uniform mixing and easy discharge. All contact parts are made out of stainless 304 or 316 quality material, as required by customer. Maximum care has been taken to ensure safe operation of the unit. Manual rotating facility with hand wheel for inching. The same will be provided with ss cover & limit switch. ( In 200 Kgs. & above model ) Two nos. of safety road will be provided at back side. ( One LH side & one RH side ) Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning. with 04 nos. of fixed buffels with mirror polished provided inside the cone. be mirror polished from the inside & outside & structure will be matt polished. All moving parts covered with SS304 covers. Safety guards made from SS304 pipes provided in front of the m/c with limit switch. Panel fabricated from SS304 material with facility of three phase indication, D.O.L. tarter, digital timer & Amp. Meter. As per customer requirement machine will be provided with left side drive or with right side drive. The conical shape at both ends enables uniform mixing and easy discharge. All contact parts are made out of SS304/316(as per customer requirement) quality material. Maximum care has been taken to ensure safe operation of the unit. Worm reduction gear use for speed reduction. Food grade rubber gasket will be used on both end of cone as well as in butterfly valve. Inside & outside of the cone will be polished to the mirror finished. General structure made out of SS304 and Polished to the matt / mirror finish ( as required by you ) in GMP Model. All safety guards & covers made out of SS304 in GMP Model. Hand wheel will be provided for manual tilting of cone. Safety guards provided with limit switch to not start the machine when safety guards are not in proper position.

Eductor

Get Price Quote

The basic requirement for Eductors are to perform according to given parameter with trouble free operations. These are used at mainly at remote locations or at very challenging locations or experiencing extreme weather conditions. AXIS brings you the equipment to meet diverse and exacting demand which runs trouble free for 24 X 7 in Power generation sector, Chemical plants, Process Plants, Instruments Panels, Food Processing machinery. AXIS Eductors offer a non electrical means, no mechanical moving parts for transporting a sample stream. Eductor work on the basic flow dynamics principles. The principle of venturi nozzle applies here. This involves taking a power of one stream and accelerating through tapered nozzle by increasing velocity of the stream and create a vacuum due to increased flow & decreased pressure. This will move power of one stream to create a vacume for other. In turn both are mixed together & discharge from the exhaust port. Eductors are also known as Mechanical Vacuum Pump or Venturi Pump. Application like hazardous area where electrical apparatus are the challenge to use, can have Eductor as best alternatives.

U Type Mixer

Get Price Quote

High Speed Mixer

500,000 Per Piece

Jet Sharing

Get Price Quote

Jet Mud mixer is special equipment to prepare and increase the drilling fluids weight by adding and mixing bentonite, change the fluid density, change the mud density, viscosity, and dehydration. The effect is more prominent matching with Shear Pump. GNSL jet mud mixer is a unit used together with the solids control system for petroleum drilling and horizontal directional drilling(HDD). The unit includes one sand pump, one jet mixing hopper and one jet mixer that are installed in a base with pipe valves. It is safe and stable and can be moved conveniently. At the same time,we can make Twin-Jet Mud Mixer according to the user requirements.It is designed by bhagyoday bentonite mud mixer,drilling mud tank jet mixer.

Contra Mixer

Get Price Quote

the contra rotary mixer is designed to achieve better mixing and consistent granules at lower operating cost along with higher productivity. It works with full vacuum or pressure and at higher speeds. It is comprehensively jacketed for steam or hot water circulation. It comprises of paddled form blades for movement of material back towards the center of the container. The contra mixer comprises of mainly two blades including that rotate clockwise and anticlockwise simultaneously. There are two different shafts that include, solid and hollow shafts. The vessels are fabricated in a form that it can handle complete vacuum or pressure. characteristic features the contra mixer is equipped with pitched paddle blades throughout the height of vessel intimate mixing, shearing and blending possible with the central shaft in the rotary mixer effective teflon scrapper blades for scrapping product material from the vessel wall uniform and homogeneous mixing of viscous products due to the contra rotary motion efficient sanitary design to prevent product contamination all the contact parts made up of ss 314 and ss 306 material compact in size with smaller floor size all the non contact parts configured with mild steel or ss 304 material mounting possible with the mounting of product containers on the mounted legs steam circulation function available for mixing bowl equipped with digital temperature indicator for keeping a check on temperature parameters thick glass wool insulation available no air contamination due to vacuum operation ideal mixer for high density and viscosity materials provides durability, sturdy design and smooth functionality flame proof control panel available for safe functioning appropriate for thorough mixing, blending of toothpaste, grease and all other viscous compounds also solid shaft with multiple paddle blades for rapid operation inbuilt homogenizer with mechanical seal, that is helpful for emulsification

REVERSIBLE CONCRETE MIXING MACHINE

Get Price Quote

Chassis : Heavy Steel Sections have been used for durability & Four Pneumatic wheel are providedOut Capicity : 15m/hr.

tank mixer

Get Price Quote

TANK MIXER – EDUCTOR TYPE As an eminent enterprise, we are manufacturing, exporting and supplying highly efficient and a wide array of Tank Mixer. These industrial mixers are obtainable in diverse specifications. Moreover, these industrial mixers are strictly inspected on a variety of stern parameters towarranty their high performance, before their closing dispatch. Offered industrial mixers are widely cherished by our clients for their exceptional features. FEATURES: Hassle free performance Precisely design Low maintenance

Stainless Steel Liquid Mixing Tank

Get Price Quote

20 Kg Flour Mixing Machine

31,525 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

Oil Mixing Tank

80,000 - 100,000 Per Piece

1 Piece (MOQ)

High Speed Paint Mixer

Get Price Quote

1 Piece (MOQ)

We at Shree Engineering Services as a High-Speed Paint Mixer Supplier are primarily occupied with offering a diverse variety of Paint Mixer Machine that is manufactured utilising premium grade raw materials and cutting-edge technology. Our machine is put through rigorous testing to assure its effectiveness and flawlessness. Our equipment can mix paints more effectively, providing you with proper colouration for future usage. They require minimum maintenance and are tested under various aspects to assure their performance, flawlessness, and running costs. Our machine is simple to install and run, and it is very effective, affordable, and safe to use. Our machine is offered at industry-leading prices and in accordance with the needs of our customers in order to entirely satisfy them.

masala mixing machine

50,000 Per Piece

1 Piece (MOQ)

Stainless Steel Liquid Mixing Tank

200,000 Per Piece

1 Piece (MOQ)

Ribbon Mixer Machine

360,000 Per Unit

1 Unit (MOQ)

high speed mixer machine

120,000 - 250,000 Per Piece

V Shape Blender Machine

150,000 - 950,000 Per Piece

1 Piece (MOQ)

Features Prime V mixer design is cGMP / GMP compliant All contact parts are made out of SS316 quality material. Maximum care has been taken to ensure safe operation of the unit. Safety reeling, overload protection and emergency shutdown features available. Mirror finish inside and outside the drum. Easy to load and unload the materials AC variable drive is provided for different speed.

Ss304/316 Milk Powder Blender

Get Price Quote

1 Unit (MOQ)

Double Cone Blender

Get Price Quote

Salient Features Ldeal for mixing of powders and homogeneous lubracation of granules. MOC SS 304/316/316L. Safety gusrds provided with limit switch interlocked to motor for higher capacity modal. Available capacities 5kg to 1000kgs. Automatic Loading & unloding facilites provided.