Venturi Ball Float Steam Traps

5,000 - 20,000 Per piece

1 Piece (MOQ)

IEPL Steam Traps come standard with our 10 year performance guarantee against orifice erosion and steam wastage . See below the smooth steam flow in IEPL Steam trap compare to other mechanical steam trap. Due to the traps unique orifice design there is TRUE continuous condensate discharge without any open/close cycles rather than intermittent discharge unlike traditional mechanical type steam traps. It is important to know that acceptable loss from 50 Rectus steam traps is LESS than that of 1 failed open mechanical type steam trap. And CO2emissions are reduced through reducing steam consumption and boiler fuel usage by up to 20%. Benefits No moving parts No spare parts required Permanently eliminate the need for steam trap surveys & repairing cost. Environmentally Friendly Save water Save water treatment chemicals Save electricity Handles varying or constant loads Easily handles water hammer Automatic air venting at start-up Perfect operation in vertical or horizontal installation.

Country of Origin : India

Size : 1.1/2inch,1.1/4inch,1/2inch,1inch,2inch,3/4inch

Type : Steam Traps

Brand Name : IEPL

Material : Stainless Steel,IEPL

Certification : IEPL

Application : Water Fitting

Color : Water Fitting

Feature : Casting Approved,Corrosion Proof,Investment Casting

Condition : New

Pressure : High,Medium

End Connection : Screwed

Number Of Way : Screwed

...more

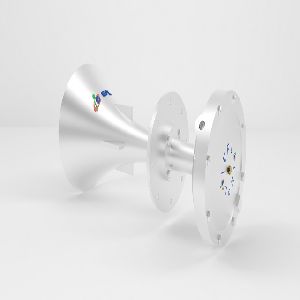

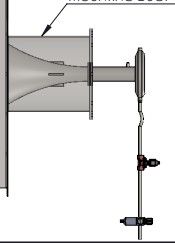

Super Heater Zone Sonic Soot Blower

40,000 - 110,000 Per Pieces

1 Piece (MOQ)

Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system. Sonic Soot blower is based on the principle of kinetic activation of the dust particles. The sound generator sent out powerful sound signals, of low frequency & high intensity, at suitable intervals, inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces. These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas. It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter. It applicable at Package Boilers, Water tube boilers, Waste heat recovery boiler, Super heaters, Economisers, Air Heaters, Gas Heat Exchanger, Bag houses, Electrostatic Precipitators, fans, Soils, Hoppers & Ductwork.Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Color : SILVER

...more

Steam Traps

5,000 - 20,000 Per piece

1 Piece (MOQ)

IEPL Steam Traps come standard with our 10 year performance guarantee against orifice erosion and steam wastage . See below the smooth steam flow in IEPL Steam trap compare to other mechanical steam trap. Due to the traps unique orifice design there is TRUE continuous condensate discharge without any open/close cycles rather than intermittent discharge unlike traditional mechanical type steam traps. It is important to know that acceptable loss from 50 Rectus steam traps is LESS than that of 1 failed open mechanical type steam trap. And CO2emissions are reduced through reducing steam consumption and boiler fuel usage by up to 20%. Benefits No moving parts No spare parts required Permanently eliminate the need for steam trap surveys & repairing cost. Environmentally Friendly Save water Save water treatment chemicals Save electricity Handles varying or constant loads Easily handles water hammer Automatic air venting at start-up Perfect operation in vertical or horizontal installation.

Country of Origin : India

Size : 1/2inch, 1inch, 2inch, 3/4inch, 4/5inch

Type : Steam Traps

Material : Stainless Steel

Feature : Casting Approved, Corrosion Proof, Good Quality, Investment Casting

Condition : New

Pressure : High, Medium

End Connection : Screwed

Brand Name : IEPL

...more

Steam Trap

2,222 - 10,000 Per Piece

Benefits : Minimal Maintenance No moving parts No spare parts required Permanently eliminate the need for steam trap surveys Savings on labour for repairing steam traps Unaffected by thermal shock or water hammer Environmentally Friendly CO2 emissions are reduced through reducing steam consumption and boiler fuel usage by up to 20% Save water Save water treatment chemicals Save electricity Handles varying or constant loads Easily handles water hammer Automatic air venting at start-up Perfect operation in vertical or horizontal installation

Size : Standard

Material : Stainless Steel

Certification : ISI Certified

Application : Industrial

Color : Grey

End Connection : Flanged, Screwed

...more

SS Steam Trap Valve

6,000 - 25,000 Per piece

1 Piece (MOQ)

IEPL Steam Traps come standard with our 10 year performance guarantee against orifice erosion and steam wastage . See below the smooth steam flow in IEPL Steam trap compare to other mechanical steam trap. Due to the traps unique orifice design there is TRUE continuous condensate discharge without any open/close cycles rather than intermittent discharge unlike traditional mechanical type steam traps. It is important to know that acceptable loss from 50 Rectus steam traps is LESS than that of 1 failed open mechanical type steam trap. And CO2emissions are reduced through reducing steam consumption and boiler fuel usage by up to 20%. Benefits No moving parts No spare parts required Permanently eliminate the need for steam trap surveys & repairing cost. Environmentally Friendly Save water Save water treatment chemicals Save electricity Handles varying or constant loads Easily handles water hammer Automatic air venting at start-up Perfect operation in vertical or horizontal installation.

Country of Origin : India

Size : 1.1/2inch, 1.1/4inch, 1/2inch, 1inch, 2inch, 3/4inch, 4/5inch

Type : Steam Traps

Material : Stainless Steel

Application : Water Fitting

Feature : Casting Approved, Corrosion Proof, Good Quality, Investment Casting

Condition : New

Pressure : Medium

End Connection : Screwed

Brand Name : IEPL

...more

SS MECHANICAL CONDENSATE RECOVERY PUMPS

70,000 - 200,000 Per Set

1 Piece (MOQ)

presently in some of industry, condensate is collected in the collection tank and there after it is being pumped by conventional electrically operated centrifugal pumps. in this process 15-20° c temperature reduce as it is stored in collection tank. while in boiler condensate pump condensate water is pumped as soon as it is filled. so there is not significant temperature drop. electrical pump require frequent maintenance, while boiler condensate pump have only float type moving part which is fit and forgot type. electrical pump faces the problem of dry running due to high vapour pressure while boiler condensate pump will never have these problems. electrical pump faces the cavitations and pitting problems while boiler condensate pump will never have this problem. features 1. boiler condensate pump having no moving part assured zero maintenance. 2. boiler condensate pump utilise of flash steam. 3. boiler condensate pump suitable for high temp. application. no cavitations problem 4. in condensate recovery pump less steam consumption at low pressure. 5. boiler condensate pump can be operated on compressed air. 6. boiler condensate pump automatic venting of air & non - condensable gases 7. easy monitoring of boiler condensate pump operation can be checked in sight glass. 8. boiler condensate pump of various sizes for different capacities.( max. cap.12,000 kg/hr ) 9. boiler condensate pump skid mounted so easy to install. application : boiler condensate pump use for tracing line, radiator, cyclinder, dryer, heat exchanger, vessels, jacketing, oven, heating tank condensate recovery pump use for industries like pharma, textile, automobile, petro chemical, paper mill, sugar mill, processing unit, chemical etc…

Type : CONDENSATE RECOVERY PUMP

Application : Steam Boiler Plants, BOILER

Color : Blue

Power : Pneumatic

Country of Origin : India

...more

SONIC SOOT BLOWER FOR THERMIC FLUID

35,000 - 75,000 Per Piece

1 Piece (MOQ)

Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system. Sonic Soot blower is based on the principle of kinetic activation of the dust particles. The sound generator sent out powerful sound signals, of low frequency & high intensity, at suitable intervals, inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces. These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas. It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter. It applicable at Package Boilers, Water tube boilers, Waste heat recovery boiler, Super heaters, Economisers, Air Heaters, Gas Heat Exchanger, Bag houses, Electrostatic Precipitators, fans, Soils, Hoppers & Ductwork.Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Type : Soot Blowers,Sonic Soot Blower

Application : Soot Blowing

Weight : 100-1000kg

Color : Silver

Voltage : 220V

Condition : New

Warranty : 1year

Country of Origin : India

Automation Grade : Fully Automatic

...more

SONIC SOOT BLOWER FOR SUPERHEATER ZONE

50,000 - 80,000 Per Piece

1 Piece (MOQ)

Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system. Sonic Soot blower is based on the principle of kinetic activation of the dust particles. The sound generator sent out powerful sound signals, of low frequency & high intensity, at suitable intervals, inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces. These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas. It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter. It applicable at Package Boilers, Water tube boilers, Waste heat recovery boiler, Super heaters, Economisers, Air Heaters, Gas Heat Exchanger, Bag houses, Electrostatic Precipitators, fans, Soils, Hoppers & Ductwork.Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Type : Soot Blowers,Sonic Soot Blower

Application : Soot Blowing

Weight : 100-1000kg

Color : Silver

Voltage : 220V

Condition : New

Warranty : 1year

Country of Origin : India

Automation Grade : Fully Automatic

...more

Sonic soot blower for ESP

35,000 - 120,000 Per Set

1 Piece (MOQ)

Sonic Soot blower for thermal power plant based on the principles of kinetic activation of dust particles using sound waves at low frequencies that are normally between 75-240 Hz 140 db high intensity. The sound waves are generated by a special bell shaped sound generator powered by air and controlled electrically by a solenoid valve. The kinetic energy imparted to the dust particles cause them to vibrate, break their bonds with other particles and the surface to which they cling. These fluidized particles are then dispersed by gravity or by gas stream pressure.

Type : Soot Blowers

Application : Soot Blowing

Weight : 100-1000kg

Color : Silver

Condition : New

Driven Type : Pneumatic

Warranty : 1year

Country of Origin : India

Automation Grade : Fully Automatic

...more

SONIC SOOT BLOWER FOR ECONOMISER

35,000 - 120,000 Per Set

1 Piece (MOQ)

Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system. Sonic Soot blower is based on the principle of kinetic activation of the dust particles. The sound generator sent out powerful sound signals, of low frequency & high intensity, at suitable intervals, inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces. These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas. It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter. It applicable at Package Boilers, Water tube boilers, Waste heat recovery boiler, Super heaters, Economisers, Air Heaters, Gas Heat Exchanger, Bag houses, Electrostatic Precipitators, fans, Soils, Hoppers & Ductwork.Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Type : Soot Blowers,Sonic Soot Blower

Application : Soot Blowing,

Weight : 100-1000kg

Color : Silver

Condition : New

Warranty : 1year

Country of Origin : India

Automation Grade : Fully Automatic

...more

SONIC SOOT BLOWER FOR CEMENT SILOS

75,000 - 1,200,000 Per Set

1 Piece (MOQ)

Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system. Sonic Soot blower is based on the principle of kinetic activation of the dust particles. The sound generator sent out powerful sound signals, of low frequency & high intensity, at suitable intervals, inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces. These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas. It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter. It applicable at Package Boilers, Water tube boilers, Waste heat recovery boiler, Super heaters, Economisers, Air Heaters, Gas Heat Exchanger, Bag houses, Electrostatic Precipitators, fans, Soils, Hoppers & Ductwork.Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Type : Soot Blowers,Sonic Soot Blower

Weight : 100-1000kg

Condition : New

Warranty : 1year

Country of Origin : India

Automation Grade : Fully Automatic

...more

SONIC SOOT BLOWER FOR BOILER

40,000 - 110,000 Per Set

1 Piece (MOQ)

Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system. Sonic Soot blower is based on the principle of kinetic activation of the dust particles. The sound generator sent out powerful sound signals, of low frequency & high intensity, at suitable intervals, inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces. These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas. It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter. It applicable at Package Boilers, Water tube boilers, Waste heat recovery boiler, Super heaters, Economisers, Air Heaters, Gas Heat Exchanger, Bag houses, Electrostatic Precipitators, fans, Soils, Hoppers & Ductwork.Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Type : Soot Blowers, Sonic Soot Blower

Application : Soot Blowing

Weight : 100-1000kg

Color : Silver

Condition : New

Driven Type : Mechanical

Warranty : 1year

Automation Grade : Fully Automatic

Country of Origin : India

...more

SONIC SOOT BLOWER FOR APH

35,000 - 110,000 Per Set

Sonic Soot blower is based on the principle of kinetic activation of the dust particles, using sound waves generated by a sound generator, operated by compressed air. a microprocessor-based programmer controls the complete operation of system. Sonic Soot blower is based on the principle of kinetic activation of the dust particles. The sound generator sent out powerful sound signals, of low frequency & high intensity, at suitable intervals, inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces. These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas. It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter. It applicable at Package Boilers, Water tube boilers, Waste heat recovery boiler, Super heaters, Economisers, Air Heaters, Gas Heat Exchanger, Bag houses, Electrostatic Precipitators, fans, Soils, Hoppers & Ductwork.Benefits One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Type : Soot Blowers,Sonic Soot Blower

Application : Soot Blowing

Weight : 100-1000kg

Color : Silver

Condition : New

Warranty : 1year

Country of Origin : India

Automation Grade : Automatic,Fully Automatic

...more

Sonic Soot Blower

40,000 - 120,000 Per Piece

Benefits : One time installation Best to control pollution Increased equipment service life Lower operating cost Low maintenance Effective cleaning Fully automatic operation Continuous cleaning Reduced the frequency of Boiler maintenance

Type : Sonic

Certification : CE Certified

Application : Industrial

Color : Grey

Voltage : 220V

Driven Type : Electric

Warranty : 1 Year

...more

Rectus Steam Trap

2,000 - 10,000 Per Pieces

Main function of any steam trap is to trap the steam and drain out the condensate water. In industry there are many types of steam trap like thermodynamic steam trap, float steam trap, inverted bucket steam trap & Venturi Orifice steam trap. There is huge difference in working principle of Venturi float Steam trap and other regular steam trap. There are mainly two problems in other regular mechanical operating steam traps are as under so preventive testing and maintenance required frequently. 1. Steam traps fail in open condition ( Occur mostly in TD steam trap): 2. Steam traps fail in closed condition so backing up condensate causing (Occur mostly in Float and Bucket steam trap): Note : In float steam trap there are permanent steam loss through SLR. All these problems are eliminated in Venturi Float Steam trap due to there are Ventury and float two orifice are in working. In Venturi float Steam Trap there are two orifice working to remove condensate from Steam System. One is Venturi orifice which is design as per client condensate load and pressure at inlet of trap and second is float valve orifice. Ventury orifice nozzle is sized to handle 100% of the condensate load produced by a particular application. Normally ventury orifice is in working condition. Float orifice is in closed condition. Some time at starting of process and low pressure condition there are float orifice is open and remove excess water from system. So this Venturi Float steam trap can cope up efficiently the condensate load at start up, normal running and pick load condition. DESIGN FEATURES • Two orifice mechanism control condensate flow at all levels • Tailor made Venturi orifice design control condensate flow automatically • Continuous discharge of condensate • Efficient condensate discharges due to 0.001 kg/cm2 differential pressure against 0.1 kg/cm2 of other make trap • Built in air vent for quick start up • Wear resistance construction as SG iron cover and base & stainless steel internals part Advantages and Benefits • No SLR so no steam wastage due to miss setting of SLR • Moving parts is rarely work and so no required maintenance for long time • Permanently eliminate the need of steam trap survey and repairing cost • CO2 emissions are reduced through reducing steam consumption and boiler fuel usage. • Environment Friendly • Save water and water treatment chemicals • Permanent steam savings about 10 to 45% • Increased heat transfer typically 10% • Unaffected by thermal shock or water hammer so increasing plant life.

Size : 1/2inch,1inch,2inch

Type : Steam Traps

Brand Name : IEPL

Material : Carbon Steel

Application : Water Fitting

Color : Black

Feature : Corrosion Proof,Good Quality

Condition : New

Pressure : High,Low,Medium

Country of Origin : India

End Connection : Screwed

...more

Pressure Powered Pumping Packaged Unit

100,000 - 2,800,000 Per piece

1 Piece (MOQ)

There are Power Pressure Pump Package Unit or Condensate recovery unit or power pressure pump use for transfer steam condensate from plant to boiler feed water tank with help of motive steam or air. Working of Principal Condensate recovery pump or Power pressure pump: There are two stage of pump working 1) Filling Mode: Condensate from process will be collected in pump receiver tank due to gravity it will open Check valve and start filling pumping tank. By this time motive inlet is closed and vent outlet is open so there is no back pressure. This will lead level low to high. 2) Pumping Mode: As the level reaches set high level vent valve shut off and open the motive steam or air valve. This will allow motive steam or air in tank and push the water level in downward direction. By this time Delivery Check Valve will be open and inlet check valve shut off. When low level reached automatically repeat the cycle. I.e. shut off the motive valve and open the exhaust. In Comman mechanical pump there are mechanical assembly which are very complicated and lot of moving part. It cost is to high. Also SS float puncture with time due to constant expansion and contraction due to temperature variation. While In our system "APPLIED FOR PATENT" We avoid complication of the operation. We remove ss float which are puncher after some time. We use special material float which can operate for almost life time. So there are no wear and tear will be there so it's almost maintenance free. Our system will be working for almost it's life cycle. Features 1. Pump Total Material are SS 304 Material so life is long life. 2. Float material is Special Materials so it will not punctured. 3. No moving part assured zero maintenance. 4. Suitable for high temp. Application. No cavitations problem 5. Can be operated on compressed Air. 6. Various sizes for different capacities.(max. cap.6,000 kg/hr)

Country of Origin : India

Type : Pumping Unit

Weight : 100-1000kg, 1000-2000kg

Condition : Good

Automatic Grade : Automatic

Pressure : High Pressure

Warranty : 1year

Material : SS And MS

...more

Oxygen Controller

150,000 - 2,500,000 Per Sets

Industrial environment can get a little tricky and Oxygen Analyzer and Controller ensures that the gas levels are within the safe margin. It measures the gas level injected in food and pharmaceutical industries. It comes with Zirconium Oxygen sensor that senses the presence of oxygen with high efficiency. The response time of one second is calibrated automatically. We comply with the best industrial standards to ensure comprehensive service. Features: Accurate readings and stats Reliable and high quality parts Enhances safety in industrial readings Technical Specification: Zirconium Oxygen Sensor Made in UK 4 to 20 mA RS 232 Probe Length 220 mm / 400 mm 0.1 to 25% O 2 , Auto Calibration response time 1 sec 100C to 400C. Oxygen Controller with Display. Features: No Moving Parts No need for Temperature Stabilization Functional Testing and Calibration in Ambient Air. Long Life. Potential Applications: Furnace/Heating boiler Control Industrial Process Control Combustion Systems Compost systems Environmental Control Benefits: Up to 3.5% fuel Savings & up to 20% Power Saving in ID Fan power. Reduced Co 2 emissions. Optimization of fuel to air ratio Improved Boiler Efficiency.

Application : Flue Gas Analysis

Color : Off White

Feature : Accuracy,Digital Display,Easy To Carry

Condition : New

Driven Type : Electric

Country of Origin : India

Detected gas : O2

Automation Grade : Automatic

Brand Name : IEPL

...more

Oxygen Analyzer & Controller

202,000 Per Piece

Industrial environment can get a little tricky and Oxygen Analyzer and Controller ensures that the gas levels are within the safe margin. It measures the gas level injected in food and pharmaceutical industries. It comes with Zirconium Oxygen sensor that senses the presence of oxygen with high efficiency. The response time of one second is calibrated automatically. We comply with the best industrial standards to ensure comprehensive service. Features: Accurate readings and stats Reliable and high quality parts Enhances safety in industrial readings Technical Specification: Zirconium Oxygen Sensor Made in UK 4 to 20 mA RS 232 Probe Length 220 mm / 400 mm 0.1 to 25% O 2 , Auto Calibration response time 1 sec 100C to 400C. Oxygen Controller with Display. Features: No Moving Parts No need for Temperature Stabilization Functional Testing and Calibration in Ambient Air. Long Life. Potential Applications: Furnace/Heating boiler Control Industrial Process Control Combustion Systems Compost systems Environmental Control Benefits: Up to 3.5% fuel Savings & up to 20% Power Saving in ID Fan power. Reduced Co 2 emissions. Optimization of fuel to air ratio Improved Boiler Efficiency.

Type : Automatic

Certification : CE Certified

Application : Industrial

Driven Type : Electric

Accuracy : 100%

...more

Ms Mechanical Condensate Pump

70,000 - 220,000 Per Set

1 Piece (MOQ)

presently in some of industry, condensate is collected in the collection tank and there after it is being pumped by conventional electrically operated centrifugal pumps. in this process 15-20° c temperature reduce as it is stored in collection tank. while in boiler condensate pump condensate water is pumped as soon as it is filled. so there is not significant temperature drop. electrical pump require frequent maintenance, while boiler condensate pump have only float type moving part which is fit and forgot type. electrical pump faces the problem of dry running due to high vapour pressure while boiler condensate pump will never have these problems. electrical pump faces the cavitations and pitting problems while boiler condensate pump will never have this problem. features 1. boiler condensate pump having no moving part assured zero maintenance. 2. boiler condensate pump utilise of flash steam. 3. boiler condensate pump suitable for high temp. application. no cavitations problem 4. in condensate recovery pump less steam consumption at low pressure. 5. boiler condensate pump can be operated on compressed air. 6. boiler condensate pump automatic venting of air & non - condensable gases 7. easy monitoring of boiler condensate pump operation can be checked in sight glass. 8. boiler condensate pump of various sizes for different capacities.( max. cap.12,000 kg/hr ) 9. boiler condensate pump skid mounted so easy to install. application : boiler condensate pump use for tracing line, radiator, cyclinder, dryer, heat exchanger, vessels, jacketing, oven, heating tank condensate recovery pump use for industries like pharma, textile, automobile, petro chemical, paper mill, sugar mill, processing unit, chemical etc…

Type : CONDENSATE RECOVERY PUMP

Certification : TEST

Color : Blue

Feature : Cost Effective,REDUCE FUEL COST

Condition : New

Warranty : 1 Year

Country of Origin : India

Automation Grade : Automatic

...more

MS CONDENSATE RECOVERY PUMP

75,000 - 200,000 Per Set

1 Piece (MOQ)

Presently in some of industry, condensate is collected in the collection tank and there after it is being pumped by conventional electrically operated centrifugal pumps. In this process 15-20° C temperature reduce as it is stored in collection tank. While in Boiler condensate pump condensate water is pumped as soon as it is filled. So there is not significant temperature drop. Electrical pump require frequent maintenance, while Boiler condensate pump have only float type moving part which is fit and forgot type. Electrical pump faces the problem of dry running due to high vapour pressure while Boiler condensate pump will never have these problems. Electrical pump faces the cavitations and pitting problems while Boiler condensate pump will never have this problem. Features 1. Boiler condensate pump having no moving part assured zero maintenance. 2. Boiler condensate pump utilise of flash steam. 3. Boiler condensate pump Suitable for high temp. Application. No cavitations problem 4. In Condensate recovery pump less steam consumption at low pressure. 5. Boiler condensate pump Can be operated on compressed Air. 6. Boiler condensate pump Automatic venting of Air & Non - Condensable gases 7. Easy monitoring of Boiler condensate pump operation can be checked in sight glass. 8. Boiler condensate pump of Various sizes for different capacities.( max. cap.12,000 kg/hr ) 9. Boiler condensate pump skid Mounted so easy to install. Application : Boiler condensate pump use for tracing line, radiator, cyclinder, dryer, heat exchanger, vessels, jacketing, Oven, heating tank Condensate recovery pump use for Industries like Pharma, Textile, Automobile, Petro chemical, Paper mill, Sugar mill, Processing unit, chemical etc…

Application : Steam Boiler Plants

Color : Blue

Power : Hydraulic

Country of Origin : India

...more

Iepl Power Pressure Pump

100,000 - 200,000 Per piece

1 Set (MOQ)

MECHANICAL CONDENASATE PUMPThere are Condensate recovery unit or power pressure pump use for transfer steamcondensate from plant to boiler feed water tank with help of motive steam or air.Working of Principal Condensate recovery pump or Power pressure pump: There are two stage of pump working 1) Filling Mode: Condensate from process will be collected in pump receiver tank due togravity it will open Check valve and start filling pumping tank. By this time motive inletis closed and vent outlet is open so there is no back pressure. This will lead level low tohigh.2) Pumping Mode: As the level reaches set high level vent valve shut off and open the motive steam or air valve. This will allow motive steam or air in tank and push the water level in downward direction. By this time Delivery Check Valve will be open and inlet check valve shut off.When low level reached automatically repeat the cycle. I.e. shut off the motive valveand open the exhaust.In Comman mechanical pump there are mechanical assembly which are very complicated and lot of moving part. It cost is to high. Also SS float puncture with time due to constant expansion and contraction due to temperature variation.While In our system "APPLIED FOR PATENT" We avoid complication of the operation. We remove ss float which are puncher after some time. We use special material float which can operate for almost life time. So there are no wear and tear will be there so it's almost maintenance free. Our system will be working for almost it's life cycle.Features1. Pump Total Material are SS 304 Material so life is long life.2. Float material is Special Materials so it will not punctured.3. No moving part assured zero maintenance.4. Suitable for high temp. Application. No cavitations problem5. Can be operated on compressed Air.6. Various sizes for different capacities.(max. cap.12,000 kg/hr)

Country of Origin : India

Type : Condensate Recovery Pump

Application : Steam Boiler Plants

Color : Blue

Power : Pneumatic

...more

Iepl Condensate Recovery System

100,000 - 200,000 Per piece

Mechanical condenasate pumpthere are condensate recovery unit or power pressure pump use for transfer steamcondensate from plant to boiler feed water tank with help of motive steam or air.working of principal condensate recovery pump or power pressure pump: there are two stage of pump working 1) filling mode: condensate from process will be collected in pump receiver tank due togravity it will open check valve and start filling pumping tank. By this time motive inletis closed and vent outlet is open so there is no back pressure. This will lead level low tohigh.2) pumping mode: as the level reaches set high level vent valve shut off and open the motive steam or air valve. This will allow motive steam or air in tank and push the water level in downward direction. By this time delivery check valve will be open and inlet check valve shut off.when low level reached automatically repeat the cycle. I.e. Shut off the motive valveand open the exhaust.in comman mechanical pump there are mechanical assembly which are very complicated and lot of moving part. It cost is to high. Also ss float puncture with time due to constant expansion and contraction due to temperature variation.while in our system "applied for patent" we avoid complication of the operation. We remove ss float which are puncher after some time. We use special material float which can operate for almost life time. So there are no wear and tear will be there so it's almost maintenance free. Our system will be working for almost it's life cycle.features1. Pump total material are ss 304 material so life is long life.2. Float material is special materials so it will not punctured.3. No moving part assured zero maintenance.4. Suitable for high temp. Application. No cavitations problem5. Can be operated on compressed air.6. Various sizes for different capacities.(max. Cap.12,000 kg/hr)

Type : Condensate Recovery Pump

Application : To Move condensate Water to feed water tank

Color : Blue

Fuel : No Need

Power : Pneumatic

Structure : Condensate Pump

Country of Origin : India

Type : Power Pressured Pump

...more

Iepl Condensate Recovery Pump

100,000 - 200,000 Per piece

MECHANICAL CONDENASATE PUMPThere are Condensate recovery unit or power pressure pump use for transfer steamcondensate from plant to boiler feed water tank with help of motive steam or air.Working of Principal Condensate recovery pump or Power pressure pump: There are two stage of pump working 1) Filling Mode: Condensate from process will be collected in pump receiver tank due togravity it will open Check valve and start filling pumping tank. By this time motive inletis closed and vent outlet is open so there is no back pressure. This will lead level low tohigh.2) Pumping Mode: As the level reaches set high level vent valve shut off and open the motive steam or air valve. This will allow motive steam or air in tank and push the water level in downward direction. By this time Delivery Check Valve will be open and inlet check valve shut off.When low level reached automatically repeat the cycle. I.e. shut off the motive valveand open the exhaust.In Comman mechanical pump there are mechanical assembly which are very complicated and lot of moving part. It cost is to high. Also SS float puncture with time due to constant expansion and contraction due to temperature variation.While In our system "APPLIED FOR PATENT" We avoid complication of the operation. We remove ss float which are puncher after some time. We use special material float which can operate for almost life time. So there are no wear and tear will be there so it's almost maintenance free. Our system will be working for almost it's life cycle.Features1. Pump Total Material are SS 304 Material so life is long life.2. Float material is Special Materials so it will not punctured.3. No moving part assured zero maintenance.4. Suitable for high temp. Application. No cavitations problem5. Can be operated on compressed Air.6. Various sizes for different capacities.(max. cap.12,000 kg/hr)

Type : Condensate Recovery Pump

Application : To Move condensate Water to feed water tank

Color : Blue

Fuel : No Need

Power : Pneumatic

Country of Origin : India

...more

Iepl Condensate Pump

100,000 - 200,000 Per piece

1 Set (MOQ)

MECHANICAL CONDENASATE PUMPThere are Condensate recovery unit or power pressure pump use for transfer steamcondensate from plant to boiler feed water tank with help of motive steam or air.Working of Principal Condensate recovery pump or Power pressure pump: There are two stage of pump working 1) Filling Mode: Condensate from process will be collected in pump receiver tank due togravity it will open Check valve and start filling pumping tank. By this time motive inletis closed and vent outlet is open so there is no back pressure. This will lead level low tohigh.2) Pumping Mode: As the level reaches set high level vent valve shut off and open the motive steam or air valve. This will allow motive steam or air in tank and push the water level in downward direction. By this time Delivery Check Valve will be open and inlet check valve shut off.When low level reached automatically repeat the cycle. I.e. shut off the motive valveand open the exhaust.In Comman mechanical pump there are mechanical assembly which are very complicated and lot of moving part. It cost is to high. Also SS float puncture with time due to constant expansion and contraction due to temperature variation.While In our system "APPLIED FOR PATENT" We avoid complication of the operation. We remove ss float which are puncher after some time. We use special material float which can operate for almost life time. So there are no wear and tear will be there so it's almost maintenance free. Our system will be working for almost it's life cycle.Features1. Pump Total Material are SS 304 Material so life is long life.2. Float material is Special Materials so it will not punctured.3. No moving part assured zero maintenance.4. Suitable for high temp. Application. No cavitations problem5. Can be operated on compressed Air.6. Various sizes for different capacities.(max. cap.12,000 kg/hr)

Type : Condensate Removal Pumps

Color : Blue

Fuel : No Need

Power : Pneumatic

Country of Origin : India

Type : Mechanical

...more

Thermal Energy Audit

1 Piece (MOQ)

Energy is often the single largest controllable cost in manufacturing. Proper management of energy has a direct positive impact on a company’s bottom line. Energy audit is the first step in knowing the potential energy savings. It identifies area where the energy is being wasted by taking measurements at the key energy consumption points and the systematic study. It determines existing level of energy usage and recommends possible measures that would result in energy savings.

...more

energy audit

1 Piece (MOQ)

Energy is often the single largest controllable cost in manufacturing. Proper management of energy has a direct positive impact on a company’s bottom line. Energy audit is the first step in knowing the potential energy savings. It identifies area where the energy is being wasted by taking measurements at the key energy consumption points and the systematic study. It determines existing level of energy usage and recommends possible measures that would result in energy savings.

...moreBe first to Rate

Rate ThisOpening Hours

Innovative Enerpro Private Limited is a celebrated name in the market of Ahmedabad. We are involved in manufacturing, exporting, and supplying the finest quality steam trap, condensate recovery pump, sonic soot blower, and oxygen analyzer & controller. The steam trap that we offer is manufactured using the best quality materials and tools. These steam traps are largely appreciated for their fine quality and durability. The condensate recovery pump provided by us is widely known for its smooth functioning. Our Sonic soot blower is widely known for its high-quality and long service life. Moreover, our specialization in providing oxygen analyzer & controller has made us more popular in the industry.

Situated in Ahmedabad (Gujarat, India), Innovative Enerpro Private Limited is operating in the industry since 2010. Under the headship of Mr. Piyush Kakadiya (Director), we have evolved as a phenomenal name in the industry.

Our Team

A squad of meticulous and adroit delivery experts, supervisors, technicians, managers, engineers, packaging experts, and many more is there for us to handle all our company operations. The professionals that we have hired in our team have contributed equally to the company’s growth in the past times.

Why Choose Us?

Working in the industry for more than a decade, we have been able to earn a decent clientele in Ahmedabad and other cities of Gujarat as well. In addition to this, we are also instrumental in making absolute transparency throughout all the transactions with the clients.