Y Type Strainer

Y-Type Strainers are typically used in application where the amount of solids to be removed is small, and where frequent clean – out is not required.They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions. “Y” Strainer mechanically removing solids from flowing liquids, Air, Steam or gases by means of a perforated or wire mesh straining element. OPERATING PRINCIPLES – Y-Strainer has the advantage of being able to be installed in either a horizontal or vertical position. The screening element or “leg” must be on the “downside” of the strainer body so that entrapped solids can be properly collected and held for disposal. A blow down plug on the drain port will allow clean-out without removal of the screen, and without interrupting the process flow. FEATURES & OPTIONS:- Highly durable that makes it a part of various industrial applications The affordable rates content our clients to the utmost level Can be availed in customized specifications Negligible maintenance Easy cleaning or replacing the element. Compact size and Low weight Low Pressure drop across the filter. Low Installation and maintenance. With Drain Arrangement on request Adequate strength of element and housing Interchangeability of component with another of same type. Wire mesh up to 5 Micron Design & Testing International Standard MATERIAL OF CONSTRUCTION:- Body & Cover Cast Iron to ASTM A 126 Class BIS 210 GR. FG 200 / 220 / 260Cast Carbon Steel to ASTM A 216 GR. WCBStainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3MCarbon Steel to IS 2062 (Fabricated Type)S.S. 304 / 316 / 304L / 316L (Fabricated Type)Others on request Mesh (Element) S.S. 304S.S. 316S.S. 304LS.S. 316LBrass DESIGN & TESTING INTERNATIONAL STANDARD: Design Std. : Mfg. Standard Pressure Testing : Mfg. Standard Face To Face : Mfg. Standard Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392 Pressure Rating : 125#, 150# Size Range : 40mm (1½”) To 300mm (12”)

...more

wafer swing check valve

Wafer swing Check Valves type combines a simple but robust construction with reliability. They are specially designed and developed for applications where a low pressure loss is essential. J.D. Wafer Type Swing Check Valve has short face to face dimensions and low weight allows a simple space saving installation between the companion flanges. The valves are suitable to mounting between weld neck or slip on plate type companion flanges of different standards. The short face to face dimensions and the low weight guarantee a simple and space saving installation between the bolts of the connecting flange.

...more

Wafer Check Valve

PURPOSE – JD check valves are ideally suitable for vertical and horizontal application. A range of Check Valves (Non-Return Valves) suitable for oil, gas, water, refining, power and chemical applications where the prevention of flow reversal is mandatory. DESIGN & OPERATING PRINCIPLES :- DESIGN –JD Wafer Type Check Valve has short face-to-face dimensions and low weight allows a simple space saving installation between the companion flanges. The valves are suitable to mounting between weld neck or slip on type companion flanges of different standards.They are specially developed for applications where a low-pressure loss is essential. OPERATING PRINCIPLE-Opening and closing of the valve will take place at an extremely low-pressure difference over the valve disc. The eccentric disc shaft combination with the disc seat guarantees a positive shut off returning media. Wafer check valves are becoming the preferred type of check valve for most applications, due to their compact design and relatively low cost. MATERIAL OF CONSTRUCTION: Cast Iron : IS 210 Gr FG 200 Cast Carbon Steel : ASTM A 216 Gr WCB Cast Stainless Steel : ASTM A 351 Gr CF 8/CF 8M Seat : Nitrile, Neoprene, PTFE End : Wafer Type Pressure Rating : ASA 125#, 150# Size Range : 50 mm to 300 mm DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : API 6D Pressure Testing : API 598 Face To Face : ANSI B 16.10 Mounting Between : ANSI B 16.5 / BS 10 Table / DIN / IS 6392

...more

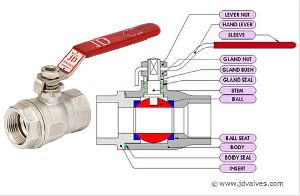

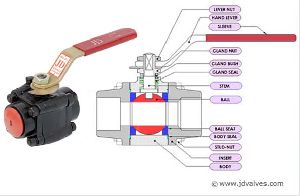

two way ball valves

J D Controls mfg. High performance Ball Valve as per international design and standard to get 100% Client Satisfaction and repeat order with total interchangeability, superior quality, workmanship & service. These Ball Valves come in Single Piece (1/2 to 4) / Two Piece (1 to 8) as well as in Three Piece Design (1/2 to 12) to suit various critical, non-critical applications and pressure rating up to 1500 class in both full bore & regular (reduce) bore design. J D P.T.F.E. seated Ball Valves gives Zero Leakage, Tight Shut-Off and Low Torque with easy smooth operation at temperature ranging from -20° C. to +220° C. Electro-Polished, Buff Finish & Ultra clean valve also provided for Food & Pharmaceutical Industries on request. SALIENT FEATURES: High Performance Ball Valve Longer Life Positive Shut off Quick in Action No Lubrication Compact Design Low Pressure Drop Visual Open / Close Indication Simplicity SPECIAL OPTIONS: Extended Bonnet Type Partial / Full Jacketed Ball Valve Handle Locking Arrangement P.T.F.E. (PFA / FEP) Lined Ball Valve Flush Bottom Design Ball Valve Multiport Ball Valve (Three Way / Four Way) Polypropylene Material Ball Valve Tri-Clover End Ball Valve Pneumatic Rotary Actuator Operated Ball Valve Tailor Made Ball Valve MATERIAL OF CONSTRUCTION: Cast Iron : IS 210 Gr FG 200Cast Carbon Steel : ASTM A 216 Gr WCBCast Stainless Steel : ASTM A 351 Gr CF 8/CF 8MSeat, M. O. C. Of Seat : Nitrile, Neoprene, EPDM, Hyplon, PTFEEnd Connection : Screwed AS PER BSP/BSPT/NPTSocketweld : AS PER ANSI B 16.11Flanged : AS PER ANSI B 16.5Pressure Rating : ASA 125#, 150#, 800#Engineering Option : Gear Operated, Electrical Actuated, Pneumatic ActuatedSize Range : 6 mm to 150 mm DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 / API 6DPressure Testing : BS 6755 Part II / API 598 / API 6DFire Safe Testing : BS 6755 Part II API 607 / API 6FA /Face To Face : ANSI B 16.10Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392Butt Weld End : ANSI B 16.25Socket Weld End : ANSI B 16.11Screwed End : ANSI B 1.20.1(BSP/NPT)

...more

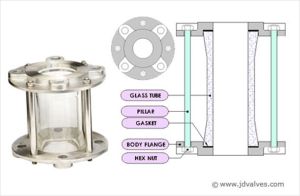

TUBULAR / FULL VIEW TYPE SIGHT GLASS

TUBULAR / FULL VIEW TYPE SIGHT GLASS [SIGHT FLOW INDICATOR] :- Sight Glass (Sight Flow indicators) is used for monitoring flow in pipelines for a wide range of applications. J. D. Controls manufacturing Sight Glass suitable for various rugged industrial applications. These Sight Flow Indicators are bi-directional type and easy to install in any orientation. Sight Glass (Sight Flow Indicators) provides a quick, reliable and economical way to verify the flow of liquids through industrial process pipe lines. J. D. Tubular Type Sight Glass available with different length of glass from 4 (100mm) to 8 (200mm) long. J. D. Sight Glass (Sight Flow Indicators) has been designed with outstanding quality and the feature you need to streamline your operations. Full view types Sight Glass (Sight Flow Indicators) are widely used for corrosive chemicals, acids and colored liquids. Sight Glass (Sight Flow Indicators) are generally used in processes, where spot required to detect presence of media, or to visual inspect color, clarity, turbidity, or other critical characteristics. Sight Glass can be installed vertically or horizontally in the middle of any kind of non transparent pipeline and are very convenient & easy to observe the flow from any direction. SALIENT FEATURES : Easy Maintenance Lower Cost Wide View Area to Inspect the Fluid Tempered Borosilicate glass standard Available in all most all M.O.C. Glass Length available from 100MM To 200MM Sizes Range from 15MM To 200MM Pressure Rating PN 6 Design & Testing As Per Mfg. Standard End Connections as per ANSI B 16.5/BS 10 Table/DIN/IS 6392 Std. MATERIAL OF CONSTRUCTION: Body Carbon Steel to IS 2062AISI 304 (Stainless Steel 304)AISI 316 (Stainless Steel 316)AISI 304L (Stainless Steel 304L)AISI 316L (Stainless Steel 316L) GasketP.T.F.E. (Teflon ) / CAF GlassTempered Borosilicate Glass FastenersCarbon SteelStainless Steel 304 / 316Stainless Steel 304L / 316L

...more

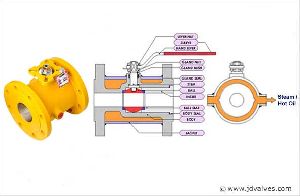

Trunnion Ball Valve

We manufacture High performance Ball Valve as per international design and standard to get 100% Client Satisfaction and repeat order with total interchangeability, superior quality, workmanship & service. These Ball Valves come in Single Piece (12 to 4) Two Piece (1 to 8) as well as in Three Piece Design (12 to 12) to suit various critical, non-critical applications and pressure rating up to 1500 class in both full bore & regular (reduce) bore design.

...more

Three Way Valve

Three Way Ball Valves

T PORT BALL VALVE – ALSO KNOWN AS A MIXING VALVE. As shown in fig – a valve member i.e Ball – has three ports. Different flow combinations are possible as shown in the fig It is easy to see that a T valve can connect any pair of ports, or all three, together, but the 45 degree position which might disconnect all three leaves no margin for error. T-Port valves can also direct flow between the centre and one of two side ports. The difference is that they have a third handle position that connects the centre to both side ports at the same time.JD Multiport 3 Way Ball valves utilize four seats to support the ball, and to provide positive shutoff at any closed port. Multiple Gland Packing Seal & Spring Washer gives zero leakage from gland portion SALIENT FEATURES: High Performance Ball Valve Longer Life Positive Shut off Quick in Action No Lubrication Compact Design Low Pressure Drop Simplicity DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 / API 6DPressure Testing : BS 6755 Part II / API 598 / API 6DFire Safe Testing : BS 6755 Part II API 607 / API 6FA /Face To Face : ANSI B 16.10Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392Butt Weld End : ANSI B 16.25Socket Weld End : ANSI B 16.11Screwed End : ANSI B 1.20.1(BSP/NPT) MATERIAL OF CONSTRUCTION: Body / End Connector Piece: Cast Iron to ASTM A 126 Class B IS 210 GR. FG 200 / 220 / 260Ductile Iron to ASTM A 536 Grade 65-45-12Cast Carbon Steel to ASTM A 216 GR. WCBStainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3MHast Alloy B / CASTM A 351 GR. CN 7M (Alloy 20)

Size : DN25/25mm/One Inch 1” To DN300/300mm/ Twenty Four Inch 12”

...more

TANK VALVE

Swing Check Valve

SWING CHECK VALVES :- PURPOSE:- JD check valves are ideally suitable for vertical and horizontal application. A range of Check Valves (Non-Return Valves) suitable for oil, gas, water, refining, power and chemical applications where the prevention of flow reversal is mandatory. DESIGN & OPERATING PRINCIPLE :- DESIGN – JD Check Valves are Bolted cover design up to 600# and above pressure seal design. It is designed for long service life and maintenance free operation. It has a full-flow area body and is equipped with a disc arm with dual precision pins for optimum disc connection and protection against damage due to vibration. OPERATING PRINCIPLE-A swing check valve consists of a flap or disc of the same diameter as the pipe bore, which hangs down in the flow path. With flow in the forwards direction, the pressure of the fluid forces the disc to hinge upwards, allowing flow through the valve. Reverse flow will cause the disc to shut against the seat and stop the fluid going back down the pipe. In the absence of flow, the weight of the flap is responsible for the closure of the valve; however, in some cases, closure may be assisted by the use of a weighted lever. SALIENT FEATURES : Body & Cover made from high quality casting with liberal sections. The castings are precision machined for high performance. Body Seat Ring & Disc machined to close Tolerances providing smooth action and accurate seating. Seat Ring Screwed in to the body are replaceable type. Seal welded type Seat Ring & Integral Seat cab also be offered on special request. Stellited Seat Ring & Disc also be offered on special request. In built wear life for long duration in service. SPECIAL OPTION:- Body Type: Single Thin Plate, Short Type Suitable For Horizontal and Vertical Mounting Shorter overall length, mounting requires minimum space. Low Pressure Drop Easy to Install Less Weight Size Range: 1” To 42” Pressure Rating: PN 10 / PN 16 Seat Leakage: Zero Leakage, Tight Shut Off Temperature Range: -250 To + 2000 C Material of Construction: Cast Iron : IS 210 Gr FG 200Cast Carbon Steel : ASTM A 216 Gr WCBCast Stainless Steel : ASTM A 351 Gr CF 8/CF 8MForged Carbon Steel : ASTM A 105Forged Stainless Steel : ASTM A 182 Gr F304 / F316Design Type : Swing Type Disc / Piston Lift Type DiscEnd Connection : Screwed AS PER BSP/BSPT/NPTSocketweld : AS PER ANSI B 16.11Flanged : AS PER ANSI B 16.5Pressure Rating :ASA125#,150#,300#,600#,800#,PN16&PN 40Engineering Option : Gear Operated, Electrical Actuated,Size Range : 15mm to 300 mm Design & Testing International Standard: Valve Design : API 6DPressure Testing : API 598Face To Face : ANSI B 16.10Flanged Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392Butt Weld End : ANSI B 16.25Socket Weld End :ANSI B 16.11Screwed End :ANSI B 1.20.1(BSP/NPT)

...more

slurry valves

PURPOSE:- Slurry valve is specially designed to throttle liquids which contains suspended solids, because of extreme abrasion encounter in slurry control services, materials such as hardened metal alloys or wear resistant rubbers are commonly utilized for these applications. OPERATION & CONSTRUCTION:– Aluminum Body / Cast Iron, Pinch Valves having Rubber sleeves are extra heavy with full covering flanges preventing corrosion on body and four reinforced pulling lugs for positive operation. The sleeve is internally completely reinforced. J.D. PINCH valves are having special lock nut device on wheel for standard tightening in closed position, minimizing extra permanent pressure on sleeve, extending the life of sleeve. Lock nut gives sleeve tightening setting. The sleeve is internally completely reinforced, which withstand against continuous operation. The sleeve is such designed that it will retain complete roundness In full open position giving full flow of pipe line. Valves are fullway-seatless & glandless, Heavy Duty replacable Elastomere sleeve. Four reinforced pulling lugs give positive & definite results in open & closed position, prevents sleeves from collapse even in vacuum full covered flanges protects from corossion effects. Can be drilled to DIN, Bs 10, Is or any standard. This valves incorporates all the modified designs based on our vast experience in the field. The valves are of complete sturdy construction to handle various abrassive & corrosive liquids. SALIENT FEATURES OF SLURRY VALVES: Straight Full Flow. No liquid hammering. Can withstand 8 kg/sqcm working pressure. Utility in vacuum upto moderate pressure. Perfect sealing even on Untrapped solids. Can handle most corrosive and abrassive materials. Built-in Flange Gaskets. Only replacable part – rubber sleeve !! Split casting ensure quick maintenance. Heavy Duty Graded Cast Iron / Aluminum Alloy. MATERIALS TO HANDLE : Chemicals, Alkaline Mixtures Acids, Slurries & Intermediates Liquid Foods Viscous Fluids Sludges Gramles Dry Suspension Powder Collectors Gases APPLICATION INDUSTRIES : Vacuum Sewage Plants Thermal P0wer Stations Watercontainingash Pharmaceuticals Ptcklings Textile Industry Mining & Cement Industry Acid & Chemicals Tankers Refineries Fertilizers

...more

Slimseal Butterfly Valve

Butterfly Valve have been developed with extensive application, design and manufacturing expertise. J. D. High Performance Slim-Seal, Concentric design Butterfly Valves are reliable, maintenance free shutoff with permanently gas-tight seal with an integrally moulded or replaceable elastomer body liner. J. D. Butterfly Body having two nos. flange locating holes for sizes up to 12 and from size 14 and above 04 nos. for easy alignment of valve during installation. Flange locating hole confirm to as per ANSI B 16.5 Class 125 & Class 150 BS 10 Table D, E, F PN 6, PN 10, PN 16 or other international standard. J. D. High performance b

...more

Pneumatic Valves

PNEUMATIC VALVES: J D Automation series ball valve accepts an actuator or gear box can be bolt directly on the mounting pad (as per ISO 5211) of the valve body. No. extra brackets/couplers are required. The bottom of the actuator is rest on the mounting pad of the valve. There are no external moving parts. The coupler/adapter is less subject to corrosion. An external bracket does not exist to create surfaces that may be untrue. This design alleviates a number of problems mentioned above. Automation Series Ball Valves known as Direct Mounting Pad Ball Valve, ISO Mounting Pad Ball Valve, ISO 5211 Direct Mounting Pad Ball Valve, Remote Operated Ball Valve, Pneumatic Operated Ball Valve, Actuator Operated Ball Valve, Fire Safe Ball Valve, Fire Safe Approved Ball Valve, API 607 Fire Safe Design Ball Valve, API 6D Ball Valve, Automatic Ball Valve, Electrical Operated Ball Valve ADVANTAGES OF JD DIRECT MOUNTING PAD VALVES FOR ACTUATOR & GEAR OPERATORS: International Standard : Featuring an ISO 5211 Mounting Pad for direct mounting of Actuators and Gear Box on valve.Strength of mount between : No brackets that can bend after installation. valve/actuatorSafety : No pinch pointsCompactness : Smaller/Shorter package takes up less space in pipe galley. Low Profile.Actuator/Valve Stem alignment : Shorter distance between valve/actuator allows closer tolerance to minimize torque.Modular: Simplicity : No confusion as to how bracket bolts to equipment’s or how to install adapter.Screwed End : ANSI B 1.20.1(BSP/NPT)Lighter Weight : Package no longer includes bracket and large adapter reduce weight.Direct valve stem/actuator connection :Less chance for hysterisis. One less connection with no adapter involved.Maintenance : Often no packing to adjust. Less corrosion in the valve stems Area from atmosphere.Long Life Performance : Its offer long life, smooth, easy performance without any preservingStandard Feature : Fire Safe Design, Antistatic Device & Blow-out Proof Stem. PNEUMATIC VALVE RANGE: ISO 5211 Pneumatic Valve, ISO 5211 Direct Mounting Pad Pneumatic Ball Valves, ISO Mounting Pad Pneumatic Ball Valve Manufacturer, Pneumatic Ball Valves Manufacturer, Exporter & Stockist

...more

Pipe Strainers

These types of strainers are named after their shape and normally used for course filtration. But with large filtration area can be used with fine mesh also. Body of Y strainer is normally of cast iron or cast steel in various grades with flanged and socket weld type end connection. Fabricated Y strainers are also available.

Specialities : Wire mesh up to 5 Micron, Design & Testing International Standard , Low Installation and maintenance. etc

...more

Pinch Valve

PURPOSE:- JD pinch valves are ideal solutions where shut-off and control applications involve abrasive or corrosive slurries, muddy sediment, silty liquid powders or coarse substances. The number of design variations is virtually unlimited as the modular structure of a JD valve enables the selection of any actuator, valve body construction and sleeve material to fit specific process conditions. OPERATING PRINCIPLES:- JD Pinch valve is simple. In the open position, the valve is at full bore with no flow restrictions thus making the valve an integral part of the pipeline. During closing, two pinch bars squeeze the sleeve shut on the centerline. The JD valves provide a 100% tight shut-off. MODULAR DESIGN OF THE PINCH VALVE JD modular pinch valve design has three main components: the sleeve, the body and the actuator (manual, pneumatic, and electric). The sleeve is the only part that is in contact with the process medium. The construction and materials of all three main components can be tailored to suit most process conditions. Self-cleaning JD CONTROLS valves provide 100% tight shut-off even if solids have built up on the sleeve wall. When compressed, any crystallized particles flake off the sleeve surface and are washed downstream. JD pinch valves are particularly suitable for the process industry for shut-off and control applications.JDC provides pinch valves with open, sealed and general line valve bodies. JD-PINCH VALVE OFFERS THE FOLLOWING BENEFITS: durability in demanding conditions Long service interval, low cost No blocks because of structure, reliability Can be tailored to the different needs TYPICAL USERS ARE: Mines and concentrator Wastewater processes Chemical industry The energy industry and power plants Pulp and paper mills Grain storage, loading, unloading (rubber sleeve for food) As a small manufacturer, we are agile and we can manufacture valves tailored to customer needs. The design, actuator, positioner, and sleeve are completely modifiable so you don´t have to make any compromises. The frame Can be galvanized and powder coated. Actuator: Pneumatic actuator controlled by magnetic valve or positioner from finish manufacturer Flange borings: Full size flange with flange borings, DIN or ANSI -standard. Frange borings have been galvanized and powder painted Sleeve: Is made of natural rubber with textile reinforcements. The sleeve is only part which is contact with the flowing material. Sleeve can be eaily changed. Press section: The positioner guides the press section of actuator into wanted position to control the flowing. Positioner/Magnetic valve: Controls the actuator. Magnetic valve opens or shut down the flowing. The place of positioner can be tailored. Opening stripes: Have been attached in to press section. This secures that the sleeve will open in every situations.

...more

Multiport Ball Valves

We offer a tremendous value in multi-port three and four way valves. Three Way Four Way Ball Valves a Specialty of J.D. Controls, a leading manufacturer and supplier of Ball Valve and Actuation. We have a wide range of Three Way & Four Way Ball Valve in Carbon Steel, Stainless Steel, Cast Iron and others metal on special request. Our Three Way Ball Valve & Four Way Ball Valve selection covers Full Port & Regular (Reduce) Port, Flanged End, Screwed End, Socket Weld, Butt Weld (Welded Neck) End & Tri-Clover End with Manual Hand Lever, Gear or Pneumatic Operation.

...more

jacketed valves

We offer a range of Fully Jacketed Ball Valves. The jacket covers the body from one flange to the other flange. The body is modified by adding oversize flanges. As example: 2" x 3" Jacketed Ball Valve has the nominal bore of 2" (DN 50) and the flange size is 3"(DN 80). It allows enough space for bolting clearance.

...more

jacketed ball valves

J. D. Controls offers a range of Fully Jacketed Ball Valves. The jacket covers the body from one flange to the other flange. The body is modified by adding oversize flanges. As example: 2″ x 3″ Jacketed Ball Valve has the nominal bore of 2″ (DN 50) and the flange size is 3″(DN 80). It allows enough space for bolting clearance. J. D. Controls offers a range of Fully Jacketed Ball Valves. The jacket covers the body from one flange to the other flange. The body is modified by adding oversize flanges. As example: 2″ x 3″ Jacketed Ball Valve has the nominal bore of 2″ (DN 50) and the flange size is 3″(DN 80). It allows enough space for bolting clearance. The Jackets assure consistent valve Heating or Cooling of the process media to prevent crystallization or seizing of flow media. The Jacketed Ball Valve (Heating Jacket Ball Valve) with very well design to help the high temperature steam or oil flow over the valve ball & body parts to keep the media liquid. This applies especially to media like bitumen and liquid sulfur. In addition, the efficient flow of media is ensured through the elimination of pockets. VALVE OPERATION: J D Ball Valves are generally supplied with manual hand lever or gear unit operated, depending on valve size. J D also offering Ball Valves with either Pneumatic or Electrical actuator operated for automation. Generally standard Jacketed Ball Valves are delivered in carbon steel and different types of stainless steel materials. Other special materials are available upon special request. J. D. Jacketed P.T.F.E. seated Ball Valves gives Zero Leakage, Tight Shut-Off and Low Torque with easy smooth operation at temperature ranging from -20° C. to +220° C. Electro-Polished, Buff Finish & Ultra clean valve also provided for Food & Pharmaceutical Industries on request. WIDE RANGE OF BODY SEAT, SEAL & PACKING J D Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) / PEEK to suit special requirement of client. SALIENT FEATURES: High Performance Ball Valve Longer Life Positive Shut off Quick in Action No Lubrication Compact Design Low Pressure Drop Simplicity Heating / Cooling Jackets Wide selection of Different Jacket Material DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 / API 6D Pressure Testing : BS 6755 Part II / API 598 / API 6D Face to Face : As Per ANSI B 16.10 Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392 Size Range : ½” x 1” To 6” x 8” MATERIAL OF CONSTRUCTION: Body / Insert Cast Carbon Steel to ASTM A 216 GR. WCB Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M Ball Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M Hast Alloy B / C ASTM A 351 GR. CN 7M (Alloy 20) Stem AISI 410 (S.S. 410 – 13% Cr. Steel) AISI 304 (S.S. 304) AISI 316 (S.S. 316) AISI 304L (S.S. 304L) AISI 316L (S.S. 316L) Hast Alloy B / C Alloy 20 Ball Seat / Gland Seal / Stem Seal P.T.F.E. – Virgin P.T.F.E. – Glass Filled P.T.F.E. – Carbon Filled Grafoil Jacket Material M.S. S.S. 304 S.S 316 S.S 304L S.S 316L

...more

Globe Valve

The globe valve is used for throttling flow control. Shut off is accomplished by moving the disc against the flow stream rather than across it as in the case with a gate valve. The globe valve is an excellent valve to use for on-off service, but is highly suited for frequent cycling and control of fluids anywhere in amount or volume between the open and closed positions. OPERATING PRINCIPLES :- This is a valve which entails multiple turns during hand operation. It is basically a linear action valve that has a piston or disk which seats on a single shaped seat or flat. They are mainly used to control the opening and closing of fluid flow.In the plumbing industry, globe valves are used to tightly seal when fully closed.This controls high pressure fluid streams in pipes. Fluid pressures vary from time to time while flowing. The valves have a stem that is vertically positioned in the body of fluid flow to control the changes in pressure. It has a globe-shaped body that is mainly separated by an inner baffle. It is the baffle which controls the flow and has two parts: ring shaped seat and the flat plug. we offer metal seatings so that the seating stress must not only high ,but also circumstantially uniform to achieve the desired degree of fluid tightness. SALIENT FEATURES : Body & Bonnet made from high quality casting with liberal sections. The castings are precision machined for high performance Rising Stem & Rising Hand Wheel Construction. Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature. Deep stuffing box is providing for tightness and maximum long packing life. Swinging Eye Bolts facilitate easy access to the stuffing box. Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position. Seat Ring Screwed in to the body (Replaceable Type) or integral type. Stellited Disc, Seat Ring & Back Seat can also be offered on special request. Higher Pressure & Higher Size Valves are provided with Thrust Bearings and also with Gear drive arrangements. SPECIAL OPTIONS : Angle & Y Type Design Available Parabolic, Regulating, Guided & Soft Seating Disc (Plug) available Extended Bonnet design for low temperature and cryogenic services. Gland Seal Design (Water Seal) With Lantern Ring Non-Rising Hand Wheel on special request Bolted Bonnet / Pressure Seal Bonnet Gear / Pneumatic Cylinder / Electrical Actuator Operated Locking Arrangement With NACE MR 0175 Tailor Made Valve MATERIAL OF CONSTRUCTION:- Cast Iron : IS 210 Gr FG 200Cast Carbon Steel : ASTM A 216 Gr WCBCast Stainless Steel : ASTM A 351 Gr CF 8/CF 8MForged Carbon Steel : ASTM A 105Forged Stainless Steel : ASTM A 182 Gr F304 / F316End Connection : Screwed AS PER BSP/BSPT/NPTSocketweld : AS PER ANSI B 16.11Flanged : AS PER ANSI B 16.5Pressure Rating : ASA 125#, 150#, 300#, 600#, 800#, PN 16 & PN 40Engineering Option : Gear Operated, Electrical Actuated,Size Range : 15mm to 300 mm DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 / API 6DPressure Testing : BS 6755-IFace To Face : ANSI B 16.10Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392Butt Weld End : ANSI B 16.25Socket Weld End : ANSI B 16.11Screwed End : ANSI B 1.20.1(BSP/NPT)

...more

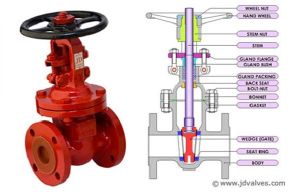

Gate Valve

A Stem [shaft] which moves perpendicular to the axis of flow of the working medium, there will be one gate or wedge in gate valve and it will control the fluid flow. Shape of gate or wedge of gate valve will be a type of flat circular plate or rectangular plate. Sometimes, gate or wedge is also termed as disc of gate valve. Gate Valve handle wheel when rotated in clockwise direction, steam and gate will move in downward direction across the fluid flow line and gate will be tightly located between the two seats. Hence there will not be any leakage of fluid through the valve once valve is closed completely. When handle wheel will be rotated in anti-clockwise direction, steam and gate will move in upward direction across the fluid flow line and valve will be opened from closed position and will permit the flow of fluid through the gate valve. Once gate valve is completely opened, it will permit no resistance or very little resistance to the flow of fluid. JD CONTROLS GATE VALVES:- JD. Controls Gate Valves are Outside Screw, Rising Stem, Bolted Bonnet Construction, threads are away from the line fluid and easy to lubricate. The body bonnet joint for all class of Gate Valve is in CircularRound/Rectangular Shape. In Gate Valve from 150# Rating body & bonnet joint have male-female type joint with a gasket. The Gate valve is also available in different types of Disc-Gate such as Double Disc Gate, Solid Gate, Flexible Gate, Parallel Slide Gate, Conduit Gate etc. to suit industrial various applications. Rising Spindle: -Outside Screw & Yoke (OS & Y) design keeps the stem threads outside the valve and is recommended where high temperatures, Corrosives, and solids in the line might damage the stem threads inside the valve. When Gate Valve will open, the stem extends above the hand wheel indicates the position of the gate. Valves Trims: –Trim refer to internal working parts of valves. In Gate Valves the Stem (Spindle), Seat Ring, Back Seat Bush, Gland Bush ARS trim parts. Valves Seat: – It can be Integral Seat with body Casting. Renewable: – Separate Seat Rings that screw into the valve body, which is called as Renewable Seats.JD Gate Valves are OS & Y Type, Rising Spindle, Bolted Bonnet design, threads are away from the line fluid and easy to lubricate. Gate Valve body ports are streamlined, permitting unobstructed flow, reduces turbulence, results in lower pressure drop and lower erosion. JD Gate Valves bonnet castings are of one – piece construction, where the yoke is integral with bonnet up to 6” size. Our manufacturing range also covers JACKETED GATE VALVE, Thermic Fluid Hot Oil Jacketed Gate Valve & Steam Jacketed Valve for sticky, viscous, molten sulphur, bitumen, asphalt application. JD An ISO 9001, ISO 14001 & OHSAS 18001 certified company Gate Valve Manufacturer, Alloy 20, Duplex Steel, Hastelloy, API 600, API6D, API 603 Standard Gate Valve Exporter, Supplier, Stockist, Importer. Rising Stem, Bolted Bonnet, Austenitic Stainless Steel Gate Valves, Flanged – Butt Weld End. SALIENT FEATURES: Body & Bonnet made from high quality casting with liberal sections. The castings are precision machined for high performance Bi-Directional Shut-Off Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature. Deep stuffing box is providing for tightness and maximum long packing life. Swinging Eye Bolts facilitate easy access to the stuffing box. Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position. Seat Ring Screwed in to the body are replaceable type. Seal welded type Seat Ring & Integral Seat cab also be offered on special request. Stellited Wedge (Gate), Seat Ring & Back Seat can also be offered on special request. Higher Pressure & Higher Size Valves are provided with Thrust Bearings and also with Gear drive arrangements. In built wear life for long duration of service. Material of Construction: Cast Iron : IS 210 Gr FG 200Cast Carbon Steel : ASTM A 216 Gr WCBCast Stainless Steel : ASTM A 351 Gr CF 8/CF 8MForged Carbon Steel : ASTM A 105Forged Stainless Steel : ASTM A 182 Gr F304 / F316End Connection : Screwed AS PER BSP/BSPT/NPTSocketweld : AS PER ANSI B 16.11Flanged : AS PER ANSI B 16.5Pressure Rating : ASA 125#, 150#, 300#, 600#, 800#Engineering Option : Gear Operated, Electrical Actuated,Size Range : 15 mm to 300 mm DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : API 600 / API 602 / API 603 / IS 780 / BS 14846Pressure Testing : API 598Face To Face : ANSI B 16.10Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392Butt Weld End : ANSI B 16.25Socket Weld End : ANSI B 16.11Screwed End : ANSI B 1.20.1(BSP/NPT) Applications:- Fire Protections. Water Piping’s. Wastewater Treatment Water Distribution Pipeline manymore.. SPECIAL OPTIONS Extended Bonnet design for low temperature and cryogenic services. Flexible / Solid Wedge / Double Disc Type Bolted Bonnet / Pressure Seal Bonnet Gear / Pneumatic Cylinder / Hydraulic Cylinder / Electrical Actuator Operated Locking Arrangement With NACE MR 0175

...more

Four Way Ball Valves

JD Multiport Ball Valves are ideally used for flow diverting or mixing application. There can be one inlet & multiple outlets & vice versa JD Controls Four Way Ball Valves is a fluid control valve. Types 1] L Port 2] T port 3 ] “LL” [X] Port. it has four ports equally spaced round the valve chamber and the ball has two passages to connect the adjacent ports.It has two flow positions as shown, and usually a central position where all ports are closed. APPLICATION OF 4 WAY BALL VALVE:- Air Dryers CO2 Dryers LPG Compress ADVANTAGES Multiple no of valves can be replaced by few no of valves. Reduced Labour& Maintenance cost Space saving Flow diversion or Mixing can be more precise. AVAILABILITY Size : – DN25/25mm/One Inch1” To DN300/300mm/ Twenty Four Inch 12” MC : – WCB/CF8(SS304)/CF8M(SS316)/CF3(304L)/CF3M(316L) Pre class: – 150# / 300# / 600# / 900# Operation: – Manual/Pneumatic/Electrical End connection: – Flanged End & Screwed End Valve Design:- BS5351/ANSI B 16.34/ API 6D Pressure Testing:- BS 6755 Part II/API 598/API 6D Fire Safe Testing:- BS 6755 Part II API 607/ API 6FA Ends:- S/E(Screwed End)[BSP/NPT-F],SW & F/E(Flanged End) SALIENT FEATURES: High Performance Ball Valve Longer Life Positive Shut off Quick in Action No Lubrication Compact Design Low Pressure Drop Simplicity DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 / API 6DPressure Testing : BS 6755 Part II / API 598 / API 6DFire Safe Testing : BS 6755 Part II API 607 / API 6FA /Face To Face : ANSI B 16.10Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392Butt Weld End : ANSI B 16.25Socket Weld End : ANSI B 16.11Screwed End : ANSI B 1.20.1(BSP/NPT) MATERIAL OF CONSTRUCTION: Body / End Connector Piece: Cast Iron to ASTM A 126 Class B IS 210 GR. FG 200 / 220 / 260Ductile Iron to ASTM A 536 Grade 65-45-12Cast Carbon Steel to ASTM A 216 GR. WCBStainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3MHast Alloy B / CASTM A 351 GR. CN 7M (Alloy 20) Ball: Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3MHast Alloy B / CASTM A 351 GR. CN 7M (Alloy 20) Stem: AISI 410 (S.S. 410 13% Cr. Steel)AISI 304 (S.S. 304)AISI 316 (S.S. 316)AISI 304L (S.S. 304L)AISI 316L (S.S. 316L)Hast Alloy B / CAlloy 20 Ball Seat / Gland Seal / Stem Seal P.T.F.E. VirginP.T.F.E. Glass FilledP.T.F.E. Carbon FilledGrafoil

...more

FORGED STEEL HIGH PRESSURE BALL VALVE

J. D. Controls manufacturing High performance Forged Steel Ball Valve as per international design and standard to get 100% Client Satisfaction and repeat order with total interchangeability, superior quality, workmanship & service. These Ball Valves come in Three Piece Design (1/2 to 2) to suit various critical, non-critical applications and pressure rating up to 800 class in regular (reduce) bore design. J D P.T.F.E. seated Forged Steel Ball Valve gives Zero Leakage, Tight Shut-Off and Low Torque with easy smooth operation at temperature ranging from -20° C. to +220° C. Electro-Polished, Buff Finish & Ultra clean valve also provided for Food & Pharmaceutical Industries on request. WIDE RANGE OF BODY SEAT, SEAL & PACKING: J D Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) / PEEK to suit special requirement of client. DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 Pressure Testing : BS 6755 Part II / API 598 Face To Face : ANSI B 16.10 Butt Weld End : ANSI B 16.25 Socket Weld End : ANSI B 16.11 Screwed End : ANSI B 1.20.1(BSP/NPT) SALIENT FEATURES: High Performance Ball Valve Longer Life Positive Shut off Quick in Action No Lubrication Compact Design Low Pressure Drop Simplicity

...more

Forged Steel Globe Valve

DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5352 Pressure Testing : BS 5146 Face To Face : ANSI B 16.10 Butt Weld End : ANSI B 16.25 Socket Weld End : ANSI B 16.11 Screwed End : ANSI B 1.20.1(BSP/NPT) SALIENT FEATURES: Body & Bonnet made from high quality forging. The Forgings are precision machined for high performance Leak Proof Body-Bonnet Joint With Spiral Wound Gasket Rising Stem & Rising Hand Wheel Construction. Ground Finish Stem Self Aligning Two Piece Gland Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature. Precision Stem Packing Chamber Deep stuffing box is providing for tightness and maximum long packing life. Swinging Eye Bolts facilitate easy access to the stuffing box. Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position. Stellited Disc, Seat Ring & Back Seat can also be offered on special request.

...more

Forged Steel Gate Valve

J. D. Controls Forged Steel Gate Valves are Bolted Bonnet, outside screw and yoke type, Rising Spindle construction Body and bonnet made from high quality forgings. J. D. manufacturing Forged Steel Gate Valves in size 1/2 (DN15) to 2 (DN50) to suit various critical, non-critical applications and pressure rating up to 1500 class in Regular (Reduce) bore & Standard (Full bore) design. DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : API 602 / BS 5352 Pressure Testing : API 598 / BS 5146 Face To Face : ANSI B 16.10 Butt Weld End : ANSI B 16.25 Socket Weld End : ANSI B 16.11 Screwed End : ANSI B 1.20.1(BSP/NPT) SALIENT FEATURES: Body & Bonnet made from high quality forging. The Forgings are precision machined for high performance Leak Proof Body-Bonnet Joint With Spiral Wound Gasket Bi-Directional Shut-Off Ground Finish Stem Self Aligning Two Piece Gland Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature. Deep stuffing box is providing for tightness and maximum long packing life. Swinging Eye Bolts facilitate easy access to the stuffing box. Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position. Stellited Wedge (Gate), Seat Ring & Back Seat can also be offered on special request.

...moreBe first to Rate

Rate ThisOpening Hours