Three Phase Helical Geared Motor

Get Price Quote

1 Piece (MOQ)

FOOT BASE VIBRATORS MOTORS

Get Price Quote

Foot Base Mounted Motor Sonal has a wide range of FOOT BASE VIBRATORS MOTORS to meet the requirement of various industries where in material handling plays a major role. These vibrators help to empty, dose, convey, loosen, test, clean, screen, compact, distribute, feed etc., & therefore have a very wide application in Mining, Fertilizer, Chemical, Parma & Food Industry etc Sonal-FOOT BASE VIBRATORS MOTOR vibrators Motors are robust, reliable, highly loadable, quite running and require no maintenance are totally enclosed, surface cooled units operating 415 / 440 volts, 3 phases, 50 cycles. A.C. Supply. Generously dimensioned cylindrical roller bearing, self-lubricating maintenance-free, long life expectancy. The vibrating frequency depends on the revolutions of the rotary unit & can be chosen from four ranges available via, frequencies are 3000, 1500, 1000, 750 vibrations per minute. When used as a single unit, they impact circular vibrations. If directional vibrations are needed, two vibrators running in the opposite direction should be use. The Centrifuge force can be adjusted from zero to maximum by manipulating the relative positions of the eccentric weights provided on either side of the shaft. Various models are available giving a wide choice of Centrifugal force, frequency of vibration, mounting position, Insulation etc. The customer is therefore assured of getting the most suitable vibrator to meet these requirements.Salient Features: Sturdy & robust construction. Totally enclosed dirt & dust proof construction. Amplitude of vibration can be controlled. Heavy-duty bearings for long & trouble free operation. Centrifugal force can be adjusted from zero to maximum. Low noise as compared to Electromagnetic Vibrators. Low maintenance due to absence of belts, pulleys, chains sprockets etc. Application in various industries: Construction industry Industry of building materials Mining industry Chemical industry Packaging and food industry Mechanical engineering Application techniques: Compaction Transport Evacuation / emptying Screening / grading Draining Dosing Deaerate Distribution Sizing / sorting Dust collection Loosen up of bulk materials Center Flanged Motor Sonal has a wide range of CENTER FLANGED VIBRATORS MOTORS with flange fixation, covering all the applications needs on vibrating equipments for screening, finishing, drying and other processes that use vibrating motors with this fixing system. SONAL-CENTER FLANGED VIBRATORS MOTORS are robust, reliable, highly loadable, quite running and require no maintenance are totally enclosed, surface cooled units operating 415 / 440 volts, 3 phases, 50 & 60 cycles. A.C. Supply. Generously dimensioned cylindrical roller bearing, self-lubricating maintenance-free, long life expectancy. The vibrating frequency depends on the revolutions of the rotary unit & can be chosen from four ranges available via, frequencies are 3000, 1500, 1000, 750 vibrations per minute. The Centrifuge force can be adjusted from zero to maximum by manipulating the relative positions of the eccentric weights provided on either side of the shaft. Various models are available giving a wide choice of Centrifugal force, frequency of vibration, mounting position, Insulation etc. The customer is therefore assured of getting the most suitable vibrator to meet these requirements. Three Phase Input Voltage: Standard executions 50Hz 220-230/380-400V , 60Hz 220-240/440-480V (for series EVR-EVS 50Hz 380-400V; 60Hz 440-480V). Special input voltages available on request. Speed (vibrations/minute): Standard: 2 poles: 3000 rpm - 50Hz 3600 rpm - 60Hz 4 poles: 1500 rpm - 50Hz 1800 rpm - 60Hz 6 poles: 1000 rpm - 50Hz 1200 rpm - 60Hz On Request: Speeds not listed as standard two speeds motors 3000/1500rpm or 1500/1000rpm Duty Continuous duty at the maximum centrifugal force (S1), with the possibility to adjust the force from 0 to 100% following the specific graded plate on the eccentric weights (for those series/models supplied by OMB complete with weights). Electric Motor Electric motor realized with low loss silicium magnetic lamination core allowing increasing the efficiency while reducing heating up. Insulation Class : F standard, H on request. Tropicalisation: Windings impregnation realized with ASTM system, with polyester resin class H. Ambient Temperature: From -20°C a +40°C (-4°F/104°F). Overheating Protection: Electric motor protected by Thermistor (PTC set at 130°C) as standard for sizes 50 and 70 (available on request on smaller sizes). Motor Shaft: Shafts in NiCrMo steel, heat treated. Main Body: Mechanical structure designed to withstand the high stresses, realized in cast iron high resistance Painting: Electrostatic powder painting, epoxy-polyester, polymerized in oven. Color: Blue RAL 5010. Bearings and Lubrication: High load capacity bearings, in special executions to withstand the stresses of high centrifugal forces and vibrations, over-dimensioned to grant maximum reliability in vertical use. Special “Long Life” grease lubrication. Mechanical seals with low friction to grant excellent protection, without over-heating and without extra power absorption, keeping their efficiency for long time. Some models as a standard, others on request, are provided with bearing housing with double lubrication entry, to grant that lubrication grease inlet is always from upper side of the bearing.

Best Deals from Industrial Motors

electric brake motor

7,900 Per Piece

Submersible Pump Motor

Get Price Quote

Being a prominent name in this area of operations, we, as a Supplier, bring forth qualitative array of Submersible Pump Motor. Our payment procedure is not only easy but also safe ensuring your long-term reliance upon us. Whether it is online payment procedure, cash, bank deposits or others, we are here to guide you throughout the process. Feature : 0.5 hp Copar rotor

Four Water Filled Submersible

Get Price Quote

Varuna Submersible Motors are manufactured as per IS: 8034 Standard. These sturdy and robust submersible motors are made using advanced technology. All parts are manufactured and fitted precisely using CNC machine that imparts excellent mechanical strength and reliability. Salient Features Induction motors are easily re-windable using multi layer PVC insulated wire for better reliability. Motor filled with water gives better cooling to winding as well as bush. Self-aligned carbon Stainless steel thrust bearing which withstands high axial thrust load in water lubrication. Electrically designed to lower power consumption and operating cost. Non-magnetic, corrosion-resistant high-grade stainless steel stator body. Water-filled motor is available in capacitor start and run design. Gun Metal bush is made with additional centrifugal molding process and 2 % Nickel is added. Superior designed Noryl impellers and diffusers give higher hydraulic performance and greater efficiency and provide higher resistance against wear and tear from sand and other impurities. Stainless steel strainer prevents particles over a certain size from entering the pump. Pumps are available with non-return valve to reduce the backpressure of water when they are switched off. Impeller and Bowl are accurately machined by CNC machine to ensure high dimension accuracy. Rubber bush and SS hard chrome sleeve increase wear-resistance against sand. Lightweight, compact and robust construction design. Application Sprinkler and drip irrigation Civil and industries Fire fighting system Agriculture

Single Phase AC Synchronous Motor

500 Per Piece

20 Piece(s) (MOQ)

DC Solar Submersible Motor

16,500 Per Piece

Induction Motor

Get Price Quote

Crane Duty Brake Motor

6,000 - 50,000 Per Piece

CNC ATC Spindle Motor 7.5 kW,11000 RPM,380 V,BT40

225,000 Per 1

1 Piece (MOQ)

Suitable for machining aluminium, plastic and light alloys Greater Stability even at Higher RPMs (Even at 60000 rpm) Tool Changing facility Cycle time reduction

Flame Proof Motors

Get Price Quote

range : the motors are available from 63 to 315 and in 2 pole to 16 pole design. applications : flame proof ( explosion proof or increased safety)motors suitable for zone 1 and zone 2 areas for gas group I , iia , iib and iic are approved by cmri , ccoe , bis and dgms ( iic on request only) features brake motors , coolingtower motors. double shaft , special shaft. multi speed. dual voltage / dual frequency crane duty / lift duty suitable for s1 to s9 , duty different c.d.f. And various no of starts / stops / reversals. suitable for different service factors. suitable for vvvf operation nema and iec frames. ii c flame proof motors of full range (63-280 frames).

electric brake motor

10,500 - 96,500 Per Pieces

1 Pieces (MOQ)

Siemens Crane Duty Motor

7,410 Per Piece

Three Phase Electric Motor

Get Price Quote

We are the leading Suppliers and Exporters of Three Phase Electric Motor. Our well-reputed entity is based in Gujarat, India. We obtain it from our reliable vendors, who use the superior quality components and updated techniques for manufacturing it. Our offered Three Phase Electric Motor is known for its optimum functionality, efficient performance, robust structure, and long operational life. We make sure that it is in accordance with the set industrial standards and norms.

Electric Single Phase Motor

Get Price Quote

1 Piece(s) (MOQ)

Size: 11.5235 H.P. Maya Flour Mill

Cooling Tower Motors

Get Price Quote

We hold expertise in trading and supplying a superior quality range of Cooling Tower Motors. Manufactured employing advanced technologies and latest machines; these products are used in cooling towers of air conditioning and refrigeration industries & plants. Post-procurement, our quality controllers inspect these products on certain parameters of quality to ensure their flawlessness.

Single Phase Electric Motors

Get Price Quote

Single-phase motors are suitable for applications in domestic, commercial, entertainment, scientific, industrial fields, powering small type machine tools and water pumps. These motors are integrated with up-to-date design, built with the best quality materials with outstanding performance, easy maintenance and reliable running.

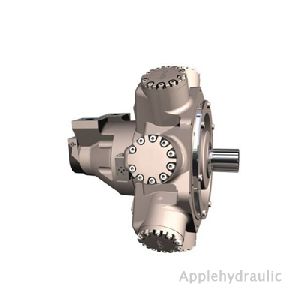

Dual Displacement Radial Piston Motor

Get Price Quote

Three Phase Motors

Get Price Quote

We are proud to present a splendid range of Three Phase Motors, which is highly favored by our clients for its longer service life. Manufactured using high grade stainless steel & aluminum and fabricated employing cutting-edge technology, these products exhibit exceptional durability and functioning. These motors are widely preferred in comparison with single-phase motors as these provide power to large industrial loads with optimal efficiency. Available at competitive prices, these are one of the highly demanded products in the market.Its competitive advantages are as follows:Long lasting performanceRugged designEasy installation

Lift Gear Motor

5,500 Per Piece

orbital motor

8,000 Per Piece

Gear Brake Motor

75,000 Per Piece

02 Piece (MOQ)

Vibratory Motors

Get Price Quote

Our product, Vibratory Motors known for their superior quality, smooth finish, reliability, energy-efficiency, and ease-of-operation. Also, our product have proved its usages in various industries owing to its excellent performance and durability.Features: Manufactured using finest quality material Smooth finish Minimal maintenance Reliability Energy-efficiency Ease-of-operation High performance Durability

Spindle Motors

Get Price Quote

Our spindle motor have ciramic ball bearing for better life and performance.JDS Spindle Motor is widely used in cnc router and cnc milling machine.

Vibratory Motor

Get Price Quote

SHREENATH Vibratory motors are Robust, Reliable, High Loadable Quiet Running and require no maintenance.SHREENATH Vibratory motors are totally enclosed 3 Phase, Squirrel cage induction motors with adjustable, eccentric weights mounted at both the ends of the shaft, to set up vibrations during rotation. The design of shaft and the selection of bearings has been carefully done to withstand heavy radial loads. APPLICATION These motors are used in various material handling equipments such as vibrating screens, conveyors, and feeder. They are also used on hoppers, silos to prevent congestion of material flow. Foundry shake - outs and compacting machines use these motors for fast and efficient operation.

Cooling Tower Fan Motor

Get Price Quote

Concept: These motors specially design for cooling tower Fans for continues running in humidity area. Range: Our cooling tower motor range 0.25 to 20 hp. Frame 71 to 225M.Motors are flange mounting with IP-55 Degree of protection. Supply 415(+- 5%) voltage and frequency 50Hz. (+-3%) combined +-5%.Motor available in 4, 6, 8, 10 and 12 pole. on customer request we are also able supply motor in 220, 380, 460, 525 volts on HZ. 50 or 60.Performance: Motor performance conforms to IS: 325.Mounting: Mounting V1 shaft downward position Flange B-5 as per IS 2223.Duty & Insulation: Insulation class “F” with constant duty (s1) Cooling tower motor design for Working S1Duty. For continues working. Motor relative humidity up to 90%Shaft and Bearing: Our cooling tower Motor relative humidity up to 90%.Cooling tower Motor Shaft is Mead by stainless steel material AISI-410. Nut and washer are made for stainless steel AISI-202. It can make protection against corrosion. Motor shaft extended so cooling fan fitted properly.

Single Phase Motors

Get Price Quote

We are the prominent Manufacturer and Supplier of Single Phase Motors in India. Our Single Phase Motors are fabricated as per the set industry standards to fulfill the variegated demands of clients. Our range of Single Phase Motors is highly acknowledged in the Indian market for its energy efficiency and some exceptional features such as robust construction, corrosion resistance, and low maintenance.

Industrial Gear Motor

5,500 Per Piece

By utilizing our years of experience and in depth knowledge of this domain, we bring forth a qualitative array of Industrial Gear motor. Product Description: 0.5 Hp 1 minutes 80 rpm Features: : Efficient usage Precisely engineered Long service life

Single Phase AC Synchronous Motor

Get Price Quote