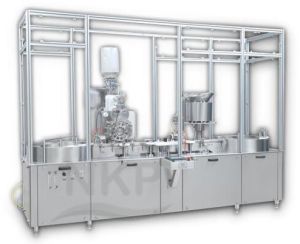

Automatic Injectable Powder Filling with Rubber Stoppering Machine

800,000 Per Piece

1 Piece (MOQ)

Automatic Injectable Dry Powder Vial Filling Machine

Get Price Quote

1 Unit (MOQ)

Best Deals from Injectable Dry Powder Filling Machine

Automatic Injectable Dry Powder Filling Machine

Get Price Quote

Salient Features: Total cGMP Model. Total contact parts are of S.S. 316, and other surface parts are of S.S. 304. Automatic speed control system. “NO VIAL – NO FILLING SYSTEM “Which reduce the wastage of costly powder. As the Machine is attached with Rubber Stoppering unit, it reduces the space in sterile area & finally the space of laminar flow unit. Multiple dosing systems – with the help of change parts. High accuracy for filling costly powder – (+ or -) 1%. All contact parts are easily removable all sterilization. Elegantly matt finished body. Inbuilt protection against over current, Voltage fluctuation, Short circuit in. Standard in quality & economical in price.

injectable dry powder filling machine

1,200,000 Per Pack

injectable dry powder filling machine

Get Price Quote

Total Table top cGMP model. “NO VIAL, NO FILL” System eliminates wastage of costly powder. Spring loaded Teflon top seal for powder hopper reduces the friction between and top seal and avoid chance of white particle shading during production. Doctor blade and wiper blade can be adjusted from outside also without disturbing any production, which saves lot of time, powder wastage and chances of area condition disturbance. All assemblies under top plate are positioned as for easy cleaning or maintenance. Multiple dosing of injectable powder or changeover of container size and different fill size is possible by just changing the vial separator or size of the piston respectively. All driving is through High quality Gear motor for better machine performance without vibration or leakage of oil of area floor from gear box. Machine speed can be adjusted through A.C. Frequency drive, which is time saving and easy to synchronise unscrambler and scrambler speed with machine speed. Machine is provided with delrin conveyor belt to avoid sticking of vial on conveyor. Special clutch devices are provided on vial separator for safety purpose. Vibratory bowl for rubber stoppering unit support to run machine with total claimed speed of machine. Vacuum filter will be of PVC transparent material with nylon cartage having length of 10”. Pure air filters for Air and Vacuum.

Double head Injectable Dry Powder Filling Machine

Get Price Quote

Double head Injectable Dry Powder filling machine with rubber stoppering machine is capable to delive output at higher speed in pharmaceutical companies. Salient Feature of Machines: Double head Injectable Dry Powder filling machine with rubber stoppering machine is equipped with following features: A CGMP Model. Production output up to 240 Vial per minute. "NO VIAL, NO FILL” System eliminates wastage of costly powder. Works on combination of Vacuum pressure dosing system which in turn reduces residual powder at the end of the batch to a minimum. Facility of Simultaneous adjustment of dosing port volume. Simple, fast & repeatable changeover. Positive vial transport i.e starwheels guide the vials through the filling, stoppering stations,ensuring they remain upright and guaranteeing correct placement. All contact parts i.e Parts come in contact with powder are made of SS316 material with easy removal system for Autoclaving / Sterilization. Hopper can be completely dismental for easy cleaning All assemblies under top plate are positioned as for easy cleaning or maintenance. M ultiple dosing of powder or changeover of container size and different fill size is possible by just changing the vial separator or size of the piston respectively. Special clutch devices are provided on vial separator as well as stoppering station for safety purpose. Vacuum filter will be of PVC transparent material with nylon cartage having length of 10”. No Stopper in Chute, Machine Stop System. Power supply 415 Volts, 3 Phase (4 wire System) 50 Hz With Neutral & Proper Earthing thru CVT or Servo Stabilizer (in customer’s scope) Vacuum Line 800 mm hg (9/10 cfm)Nozzle Dia. 6.5 (Flexible Tube Connect with Clamp) (in Supplier scope) Air Line Filtered, Oil Free sterile low-pressure air or inert gas at 2 kg. cm² pressure (8/9 cfm)Nozzle Dia. 6.5 (Flexible Tube Connect with Clamp) (in Supplier scope)v

utomatic Injectable Dry Powder Filling with Rubber Stoppering Machine

Get Price Quote

We offer utomatic injectable dry powder filling with rubber stoppering machine. Model no. nkpf - 150dp direction left to right production rate up to 120 fillsmin. For single dose. Up to 60 fillsmin. For double dose. Up to 40 fillsmin. For triple dose. Up to 30 fillsmin. For four dose. Fill capacity 50 mg to 1.5 grms. Single dose (with change parts), 1.5 grms. To 6 grms. Double, triple and four dose. Fill range depending upon vial opening and bulk density of powder. Accuracy ±1% depending upon consistency and the uniformity of bulk density of injectable powder under controlled level of humidity (i.e. 25%). Electrical supply 7.0 hp power requirement 415 volts, 3 phase (4 wire system), 50 hz.

injectable dry powder filling machine

Get Price Quote

Injectable Powder Filling & Stoppering Machine Model – LPFS 100. The Basic Unit Consists Of One side Turn Tables, S.S. Slat Conveyor Belt, Unique powder wheel.The Machine Can Be Run Totally Through Touch Screen HMI, PLC Control And The Machine Is Based On Servo Motor Drive, The Machine Has an Output Speed of 120 Vials per Minute but Depending upon the Fill Volume and Container Dia. size Or the Quality of Powder

Automatic Injectable Dry Powder Vial Filling Machine

300,000 Per UNIT

1 Piece (MOQ)

automatic injectable dry powder vial filling machine – jdm pharmatech’s line of products has been created to match the pharma industry’s needs. we are one of the leading manufacturer and supplier of injectable dry powder filling machines in ahmedabad. our automatic injectable vial filling machine has been designed for automatic filling of dry powder in the vial. this is a completely automatic machine that has been designed as per the industry standard and matches quality specifications. our machine has a varied capacity to fill 20 or 240 vials per minute, thereby enhancing the entire process. besides, our automatic injectable dry powder filling machine is equipped to fill 5 ml to 30 ml vial (without replacing change parts). the machine also places the rubber stopper on the vial to prevent any kind of contamination. this machine is highly workable as it assures satisfactory performance. this dry powder filling machine is highly durable and made to last long, even in a longer work cycle without technical breakdown. we are one of the leading injectable dry powder filling machine manufacturers in india. our state of the art technology and round the clock customer support has made us the leading choice of dry powder filling machine supplier in india. if you want to place an order for a dry powder vial filling machine, and are looking for the best dry powder filling supplier in ahmedabad or india, then we are your trustworthy partner.

injectable dry powder filling machine

Get Price Quote

The Automatic Injectable Powder Filling with Rubber Stoppering Machine Model DRYFILL-120i, is suitable for Round Vials with maximum speed of 120 Vials per minute. Specially Machine construction in fully Stainless Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Powders are made from Ss316 Materials.

Automatic Injectable Dry Powder Filling with Rubber Stoppering Machine

Get Price Quote

Direction Left to Right Production Rate Up to 120 Fills/Min. for single dose.Up to 60 Fills/Min. for double dose.Up to 40 Fills/Min. for triple dose.Up to 30 Fills/Min. for four dose. Fill Capacity 50 Mg to 1.5 Grms. single dose (with help ofchange parts).1.5 Grms. to 6 Grms. double, tripleand four dose. Fill range depending upon vialopening and bulk density of powder. Accuracy ± 1% depending upon consistency and theuniformity of bulk density of injectable powderunder controlled level of humidity (i.e. 25%). Electrical Supply 5.0 HP Power Requirement 415 Volts, 3 Phase (4 Wire System), 50 Hz. Height of Conveyor Adjustable from 900 to 950 MM Dimensions 3028 MM (L) x 1093 MM (W) x 1885 MM (H) Net Weight 800 Kgs. (Approx) Gross Weight 1200 Kgs. (Approx) Fill sizes 50 mg. to 6 grms Vial Sizes 5 ml. to 30 ml. Rubber Stopper Sizes 20 mm

injectable dry powder filling machine

Get Price Quote

Direction Left to Right Production Rate Up to 240 FillsMin. for 10 ml. Vial Fill Capacity 50 Mg to 1.5 Grms. single dose (with help of change parts), 1.5 Grms to infinite number of doses. Fill range depending upon vial opening and bulk density of powder. Accuracy ± 1% depending upon consistency and the uniformity of bulk density of injectable powder under controlled level of humidity (i.e. 25%).

Injectable Dry Powder Filling Rubber Stoppering Machine

Get Price Quote

Automatic visual vial inspection machine