Wing Fender

They are used in small jetties and fishing harbours.

...more

Wedge Bolts

Wedge Bolt Assemblies are used for the fitment of Fenders to the existing Dock or Jetty wall “DIPTI” Wedge Bolt Assemblies are used to install new fenders to an existing dock or jetty wall. “DIPTI” Wedge Bolts are inserted in pre-drilled holes and fitted with an expansion mechanism and bonded by epoxy resin to ensure a fail proof system for the installation of the fender on to the wharfs. One Wedge Bolt Assembly contains a single fender fixing bolt, a single sleeve with hardened taper pin and a single loose washer matching the fender type. “DIPTI” Wedge Bolt Assemblies are available in both mild steel (MS) galvanized and stainless steel (SS) as per specifications.

...more

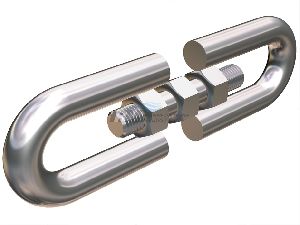

U Hooks

IRM manufactures ‘U Hooks’ required for fixing of chains for the fender systems. “DIPTI” U Hooks are available both in Mild Steel (MS) and Stainless Steel (SS) in different grades. Hooks are required for fixing of chains for Fenders or Fendering systems in new wharfs, jetties or structures. These hooks can also be used as an anchor for mooring rings.

...more

Turn Buckle Assembly

Turn Buckle is used in the fender chain to eliminate any slag in the chain for optimum tension. “DIPTI” Turn Buckle is used in the fender chain to eliminate any slag in the chain for optimum tension. They are also used to adjust chain length.

...more

tug boat fenders

Tug Boat Fenders are made of high abrasion resistant rubber with good resilience properties. “DIPTI” Tug Boat Fenders are available in TF-A type, TF-B type, TF-C type, TF-D type. “DIPTI” TF-A series Tug Boat Fenders are available in different sizes & shapes. These Fenders are made of high abrasion resistance rubber with good resilience properties for required application. “DIPTI” Tug Boat Fenders are available in TF-A type, TF-B type, TF-C type, TF-D type. These Fenders are easy to install and dismantle with user friendly fixtures, tools & tackle with a chain running through the center of the fender and straps or chains to fit into the grooves around the outside diameter of the fender. They are very popular with small port craft owners and tug owners. These Fenders are compression moulded in high pressure thermic fluid heated moulds and do have excellent sea water resistance. These Fenders are also having excellent resistance to ozone ageing and UV rays, which enhances the fender life under severe working conditions. “DIPTI” TF series Tug Boat Fenders are available in wide range from 100 mm outer diameter to 800 mm outer diameter and various lengths as per customer requirement.

...more

Tug Boat Fender

“DIPTI” TF-A series Tug Boat Fenders are available in different sizes & shapes. These Fenders are made of high abrasion resistance rubber with good resilience properties for required application. “DIPTI” Tug Boat Fenders are available in TF-A type, TF-B type, TF-C type, TF-D type.These Fenders are easy to install and dismantle with user friendly fixtures, tools & tackle with a chain running through the center of the fender and straps or chains to fit into the grooves around the outside diameter of the fender. They are very popular with small port craft owners and tug owners. These Fenders are compression moulded in high pressure thermic fluid heated moulds and do have excellent sea water resistance. These Fenders are also having excellent resistance to ozone ageing and UV rays, which enhances the fender life under severe working conditions.

...more

Strip Fenders

These Strip Fenders are generally used for fishing harbors, small ferry wharfs or small boat jetties. “DIPTI” DSF series Strip Fenders are generally used for fishing harbors, small ferry wharfs or small boat jetties, where the reaction force and energy absorption required is very low. These fenders are fitted to avoid damage to the expensive ferries or small boats and the structure itself. At times, these fenders are used for edge protection to avoid damage to boats/ferries. The fenders are easy to install and maintenance free. “DIPTI” DSF series Strip Fenders are made of high abrasion resistant Poly Urethane (PU) Rubber with steel insert and offer excellent resistance to sea water, ozone ageing and U V rays.

...more

steel buoys

IRM offers a wide range of buoys required in different applications and has got an excellent experience of manufacturing rubber coated steel buoys. Recently, IRM has become exclusive sales partner for world class PE buoys of Mobilis, France in India.

...more

SS Ladders

IRM manufacture custom built ladder for different marine applications. “DIPTI” Ladders are available both in stainless steel & moulded rubber as per specific requirement. Unique dual application fender ladders are also available, which can be used as a fender for small boats as well as ladder.

...more

Square Fenders

Square fenders are used on tugs, Ocean going Vessels, and Boats. These Fenders are also used for extensive applications on small jetties and fishing harbours. “DIPTI” DSQ-A series square fenders are used on tugs, vessels, boats etc. “Dipti” DSQ fenders are also used extensively in applications for small jetties and fishery harbors. Being compression moulded fenders, they are easy to install and replace and possess excellent sea water resistance, resistance to ozone ageing and ultra violet rays.

...more

shock pads

Shock Pads are extensively used for transportation of top decks /heavy structures by sea. They are distinctively designed to absorb heavy loads due to the waves during the voyage. “DIPTI” Shock Pads are extensively used for transportation of top decks /heavy structures by sea. They are distinctively designed to absorb heavy loads due to the waves during the voyage. These Shock Pads are very robust in construction and can accommodate very high loads with resilience to keep the deck / structure balanced. “DIPTI” Shock Pads can also be designed and manufactured as per customer’s requirements for different load applications.

...more

Shock Absorbers

Shock Absorber Series is specially designed for offshore platforms manufactured with a combination of steel and high modulus Rubber to absorb loads from multiple-directions. “DIPTI” SA series Shock Absorbers are specially designed for offshore platforms manufactured with a combination of steel and high modulus Rubber to absorb loads from multi-directions. The precision made concentric pipes when bonded together with rubber by a high pressure compression moulding process under controlled heating cooling- cycle, results in to a versatile energy absorption Element for Offshore Structures. “DIPTI” Shock Absorbers can absorb energy both in compression and torsion. It is having extremely good resistance to both axial load and bending. The high tensile rubber compound ensures good mechanical strength and excellent resilience. They are suitable in the marine environment and perform well in extreme climatic conditions. Special compound design offers excellent resistance to ozone ageing, ultra violet rays and sea water. Generally employed in combination with Eccentric Rubber Ring Steel fabricated Contact Post to absorb berthing energy at very high tidal variations at Platform. It absorbs and dissipates energy in every conceivable fashion and prevents damages to the structure. A unique Dock Entry Protection System made of 2 Shock Absorbers is also available, which protects Structures while moving Vessel is approaching to dock wall / entrance channel or Vessel coming for dry docking. The design of custom made Dock Entry Protection System can be provided on specific request. “DIPTI” SA series Shock Absorbers are available in 6 different models.

...more

SHEAR FENDERS

They are generally used in offshore installations. “DIPTI” Shear fenders have got excellent mechanical properties and sea water resistance rendering it virtually maintenance free. “DIPTI” DSQ series Shear Fenders are used to take berthing loads of Barge Bumpers / Boat landing structures axially and at the same time to absorb berthing energy laterally. They are generally used in offshore installations. These Fenders can also deflect more than 100% in Shear and absorb energy of lateral impact. “DIPTI” Shear fenders have got excellent mechanical properties and sea water resistance rendering it virtually maintenance free. It is easy to install and has got excellent load bearing capacity in axial compression too. “DIPTI” DSQ series Shear Fenders are available in four different models as shown here. Custom made Shear Fender can also be manufactured as per client’s requirements.

...more

stainless steel ladders

IRM manufacture custom built ladder for different marine applications. “DIPTI” Ladders are available both in stainless steel & moulded rubber as per specific requirement. Unique dual application fender ladders are also available, which can be used as a fender for small boats as well as ladder.

...more

Rotating Rubber Rings

Rotating Rubber Rings are used for protecting the contact posts in offshore applications. “DIPTI” DRR series Rotating Rubber Rings are the part of Barge Bumpers, which absorbs and dissipates berthing energy while rotating on to the Contact Post of Barge Bumpers. Its rotating movement reduces Shear force to be exerted by rubbing of Barges / Boats while berthing. They find extensive application in different configuration & Barge Bumper Assemblies. “DIPTI” Rotating Rubber Rings are versatile and can be used for different functions & specifications depending upon exact duty and working conditions. Our “DIPTI” DRR series Rotating Rubber Rings are available in 3 different models as shown here. These rings can also be supplied from high abrasive resistant polyurethane rubber.

...more

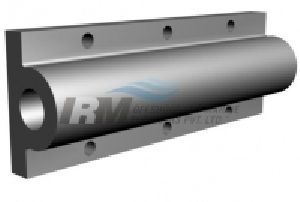

Roller Fenders

These Roller Fenders are more resistant to wear and tear, by the virtue of its capability to rotate in the direction of the vessels and move inside of housing in the direction of impact because of the special spring type design. “DIPTI” DR series Roller Fenders are the right choice to protect your structures while a vessel is approaching an entrance channel or coming for dry docking. These fenders are quite robust and can absorb large impacts while guiding the floating vessels / barges without damaging the structure. These fenders are more resistant to wear and tear, by the virtue of its capability to rotate in the direction of the vessels and move inside of housing in the direction of impact because of the special spring type design. These fenders can be installed vertically keeping in mind the rolling and pitching of vessels during loading and unloading of cargo. In case of this modified version, since the Roller is capable of horizontal movement, it can absorb the impact more smoothly compared to the fixed type roller fenders. “DIPTI” DR series Roller Fenders are manufactured using special technology for a uniform deflection of the rollers at its circumference and a smooth movement (rotation) in the direction of the force, thus ensuring a safe passage of the vessels without damaging the structures. The superior moulding technology employed in our high pressure thermic fluid heated hydraulic presses ensures a long life with trouble free performance. “DIPTI” DR series Roller Fenders are perfectly assembled in high tensile steel fabricated housing coated with high build epoxy paint and a suitable lubrication system to ensure trouble free operations. If required, services can be provided for supervising the installation of the roller fenders. All roller fenders come with complete details of all parts/components as well as a Periodic Maintenance and Service Manual which enables the end users to get maximum service life.

...more

resin anchor bolts

Resin Anchor Bolt Assemblies are used both in new structures and as replacements in old berths. One Resin Anchor Bolt assembly includes a fender fixing stud, nut, chemical resin capsule and a washer as per fender type. “DIPTI” Resin Anchor Bolt Assemblies are used both in new structures and as replacements in old berths. They are encapsulated in very high strength epoxy mortar. One Resin Anchor Bolt assembly includes a fender fixing stud, nut, chemical resin capsule and a washer as per fender type. “DIPTI” Resin Anchor Assemblies are available in both Mild Steel (MS) galvanized and \ Stainless Steel (SS) as per specifications.

...more

quick release hooks

Mampaey Offshore Industries B.V. is a leading supplier of Mooring, Berthing and Towing Systems, with Safety and Reliability as a shared value. The company is based in the Netherlands and founded in 1904. The buildup of experience resulted in hooks that define today’s industry standards. Mampaey Offshore Industries is ISO 9001 quality approved. Mampaey’s mooring and berthing product family is integrated in the iMoor® system. This modular system provides flexibility in selecting Mampaey components to form any desired iMoor® configuration. The easy to use iMoor® application software organizes the control centrally. Mampaey Offshore Industries is global market leader in the design, engineering, manufacturing & commissioning of integrated towing, mooring and berthing systems. Track record of innovative standards Mampaey, established in 1904, has a track record of maritime innovations that have become new standards in towing and mooring. All of them are still in use by customers world wide. Proven quality All Mampaey products are designed and manufactured to safely withstand the toughest mechanical and environmental conditions. Longer lifespan and low maintenance Mampaey’s products are manufactured of materials meeting the highest standards which therefore guarantee low maintenance and a minimum amount of spares needed.

...more

Pneumatic Fenders

Manufactured as per ISO 17357 with 0.5 kg/cm² and 0.8 kg/cm² internal pressure, these Fenders are extensively used for ship to ship transfers at mid sea, as well as vessel to berth at dock/jetty. “DIPTI” DPN series Pneumatic Fenders are manufactured as per ISO 17357 with 0.5 kg/cm² and 0.8 kg/cm² internal pressure (other internal pressures are available on request). These Fenders are extensively used for ship to ship transfers at mid sea, double banking operations as well as vessel to berth transfers at dock/jetty. These Fenders offer excellent energy absorption characteristics and do have a Linear load deflection characteristic. The special property of Pneumatic Fenders makes it suitable for Liquid cargo Vessels and Defense Vessels with very sensitive equipment. These Fenders offer excellent energy absorption characteristic and do have a Linear load deflection characteristic. They are very easy to install, remove and handle for various applications. These Fenders are generally equipped with chain nets and tyres or with wire rope nets, end rings, Towing Rings and Swivel Joints with suitable D-Shackles at both ends for better life. Sling type Fenders are also available on specific request. These Fenders offer excellent resistance to shear force, inclined compression and are highly reliable. The carefully crafted high abrasion resistant external layer prevents atmospheric ageing and nylon tyre cord layers ensure high mechanical strength under heavy compression. Internal rubber layers ensure a positive seal to maintain the desired internal pressure. The latest moulding technology, a combination of heat, pressure and accurate process parameters makes our pneumatic fenders extremely reliable and ensure a trouble free long life. These Fenders are also supplied in grey colour for non-staining / Naval applications. “Dipti” DPN series Pneumatic Fenders are available in wide range from 500mm Diameter to 4500mm Diameter and 1000mm Length to 12000mm Length as per customer’s requirements.

Length : 12000mm

...more

Marine Fender

These fenders are manufactured by compression moulding in single piece with steel insert plates encapsulated in the legs to provide a firm fitment with the jetty.These fenders are robust and have a good shear resistance. The unique rubber compound developed for these Fenders has excellent U.V. resistance, resistance to ozone ageing, resistance to sea water and extreme climate conditions from a very low ambient temperature to very high temperatures. They can easily be installed vertically, horizontally or inclined, thereby covering and protecting the jetty more efficiently. Arch fenders can be manufactured in various sizes depending on the requirement. Arch fenders can be fitted with a UHMW pad or with a frontal frame to reduce friction and hull pressure.

...more

Leg Mating Units

Leg Mating Unit (LMU) is specially designed for the smooth installation of the top deck on the jacket legs. They generally take lateral misalignment jerks and vertical loads and position the top deck easily on the Jacket. They can be provided in both Top Deck and Jackets as per the requirement. These units are subjected to cyclic test, load deformation test and extreme load bearing capacity test in view of its critical function. “DIPTI” Leg Mating Unit (LMU) is specially designed for the smooth installation of the top deck on the jacket legs. They generally take lateral misalignment jerks and vertical loads and position the top deck easily on the Jacket. The deck is lowered on these mating units and they smoothly transfer these load to the structure without jerks and impact loading. “DIPTI” Leg Mating Unit is a combination of horizontal elastomers and vertical elastomers assembled in metal fabricated cans. These elastomeric units with structural support show a very good resilience in actual load transfer conditions. “DIPTI” Leg Mating Unit can be provided in both Top Deck and Jackets as per the requirement. These units are subjected to cyclic load test, load deformation test and extreme load bearing capacity test in view of its critical function. The elastomers of our Leg Mating Units are capable of performing without creeping under high load as they are made from special grade elastomeric compound to achieve desired test results. “DIPTI” Leg Mating Units are available in different designs. More details can be provided on specific request. Custom made Leg Mating Units are designed and manufactured as per client’s requirements. IRM possesses in house facility to design, manufacture & test the LMU’s including evaluation of design with FEA and further manufacturing and testing of the LMU under stringent quality check.

...more

Ladder Fenders

Ladder Fender units are used to avoid damage to expensive ferries or small boats and structures. “DIPTI” DLF series Ladder Fender units are generally used for small ferry wharfs or small boat jetties. These fenders are used to avoid damage to expensive ferries or small boats and structures. These fenders are made of high abrasion resistant rubber with steel inserts that offer excellent resistance to sea water, ozone ageing and U V rays.

...more

Key Hole Fenders

Key Hole Fenders are the most versatile bow & stern fenders used on Tug Boats, small Port Craft and Ferries. These Fenders are made of high abrasion resistant rubber with good resilience properties. “DIPTI” KH-A series Key Hole Fenders are the most versatile bow & stern fenders used on Tug Boats, small Port Craft and Ferries. They offer maximum protection to the Tugs and Ferries with the typical profile and load absorbing capabilities. These are very easy to install and replace, thus making the maintenance hassle free. Being made of high abrasion resistant rubber these Fenders display good resilience properties. DIPTI KH-A series Key Hole type Fenders are available in 200mm to 300mm height and length as per customer requirement.

...more

Jacket Leg Rub Strips

Jacket Leg Rub Strips are custom built Arch Fenders for protecting the offshore platform. They work effectively in extreme climatic conditions. “DIPTI” DA series Jacket Leg Rub Strips are custom built Arch Fenders for protecting the offshore platform transportation and launching. They absorb considerable shock and protect the Offshore Jacket Legs from the Barges and Vessels while transporting / launching. They have a long life and reliability and offer excellent resistance to sea water. They work effectively even in extreme climatic conditions without any shortfall in performance. Our “DIPTI” DA series Jacket Leg Rub Strips are available in 300mm height in different lengths as shown here. Custom made Jacket Leg Rub Strips can also be designed and manufactured as per requirement.

...moreBe first to Rate

Rate ThisOpening Hours