Colour Mixing Machine

50,000 Per Piece

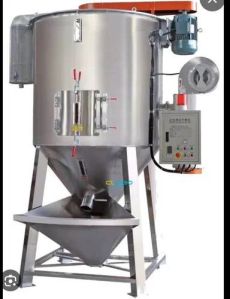

Granule Mixer Cum Dryer

120,000 - 225,000 Per Nos

1 NOS (MOQ)

Best Deals from Industrial Mixers

Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

Ribbon Blender

150,000 - 380,000 Per piece

1 piece (MOQ)

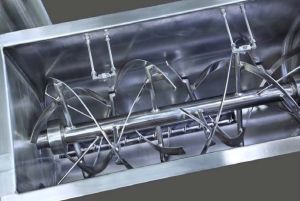

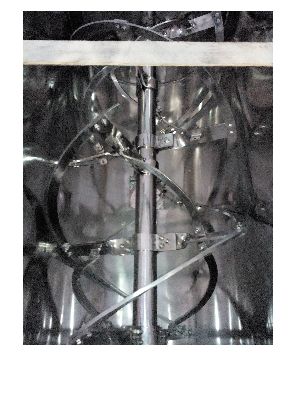

The RIBBON BLENDER is ribbon mixer machine widely used for the manufacture of dry powder, talcum powder, granules, spice and low-viscosity paste and liquid in chemicals, pharmaceuticals, food and cosmetics industries. It’s especially suitable for mixing solids with solids and solids with liquids, Approximate two third of the volume of the container of Ribbon Blender/mixer is filled to ensure proper mixing. Ribbon Blender mixer is Suitable for Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive, Chemical and Cosmetic products handling large Dry and wet powder volume. It consists of a horizontal “U” Vessel with horizontally installed shaft. Hexacon Enterprises make Horizontal Ribbon Blenders is an high efficient and versatile blending machines for mixing of dry powder, granule and viscous paste homogeneously. Ribbon blender mixer to given perfect r mixing due to the innovative designs of spiral agitators inside of its U-shape Cone chamber. Ribbon blender with Screw conveyor , ribbon blender with bin , ribbon blender with sifter , ribbon blender with product transfer input and output , liquid spray systems, working plat form with variable speed drive or PLC base operation we offer as per customer product and process , Horizontal ribbon mixers range from 50-25000L or more capacity as per requested by customer . Ribbon blender and mixer with stainless steel construction or Mild steel construction main body with stainless steel U shape mixer with bottom product discharge manual and auto valve , control panel , product bin etc we offering as per customer demand for wide industreis Food, Cosmetic, Waterproof Porcelain Glazed Polished Vitrified Tile Strong Adhesive, Floor Adhesive /Ceramic, Chemical, Plastic , Dry Powder, Putty, Modified Corn Starch, Real Stone Paint, Animal feed, Pharmaceutical, Fertilizer, Plastic, Battery etc…… We offer Quality with best mixer machines, mixing machine, blender, powder mixer manufacturers and suppliers by Shree Bhagwati Group of companies. RIBBON Mixers has been developed with advanced technology to achieve high blending capabilities and is among the most efficient machines in the market. The ribbon mixing equipment can be used in either the batch or continuous flow form to achieve an even and homogeneous blend in a wide range of products. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers. Capacity FROM 50 LITERS TO 15000 LITERS The ribbon blender machine comprises of a horizontal U shaped trough and a specially developed a double helical, fabricated ribbon agitator that rotates within the trough. The machine design is based on a proven agitator technology that efficiently achieves triple mixing action and ensures fast and efficient blending. The equipment dimensions and design of the operating parts are well balanced to provide balanced material movement within the container and avoids dead spots while rapidly discharging the product. The ribbon mixer machine is made with user friendly features such as wear resistance, corrosion resistant, vacuum filling and discharge arrangements, special shaft seals, heating and cooling jackets and in a variety of sizes and models for specialized applications. The operating capacity of the ribbon blender mixer ranges from 100 liters up to 8000 liters capacity, and it is constructed with stainless steel for maximum durability.

Stainless Steel Ribbon Blender Mixer

250,000 Per piece

1 piece (MOQ)

colour mixer

Get Price Quote

1 Piece (MOQ)

Details : Pneumatic raising of emulsionator unit. Horizontal swiveling Helical impeller with rotation in both directions Deflector disc adjustable in height All immerged parts made completely of SS. 304.

Vertical Mixer Machine

135,000 Per piece

1 piece (MOQ)

plough mixer

Get Price Quote

We offer plough mixer. We manufacture superior quality plough mixer that are used for different blending, mixing and drying processes. The machines provide perfect homogeneous blends for dry, fine as well as coarse powders, grains and pastes. These mixers find application in industries like pharmaceuticals, brake lining, cement, chemicals, cosmetics, dyes, fertilizers, foodstuffs, paints etc. Our range of plough mixers can be availed with optional jacket for cooling and heating applications.

Ribbon Mixer

Get Price Quote

Ribbon Blender

150,000 - 7,500,000 Per piece

1 Piece (MOQ)

High Speed Mixers

Get Price Quote

Moisture free blending and compounding with additives in different controlled temperatures Process control timer switch to set and monitor process Provision for on line additives or pigment adding facility and breather valves on the lid Thermo couple to monitor temperature Optional Pneumatic controlled powder discharge and lid opening arrangement Sturdy construction Stainless steel vessels (corrosion resistant) Twin jacket for heating and cooling Timer control for energy saving, Heavy duty bearing housing for trouble free working

Double Cone Mixer

Get Price Quote

This is a unique mixer which has 2 cones on the ends and cylindrical in the middle portion. It has two supporting legs. The shaft is moving with the cone by a motor and pedestal support which is mounted on legs. Both the cones have lids which can be opened or closed for loading and unloading. The double cones and cylindrical body is made of stainless steel. D.C. Mixer has two major functionsa. Mixing of the ingredients kept inside the chamber, andb. Hydration of the Guar splitIn guar-gum industry, the D.C. Mixer plays important role as it gives better result in fast hydration which enables to get better flaking, soft pulverising and high viscosity of the powder to be produced.

Pharmaceutical Mass Mixer

130,000 Per Piece

1 Piece (MOQ)

Mass Mixer

Get Price Quote

Salient Features: All contact parts are made of SS 304 (SS 316 optional) Thrust bearings are provided to carry rigid and thrust load. Easy for cleaning and operating. Interlocked acrylic dust cover for inspecting the mixing process. The tilting device provided for easy unloading of the material. Salient Features:- Mass Mixer - SS 304 Pharmaceutical Mixing Machine All contact parts are made of SS 304 (SS 316 optional) Thrust bearings are provided to carry rigid and thrust load. Easy for cleaning and operating. Interlocked acrylic dust cover for inspecting the mixing process. The tilting device provided for easy unloading of the material.

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

Incense Powder Mixing Machine

22,000 Per Piece

5 Piece(s) (MOQ)

Special Features : Contact parts made of customer requirement. Double Helical agitator with single speed for uniform dry mix and perfect wet mix. The general structure Ribbon Blender has non-contact parts made of customer requirement. The contact parts of the blender have a mirror finish.

Paddle Agitator

25,000 Per Piece

05 Piece (MOQ)

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

Ribbon Blender

Get Price Quote

Tablet Coating Machine, Rotary Tablet Machine

Mass Mixer

Get Price Quote

Specifications Of Mass Mixer: Shell: This Part Of Mass Mixer Consisting Of 'U' Trough Of Suitable Dimensions. Construction Of S.S. And Side Plates Duly M.S. Stiffened From Outside And From Inside With S.S. Mixing Mechanism: Paddle Type Blades Of Mass Mixer Is Welded To The Main Shaft Provide For Efficient Mixing Of Thick Heavy Material. PTFE Gland Mechanism Provided At Shaft Ends Prevents Ingress Of External Powder Into The Trough And Prevents Leakage. Charging: From The Top Charging Of The Mass Mixer Can Be Done Through A Hinge Able Lid, Hopper Or Nozzle Can Be Provided For Additional Spraying Of Additives Drive: This Part Of Mass Mixer Is Consisting Of Suitable H.P. TEFC 3 Phase Ac 415v / 50 Cycles Motor Coupled To Suitable Worm Gear, With Driving Shafts Mounted On Suitable Plummer Block. Mounting: Our Mass Mixer Is Mounted On Suitable ISMC Section Stand, With Protective Covers For Belts And Couplings MOC: All Contact Parts In S.S. Constructions. Complete Unit With S.S. Cover And All Surfaces Polished To Mirror Dull Finish. MS Parts Dull Painted To Smooth Finish. Options Available: The Control Panel Of Mass Mixer Is Mounted On Platform And Is Provided WithUnit In S.S. 316GMP Model With M.S. Parts Cladded With S.S.

High Shear Mixer

Get Price Quote

Rapid Mixer Granulator (High Shear Mixer) available from 25 Ltrs. (10 Kg. to 300 Kg. (600 Ltrs.) for the mixing of Raw Material, Powder with additional of Binding & also we can spray liquid also in running mixing products.

High Shear Mixer

Get Price Quote

The Prism compact LABOmix High Shear Mixer Granulator is a multi purpose processor equally suitable for high speed dispersion of dry powder, aqueous or solvent granulations and effervescent products and melts pelletization. Prism NewLABOmix-High Shear Mixer granulator series is characterized by the compact construction, modern design and the entire user and user friendly attributes which form the ergonomics design aspects are essential for a wide range of application. The overall concepts of the NewLABOmix steam from similar of process based on production model and common needs of consistent processing and ease for operation and cleaning. The mixing bowl designed with shallow and wide diameter for guarantee a consistent product vertex mixing by main impeller and granulated by chopper blade. A typical 3 minute dry mix operation than granulation by adding binder manually or spraying unit with pressurized. A free flowing granulate is produced after 3-5 minute and the granules are than rapidly discharge.

Pressure and Mixing Vessel

Get Price Quote

Our company is the trustworthy Manufacturer, Exporter and Supplier of Pressure and Mixing Vessel from Gujarat (India). Produced using top of the line quality basic material such as steel, aluminum, etc., our Pressure and Mixing Vessel is sturdy, durable and corrosion resistant. Also, our Vessel is known for its high performance. Talk of price, we are known all over the world for providing the best quality at the most discounted prices.

Mass Mixer Machine

Get Price Quote

APPLICATION : The mass mixture machine is specially made for the mixing of the dry and damp materials. The machine is very suitable to the tablet granulation. The machine is provided with powerful-geared drive and the mixing paddle make mass mixer. The machine is very efficiently mixing the material. It is proven an ideal mixture machine to mixing even the sticky ingredients. The two speed machine can customize as per requirement of the clients. CONSTRUCTION : The mass mixture machine provided by following components S.S. 304 mixing drum Mixing paddles Mixing drum body M.S. fabricated body carrying motor Gearbox starter The contact parts are of S.S.316 CONTACT PARTS : SS316 FEATURES : easy cleaning facility The transparent poly-carbonate dust cover with inter locking system. On opening of the cover, the machine stops functioning. The safety device is provided with the machine. To make easy unloading, the tilting device is provided with the machine. The machine is specially design to make self-adjusting sealing arrangement to ensure no black particles can enter into the mixing drum.

v cone blender

225,000 - 785,000 Per Piece

1 Piece(s) (MOQ)

Granules Mixing Machine

100,000 - 165,000 Per 100 kg to 150 kh

color dose mixer

65,000 - 70,000 Per NOS

Gyroscopic Mixer

Get Price Quote

1 Piece(s) (MOQ)

horizontal mixers

200,000 Per Set

Product Description:Our competency lies in manufacturing and supplying our clients an excellent quality range of Horizontal Mixer Machine. Use: Horizontal mixer machine is used for smashing raw materials Features: Superior functionality Sturdy construction High operational fluency

Ribbon Blender

560,000 Per Piece