Wovensack Flexo Press

Features 3 Drive System Control Panel Operator interface touch screen at rewinder side. Print unit Control panel Shaftless Rewinder/Unwinder Unit Electronic Edge Guide System Pneumatic Infeed/Outfeed system Registration Control Horizontal/Cercumference Doctor Blade with ceramic Anilox Roller Motorized Web video inspection System Motorized ink pump system Electronic Line Shaft Technology Auto Tension Control with load cell at unwinder stand

...more

Web Tension Control Unit

Direct web tension control by using three drive control system consists of Load cell based closed loop vector controlled individual AC frequency drives for (I) Unwind station (II) Main drive (III) Rewind station. Unwind : Auto web tension control system by using vector controlled AC drive & motor Main Drive : Vector controlled AC drive & motor Rewind : Auto web tension control system by using vector controlled AC drive & motor

...more

Waterwash Flexo Plate Machine

@Flexo Photopolymer Plate Making Machine For Waterwash flexo Plate Making Equipment (Model : @C-A2SSF / @C-A3SSF / @C-A4SSF / @C-2430 / @C-3040) Plates suitable : Label, film, paper, corrugated board, paper carton,  bag, Tetra pak etc. Exposure + Washout + Drying +Treatment (Light finishing) in complete set @C-A2SSF All stainless steel. Exposing+drying+washout+treatment. With water circulation & filtration system. Simple operation, best plate result Features of Exposure unit : Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicato Features of Washout unit : High temperature water washout With water circulation system Special arrangements of brush With residue filtration system Features of Drying unit : Drying drawer with uniform heat distribution Temperature adjustable by a precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Features of Treatment unit : Chemical free operation, simple, easy and save Digital timer for light finishing control Philips UVC high intensity lamps equipped With powerful air exhausting for big size models

...more

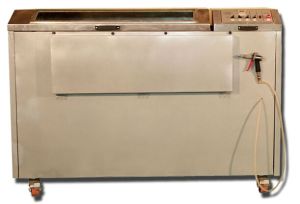

Washout unit

Features of Washout unit : Rotary washout to save operating room Operation-watching window. Solvent tank equipped with level indicator Before-finish washout exhaustion design Indicator for brush roller distance Wrap-a-round washout gets better results Both solvent spray and steep type design Brush distance adjustable for any thickness lates.(Inside) Roller rotation and brush horizontal movements

...more

Varnish Flexo Photopolymer

varnish Special Features @flexo Photopolymer Plate making machineFor Varnish Plate Making Equipment(Model : @2430 ET + WD / @3040 ET + WD / @4050 ET + WD) Plates suitable : TORAY / Trelief, TOYOBO/ Printight, OHKA / Miraclon, BASF / Nyloprint etc. For printing : Letterpress,dry offset, tag, label, computer form, tampo, pad and vanish coating etc. Exposure + Washout + Drying 3 in one, all stainless steel made. ( Except @A4 ) Features of Exposure unit : Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Washout unit : Flat washout unit 3 in 1 for easy access Special bristle good for all kind plates wash Automatic control of temperature precisely Excellent result for 200 LPI 1% reproduction Features of Drying unit : Drying drawer with uniform heat distribution Temperature adjustable by a precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Model @2430 for 24X30 inch(610x762 mm) @3040 for 30x40 inch(762x1016 mm) @4050 for 40x50 inch(1016x1270mm)

...more

Thermal Image Setter

Thermal Image Setter OYO Instruments' thermal image setter technology offers clear, compact, environmentally friendly solutions to artwork production, enabling you to eliminate outsourcing of large-format films and bring production control in-house. OYO's unique, chemistry-free, dry-imaging Thermo Impression ® film requires absolutely no fixers, developers, inks or toners while providing UV densities that exceed industry standards. The Liberator GMAX Series is built using OYO's latest innovative and proprietary technologies. Closed Loop Registration (CLR) control gives you accurate registration overlay and Multi-Level Pulsing (MLP) delivers consistent dot quality. OYO's Liberator GMAX ThermoImpression Systems help you meet bigger demands more efficiently, while producing full-size film up to 54 inches wide. Liberator GMAX ThermoImpression Systems include a Harlequin ScriptWorks® RIP Management System. This forward thinking, trouble-free, fully featured RIP is PostScript® compatible and is fully compliant with PostScript LanguageLevel 3 specifications, the latest version of the PostScript page description language (PDL). Each system configuration also includes Harlequin's own patented FM screening technique, Harlequin Dispersed ScreeningT Lite (HDS Lite). The bottom line: accurate registration, high performance and affordable price. Thermal Image Setter : 18?, 28?, 36?, 42? and 54" media widths 600 or 1200 dpi resolution Up to 133 lpi (line screen) Produce dark films with density between 4.0 and 5.0 using SPx or XP film Outputs film positives and negatives Great for flexo, offset and screen printers Imaging speeds up to 6 inches per minute Closed Loop Registration (CLR) control Latest Harlequin RIP with media saving Chemistry, darkroom and processor-free NO inks, toners, cameras or disposal costs Automatic media cutter In-house production control Low maintenance Accurate registration and repeatability (plus or minus 0.01% measured at a length of 60 inches) Exceptionally Affordable New Prepress Solution for the Textile and Screen Printing Industries 14.25? media width 600 x 600 dpi resolution Imaging of up to 6 inches per minutes Closed Loop Registration (CLR) control Multi-Level Pulsing (MLP) Optional Harlequin® RIP Requires NO inks, toners, cameras or disposal costa Automatic Media Cutter USB interface In-house production control Simple, hands-off operation Low maintenance The TechstylerT Wide-Format Thermal Imagesetter gives screen printers an exceptionally affordable, wide-format film output solution enabling the efficient printing of full body graphics right to the edge while producing full-size 600 x 600 dpi film up to 14? wide. OYO's Closed Loop Registration (CLR) control ensures tight registration and delivers both accuracy and consistency. The new TECHStyler is capable of producing professional, on-demand, film separations right in your own shop - without a darkroom, without a processor and without chemicals. OYE Instruments' thermal imagesetter technology offers clear, compact, environmentally friendly solutions to artwork production, enabling you to eliminate outsourcing of large-format films and bring production-control in-house.unique, chemistry-free, dry-imaging thermolmpression® film requires absolutely no fixers, developers, inks or toners while providing UV densities that exceed industry standards. The TECHStyler Thermoimpression System includes either a Harlequin or Wasatch software RIP Solution.Both RIP pachages offer Postscipt® compatibility, while also supporting PDF, TIFF and EPS file formats. Each system configuration also includes traditional PostScript halftoning, as well as stochastic screening algorithms. The bottom line : wider edge to edge printability, better day to day performance, improved resolution and registration, less waste, lower costs and affordable price. Specifications : Printhead Configuration : Single- substrate, thick film linear array Printing Method : Direct thermal technology Resolution : 600 x 600 dpi Media Drive : Stepper motor Paper Type : ThermolmpressionT Polyester Film Paper Length : 200 Foot roll Film Type : ThermolmpressionT Polyester Film Film Length : 200 foot roll Optical Density (Film) : 4.0 typical (UV) Registration Accuracy : +-0.01% or +-0.00 in/20 in or 0.05 mm/500 mm Interface : USB Operating Requirements : Voltage : 115 or 220 VAC (Auto-switch) Frequency : 50-60 Hz Power Usage : 50 Watts idle mode, 600 Watts plot/print mode Temperature : Operating: 60° to 80° F(15° to 27° C), Storage/Shipping Range: 14° to 158° F (-10° to 70° C), Humidity: 5 to 95% non-condensing Media Temperature : Operating : 60° to 80° F(15° to 27° C), Storage/Shipping Range : 14° to 86° F (-10° to 30° C), Humidity : 5 to 95% non-condensing Imagesetter Model Selection Chart : Model : TECHStyler Media Width : 14.25 in (361.95 mm) Plot Width : 14.08 in (357.6 mm) Plot Rate : 6.14 in/min (155.96 mm/min) Height : 10.9 in (27.7 cm) Width : 23.5 in (59.69 cm) Depth : 20.5 in (52.1 cm) Net Weight : 72 lbs (32.7 kg)

...more

stainless steel drying washout Machine

All stainless steel. Exposing+drying+washout. 3 in one design very compack. Simple operation, best plate result. Whole system includes exposing unit, washout unit, drying unit.

...more

solvent distillation unit

Solvent Distillation Unit @flexo 30L - RHB / @flexo 60L-RHB / @flexo 80L-RHB / @flexo 100L-RHB / @flexo 200L-RHBSpecial Features Solvent recovery unit for photopolymer flexo plates A. General description: This is designed for recovery of flexographic photopolymer plate solvent washout chemical and any environmental green chemical with specialties of distilling and cooling, can be connected with in-line processor and any plate washout machine directly. With cold air circulation and drain out of residue for high speed recovery. Super recovering rate in the shortest time, is an ideal and high efficient recovery unit for flexographer. B. Technical information: Recovery volume : 60 / 80 liters Power consume: 220V 4.65KWDiathermic oil : 23 KG Machine dimension: Main body: 1100x 780x1200 mmRecovery rate: 85%Recovery time : 3 ~ 4 hours

...more

Regular Line Flexography Machine

Models : @2430 / @3040 / @4050 Plate Making Size : @ 2430 = 24 x 30 inch (610 x 762 mm) @ 3040 = 30 x 40 inch (762 x 1016 mm) @ 4050 = 40 x 50 inch (1016 x 1270 mm) Features of Exposure unit : Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Washout unit : Flat washout unit 3 in 1 for easy access Special bristle good for all kind plates wash Automatic control of temperature precisely Excellent result for 200 LPI 1% reproduction Exposure + Treatment Unit (ET) Washout + Drying Unit (WD) Features of Drying unit : Drying Drawer with uniform heat Distribution Temp. Adjustable by a precise Controller Unique Air Circulation and Exhaustion Design Over Heat sensor for Safety & Protection Anti-Track Treatment Flexo : Chemical Free Operation, Simple Easy & Safe Digital Timer for light Finishing time Control Equiping With Philips High Intensity Lamps With Powerfull Air Exhausting for Bad Odour

...more

Printign Station

Printign Station High Quality Ceramic Anilox Roller With double Close doctor chamber system able to high quality printing with Motorized Ink Pump Ceramic Anilox Rollers: Robotic plasma coated and laser engraved with improved cell structure ceramic anilox rollers with quick change over Chamber Doctor Blade: Specially designed chamber doctor blade group, ensure straight profile of the blade resulting in lesser chamber pressure, better print quality & longer anilox roll life. Motorized Web Video Inspection System Motorized web video inspection system consists of high quality CCD color camera, Industrial PC & Monitor (facilitates sequential inspection of the lateral and entire print repeat of the web).

...more

Photopolymer Plate Making Machine

Special Features@flexo Photopolymer Plate making machine for Water Wash Flexo Plate(Model : @C-A2SSF / @C-A3SSF / @C-A4SSF / @C-2430 / @C-3040) (Model : @C-A2SSF / @C-A3SSF / @C-A4SSF / @C-2430 / @C-3040) Plates suitable: TOYOBO / Cosmolight, TORAY / Toreflex etcFor printing: Label, film, paper, corrugated board, paper carton, knitting bag, Tetra pak etc.Exposure + Washout + Drying +Treatment (Light finishing) in complete set Features of Washout unit High temperature water washout With water circulation system Special arrangements of brush With residue filtration system Features of Exposure unit Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Drying unit Drying drawer with uniform heat distribution Temperature adjustable by a precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Features of Treatment unit Chemical free operation, simple, easy and save Digital timer for light finishing control Philips UVC high intensity lamps equipped With powerful air exhausting for big size models

...more

Liquid Polymer Equipments

@flexoBag is a brand new development of flexographic plate making system for corrugated & paper printing industryThis innovative creation is experienced from both of conventional liquid photopolymer and solvent plate for 30 years. @flexoBag is a faster exposure, with fine reproduction details, water wash-out, easy and rapid operation system. For a 4mm plate for corrugated board printing exposure time is only 5 min, wide latitude, fine details, no bubbles, tolerance within +/- 0.03mm, good for all kids of flexo printing. Available size up to 42 x 60 inch (110 x 160cm), larger size equipment is available under your request. @flexoBag Plus drying and anti-tack treatment whole process for a 4 mm plate is less than 20 minutes. Your existing plate making machine is also good enough for this system, only a new double side exposure unit is required. Most important is that total plate making cost is only 50% of a solvent-wash photopolymer plate. @flexoBag Water wash-out is the best advantage of this system, do not have to use solvent means less drying time, quick ready, saving cost from production and environmental green. Water washout time is only 3 min. for a 4mm plate. Sealing Unit (BS) : With instant and constant sealing results for the image size you required, to avoid various stock for different gauges and dimensions. Filling Unit (BF) : With high pressure air from your own air-compressor to fill in the photo-polymer resin to the bag with no bubble for immediate plate making. Recovering Unit (BR) : With air-knife to clear off and collect the unhardened photopolymer in order for reuse, by this will also increase 10-20% of your production. Models : @2436 (for plate size up to 24 x 36 inches = 60 x 90 cm) @4260 (for plate size up to 42 x 60 inches = 110 x 160 cm) Exposure Unit : Double-size exposure + anti-tack treatment unit (GT) with high intensity lamps good for fine dot reproduction. With powerful air exhausting during atit-tack treatment. Washout + Drying Unit : Flat water washout with recirculation & filtration + Drying unit (WD) with built-in water heating, circulating and filtration system with sticky mounting during washout - no double side tape required.

...more

letterpress plates

@A4-LT / @A3-LT For Letterpress Plates Exposure + Washout + Drying Units 3 in 1 Exposure unit Features Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Washout unit Flat washout unit 2 in 1 for easy access Special bristle good for all kind plates wash Automatic control of temperature precisely Excellent result for 200 LPI 1% reproduction Features of Drying unit Drying drawer with uniform heat distribution Temperature adjustable by precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Solvent Washout Plates Special Features : @flexo Photopolymer Plate making machine For Flexography Plate Making Equipment Model : (@A2SSF / @A3SSF / @A4SSF) (@2430 / @3040 / @4050) Plates suitable : DuPont / Cyrel,Ohkaflex, Flex-Light, Asahi / AFP, BASF / Nyloflex, JET.. For printing : Label, film, paper, corrugated board, paper carton, knitting bag, Tetra pak etc. Exposure / Washout / Drying /Treatment (Light finishing) in complete functions. Exposure unit Features Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Washout unit Flat washout unit 2 in 1 for easy access Special bristle good for all kind plates wash Automatic control of temperature precisely Excellent result for 200 LPI 1% reproduction Features of Drying unit Drying drawer with uniform heat distribution Temperature adjustable by precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Features of Treatment unit Chemical free operation, simple, easy and save Digital timer for light finishing control Philips UVC high intensity lamps equipped With powerful air exhausting for big size models Models @A4 FL ( 21 x 30 cm ) @A3 FL ( 30 x 42cm ) @A3SSF ( 30 x 42cm ) @A2SSF ( 42 x 60 cm ) @2430 ( 24 x 30 in ) @3040 ( 30 x 40 in ) @4050 ( 40 x 50 in ) @A4 FL/@A3FL For Label/Card/Pad/Stamp @A4 / @A3LT-for letterpress @A4 / @A3LR-for liquid resin @A4 / @A3FL-for flexography @A4 / @A3FB-for @FlexoBag ( New modern design CAD/CNC cut body with outdoor A/C treatment / paint plus stainless steel tank all unit rust free. Warranty for ever free for first year.High intensity original Philips lamp good for 200LPI 1% dot reproduction )

...more

In-feed Out-feed System Draw unit

In-feed & Out-feed System (Draw unit) The system mainly composed of matt chromium plated steel roller, and rubber covered nip roller with pneumatically adjustable pressure.

...more

flexography plate making

Flexography Plate Making Solvent Washout Plates Special Features @flexo Photopolymer Plate making machine For Flexography Plate Making Equipment Model : EDT(Exposure + Dryer + Treatment ) RW (Rotary washout) @1600 :- @1600 EDT+RW ( 1.1 x 1.6 m ) @2001 :- @2001 EDT+RW ( 1.1 x 2.0 m ) @2002 :- @2002 EDT+RW ( 1.3 x 2.0 m ) Plates suitable : DuPont / Cyrel,Ohkaflex, Flex-Light, Asahi / AFP, BASF / Nyloflex, JET.. For printing : Label, film, paper, corrugated board, paper carton, knitting bag, Tetra pak etc. Exposure / Washout / Drying /Treatment (Light finishing) in complete functions. Features of Exposure unit : Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Drying unit : Drying drawer with uniform heat distributions Temperature adjustable by a precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Features of Treatment unit : Chemical free operation, simple, easy and save Digital timer for light finishing control Philips UVC high intensity lamps equipped With powerful air exhausting for big size models Features of Exposure unit : Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Washout unit : Flat washout unit 3 in 1 for easy access Special bristle good for all kind plates wash Automatic control of temperature precisely Excellent result for 200 LPI 1% reproduction Features of Drying unit : Drying drawer with uniform heat distribution Temperature adjustable by a precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Features of Treatment unit : Chemical free operation, simple, easy and save Digital timer for light finishing control Philips UVC high intensity lamps equipped With powerful air exhausting for big size models

...more

Flexographic Printing Machine

CI Servo Driven ELS Type Flexographic Printing Machine CENTRAL DRUM FLEXO PRESS "Mantrine Flex" C.I Flexo Printing Press Specially design for high quality short & medium run colour printing jobs. It is applicable to both plastic films and paper

...more

Flexo Printing Press Machine

Technical 3 Drive System Control Panel Operator interface touch screen at rewinder side. Print unit Control panel Shaftless Rewinder/Unwinder Unit Electronic Edge Guide System Pneumatic Infeed/Outfeed system Registration Control Horizontal/Cercumference Doctor Blade with ceramic Anilox Roller Motorized Web video inspection System Motorized ink pump system Electronic Line Shaft Technology Auto Tension Control with load cell at unwinder stand

...more

Flexo Photopolymer letterpress

letterpress Special Features @flexo Photopolymer Plate making machinefor Letterpress Plate Making Equipment(Model : @A2SS / @A3SS / @A4) Plates suitable : TORAY / Trelief, TOYOBO/ Printight, OHKA / Miraclon, BASF / Nyloprint etc. For printing : Letterpress,dry offset, tag, label, computer form, tampo, pad and vanish coating etc. Exposure + Washout + Drying 3 in one, all stainless steel made. ( Except @A4 ) Features of Exposure unit : Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Washout unit : Flat washout unit 3 in 1 for easy access Special bristle good for all kind plates wash Automatic control of temperature precisely Excellent result for 200 LPI 1% reproduction Features of Drying unit : Drying drawer with uniform heat distribution Temperature adjustable by a precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Models : @A4 @A3SS @A2SS Exposure + Drying + Washout , 3 in 1. Plates suitable : Toyobo printight, Tokyo ohka miraclon, Toray torelief, Basf nyloprint etc. For printing : Letterpress, dry offset tag, lable, computer form, tampo, pad printing and vanishing

...more

EDLF EURO FLEX MACHINE

Features Combined Exposure, dryer Light finishing units. Exposure with cooled bed Lamp temperature control Two drying sections with two drawers each. Exposure units with automatic Pneumatic lid Safety Switch Cooled bed with intergrated chiller Light intergrator for automatic UV variation compensation

...more

Drying Exhaust System

Drying & Exhaust System Drying Chamber: Mainly consists of AC frequency drive controlled heavy-duty blower with connection duct and dampers to balance fresh and recycling air. The optimized air flow, minimizes heat consumption and avoid solvent retention in the printed substrates. Central Exhaust System: AC frequency drive controlled solvent extraction system to exhaust contaminated air from all the print stations through central duct.

...more

CENTRAL DRUM FLEXO PRESS

CI Servo Driven ELS Type Flexographic Printing Machine "Mantrine Flex" C.I Flexo Printing Press Specially design for high quality short & medium run colour printing jobs. It is applicable to both plastic films and paper

...more

Automatic Stamp Making Machine

MODELS : @A4-FL / @A3-FL Plate Making : For Photopolymer Stamp Exposure + Washout + Drying + Treatment Units 4 in 1 Features of Exposure unit Instant light up Philips high intensity lamps Unique digital timers for back/main exposure Excellent lamps cooling / exhausting system Quick vacuum drawdown pump with indicator Features of Washout unit Flat washout unit 2 in 1 for easy access Special bristle good for all kind plates wash Automatic control of temperature precisely Excellent result for 200 LPI 1% reproduction Features of Drying unit : Drying drawer with uniform heat distribution Temperature adjustable by a precise controller Unique air circulation and exhaustion design Over heat sensor for safety and protection Features of Treatment unit Chemical free operation, simple, easy and save Digital timer for light finishing control Philips UVC high intensity lamps equipped With powerful air exhausting for big size models PLATE MAKING TIPS : Flexo plate making process Back ExposureExpose UV light from the back side of Photopolymer to make floor first. Contact of Negative filmPeel-off protective film. Contact the emulsion side of negative onto the surface of Photopolymer Main Exposure ExposeUV light through the negative. Wash-outRemove the negative, and process the plate in Flate Photopolymer washout unit. DryingAfter wiping off the surface moisture by sponge roll, dry in a hot air dryer © 60° Post-exposureExpose UVA light again to complete photo-curing. After-treatmentExpose UVC Germicide lamp as light finishing in order to remove surface stickiness. Letterpress plate making process Contact of Negative film Peel-off protective film and place negative film on undeveloped plate. Use negative having optical density of not less than 3.0 ExposureExpose plate, through negative film, to UVA light. Determine the correct exposure time using a 21 step grey scale. Follow the Photopolymer plate supplier . Wash-outRemove negative film & Wash exposed plate with water. Time depends on plate thickness. Follow the Plate Supplier TIPS. Rinse the plate with fresh water. DryingDry the plate in a hot-air dryer after taking-off the surface water with a sponge roll. Drying time is different due to the type of plate. Follow the TIPS FOR Photopolymer Plate' Post exposureExpose the developed plate to UVA light again to get stability. Post exposure time should be the same or longer than the main exposure time.

...more

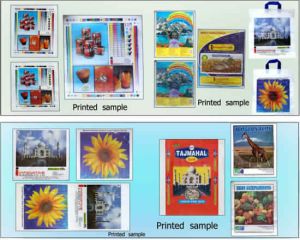

8 COLOR HIGH SPEED FLEXOPRINTING MACHINE

CHARACTERISTICS OF FLEXOGRAPHIC PRINTING MACHINE This Machine is suitable to printing of rolling paper. Packing paper glass paper, P.P., P.E. and Polysterene HDPE etc. Robust construction minimizes space occupied and enhances productivity. Using hydraulic system to set the printing plates, it is easy and accurate. There will be no defects when starting and stopping the machine. The built-in impression counter can be presented and stops the machine automatically when the desired quality of prints is acquired, and starts again on reset. The throw-off or on action of printing cylinder is hydraulically operated. The interlocking mechanism keeps the inking rolls running to avoid drying of ink on such rolls, accomplishing the throw-off of printing cylinder. Using a hot-air dryer and a cold-air fan simultaneously, it makes the production speedier. The dryer and fan will shut down automatically when the machine stops, it makes this machine more safe. The built-in stops the machine automatically. The machine consisting of: UNWIND UNIT PRINTING UNIT MAIN DRIVE INFEED & OUTFEED UNIT DRYING UNIT REGESTRATION UNIT INKING UNIT REWIND UNIT SIDE FRAME CONSTRUCTION DUPLEX SYSTEM

...more

Geared Motor

Be first to Rate

Rate ThisOpening Hours