masala mixing machine

50,000 Per Piece

1 Piece (MOQ)

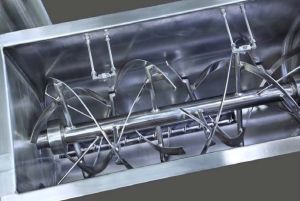

Ribbon Blender

150,000 - 380,000 Per piece

1 piece (MOQ)

The RIBBON BLENDER is ribbon mixer machine widely used for the manufacture of dry powder, talcum powder, granules, spice and low-viscosity paste and liquid in chemicals, pharmaceuticals, food and cosmetics industries. It’s especially suitable for mixing solids with solids and solids with liquids, Approximate two third of the volume of the container of Ribbon Blender/mixer is filled to ensure proper mixing. Ribbon Blender mixer is Suitable for Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive, Chemical and Cosmetic products handling large Dry and wet powder volume. It consists of a horizontal “U” Vessel with horizontally installed shaft. Hexacon Enterprises make Horizontal Ribbon Blenders is an high efficient and versatile blending machines for mixing of dry powder, granule and viscous paste homogeneously. Ribbon blender mixer to given perfect r mixing due to the innovative designs of spiral agitators inside of its U-shape Cone chamber. Ribbon blender with Screw conveyor , ribbon blender with bin , ribbon blender with sifter , ribbon blender with product transfer input and output , liquid spray systems, working plat form with variable speed drive or PLC base operation we offer as per customer product and process , Horizontal ribbon mixers range from 50-25000L or more capacity as per requested by customer . Ribbon blender and mixer with stainless steel construction or Mild steel construction main body with stainless steel U shape mixer with bottom product discharge manual and auto valve , control panel , product bin etc we offering as per customer demand for wide industreis Food, Cosmetic, Waterproof Porcelain Glazed Polished Vitrified Tile Strong Adhesive, Floor Adhesive /Ceramic, Chemical, Plastic , Dry Powder, Putty, Modified Corn Starch, Real Stone Paint, Animal feed, Pharmaceutical, Fertilizer, Plastic, Battery etc…… We offer Quality with best mixer machines, mixing machine, blender, powder mixer manufacturers and suppliers by Shree Bhagwati Group of companies. RIBBON Mixers has been developed with advanced technology to achieve high blending capabilities and is among the most efficient machines in the market. The ribbon mixing equipment can be used in either the batch or continuous flow form to achieve an even and homogeneous blend in a wide range of products. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers. Capacity FROM 50 LITERS TO 15000 LITERS The ribbon blender machine comprises of a horizontal U shaped trough and a specially developed a double helical, fabricated ribbon agitator that rotates within the trough. The machine design is based on a proven agitator technology that efficiently achieves triple mixing action and ensures fast and efficient blending. The equipment dimensions and design of the operating parts are well balanced to provide balanced material movement within the container and avoids dead spots while rapidly discharging the product. The ribbon mixer machine is made with user friendly features such as wear resistance, corrosion resistant, vacuum filling and discharge arrangements, special shaft seals, heating and cooling jackets and in a variety of sizes and models for specialized applications. The operating capacity of the ribbon blender mixer ranges from 100 liters up to 8000 liters capacity, and it is constructed with stainless steel for maximum durability.

Best Deals from Industrial Mixers

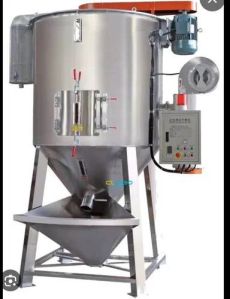

High Speed Heater Cooler Mixer

Get Price Quote

1 Piece (MOQ)

In a High speed mixer. the heat generated due to friction is utilised for mixing, hence it's known as "Heater mixer". High speed mixers are used to mix solid to solid. liquid and pasty components. The Heating phase in a heater mixer - It is not only the shortest possible cycle time which is the decisive factor, but in many cases. the way in which iriction is introduced in to the product is ol lar greater importance.Features of High Speed Heater-Cooler Mixer Stainless steel vessel Vessel-highly polished surface inside. discharge plate blended into bottom dish Mixing tools-sell cleaning. adjustable in height specific to the material being mixed. simple design. armoured leading edges Robust. easily serviced and maintained construction Twin jacket Corrosion and abrasion resistance No deposits, crusts or pockets ol colour Fest and complete discharge of the mixed material Easy and perfect cleaning Optimum adaptability to each type and size of mixing batch Optimum dispersion and distribution of components Improved tool life Quick. easy dismantling and reassembling Long service life Low noise level Short maintenance and repair times For heating and cooling purposes Optional Features Optional Features Chopper with separate Programmable logic control Additional device for dispersion. especially for soit mixes Optimum adaptability to the process requirements Constant high quality of the mixed material Application R PVC S PVC Master Batches Anti Fab Master Batches

Inline Powder Disperser

Get Price Quote

1 Piece (MOQ)

Homogenization, also know as particle size reduction or micronization is the process of reducing the particle size of molecules in order to facilitate disperser and emulsion. Inline homogenizers are positioned within the production line, and allow for continuous homogenization. These types of homogenizers are suitable for any size production volume, and are ideal for continuous processing of dispersions and emulsions. Capacities available from 1.0 HP to 30.0 HP with single stage to multi stage Rotor-Stator with slitted head, for greater shear action. Significant reduction of the chances of contamination. Product remains within a closed pipeline system. Work well with Clean In Place (CIP) systems. Easy to disassemble, clean, and maintain. Positively affect the aesthetics of the final product. Create stable and consistent emulsions and dispersions. Rapidly dissolve solid material and accelerate chemical reactions.

Mild Steel Ribbon Blender

50,000 - 500,000 Per piece

1 PIECE (MOQ)

Ribbon blender are used for all dry foods products, nutraceuticals, protein powder mixes, dry juice mixes, chemicals, fertilizer, insecticides, colorants, resins and polymers. The moderate shear of the ribbon or paddle naturally breaks down lumps and agglomerates. Ribbon blenders are extremely efficient and economical.

Incense Powder Mixing Machine

150,000 Per piece

1 piece (MOQ)

Stainless Steel Jacketed Mixing Tank

200,000 - 300,000 Per piece

01 piece (MOQ)

Ribbon Mixer Machine

360,000 Per Unit

1 Unit (MOQ)

Mixing Machine For Raw Material(Granules)

80,000 - 150,000 Per piece

1 piece (MOQ)

Stainless Steel Mixing Vessel

160,000 Per Piece

1 Piece (MOQ)

Stainless Steel Bin Blender

100,000 Per Piece

1 Piece (MOQ)

high speed mixer machine

120,000 - 250,000 Per Piece

masala mixing machine

21,400 - 191,900 Per piece

Mixing Vessel

150,000 - 395,000 Per Piece

1 Piece (MOQ)

Mass Mixer Machine

95,000 - 750,000 Per Piece

1 Piece (MOQ)

Features : High speed, easy to operate machine. High grade SS 304 body and components. Contact parts are made of SS 316. Compact design enables the Prime Mass Mixer to occupy smaller floor space. Transparent dust cover to prevent dust and contamination. Easy to clean and maintain. Tilting Device is provided for easy unloading material.

Vertical Mixer Machine

135,000 Per piece

1 piece (MOQ)

Paddle Type Agitator With Support

Get Price Quote

40 Piece (MOQ)

Ribbon Blender Mixer machine

250,000 Per Piece

1 Piece (MOQ)

Radial Agitator

Get Price Quote

1 Piece (MOQ)

ABS Submersible Mixers

Get Price Quote

10 piece (MOQ)

ABS RW is Sulzer’s standard range of Submersible Mixer Features Compact & Reliable water pressure-tight Design Reduced energy cost Shorter Mixing time Patented solid deflection ring Blockage free propeller Direct drive or Geared motor Easy installation Hazardous location ATEX compliant for inflammable gases Range RW 200 to RW 900 Support for Sizing and design for each installation with the help of computer software ABS has world wide installation. In India since 2005 and have a huge installation base