V-Return Idler

Where return idler sets comprise two rolls, a support frame is required which supports the idler pair and attaches the idlers to the conveyor frame. This 2-roll design forms the return belt into a 'v' trough and these return idler sets are referred to a 'V' return idlers. The trough angle of the 'V' return idler is usually 10 degrees and this feature has been developed to assist with belt training along the return strand

...more

UHMW-PE Rollerr

UHMWPE is an outstanding plastic with the best self lubrication, impact absorbing properties and the highest resistance to abrasion, impact and chemicals of any thermoplastics polymer. It is regarded as an amazing material, and the new material will grow fast and be widely used Features : Abrasion and Chemical resistance Impact resistance and Impact energy absorbing Water proof and dust proof. Light weight and energy saving Reduced belt damage Noise reduction Long Life Could not be sticked by any material.

...more

Troughing Impact Idler

Troughing Impact Idler are Used under loading points where material impact (lump size,density, height) could damage the belt if no cushion. Impact Idlerfitted with rubber rings made from natural / Synthetic / Neoprene material. The fixing arrangement and dimension of rings are suitably design for easy replacement and interchange ability which protect the belt by absorbing impact at loading point. 20º, 35º and 45º Trough Angle

...more

Take-Up(Tail) Pulley

Pulley, which can be moved to keep belt tight, is called take-up Pulley.Take-Up Pulley may be a drive pulley or an idler pulley

...more

Superior Abrasion Resistant Conveyor Belt

We are a prominent manufacturer, supplier and exporter of superior abrasion resistant conveyor belting, that find application in airports, shipyards, thermal power plants and various other industries. Engineered with utmost precision, these conveyor belts are widely used for the transportation of glass, cullet, granite, trap rock and other abrasive materials Features :Dimensionally accurate and functionally superior, these abrasion resistant conveyor belts are used for moving bulk product from production to storage and storage to production. Optimization of premium quality rubber makes these conveyor belts flawless in performance. We also entertain the clients’ queries and customize these belts as per their specific requirements. Belt covers compounded from super abrasion rubber Resistance to water High elasticity Heat resistant

...more

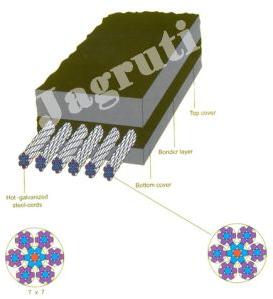

Steelcord Conveyor Belt

Steelcord Conveyor Belt have proved to be a very Reliable and Cost – efficient mode of Bulk Material Handling in Long Distance Conveyors. The Core Element: STEELCORD The Cord used in Jagruti Steelcord belt is made of specially developed High Carbon Steel. During manufacturer of Belt, these cords are held longitudinally in a single layer under pre-determined tension to ensure proper alignment. The Cords are Zinc coated to ensure superior bonding between Cord and Rubber as well as to protect the same against corrosion. The Cords may have several types of configurations like 7 x 7, 1 x 19 + 7 x 7, 7 x 19 etc. The Steel Cords, unlike free-running cable, do not need any lubrication. Hence the core is not a lubricant but an additional reinforcement. Under load, the cords do not tend to creep. The Cover Element: COVER RUBBER The Cover Rubber which acts as the protective for the Steel Cords is specially developed with high Tensile Strength, high Elongation at Break, maximum resistance to tear propagation and low Abrasion loss. Further, it is designed to meet specific Application Requirement like General Purpose Super Abrasion Resistance Fire Resistance Heat Resistance Chemical Resistance The Bonding Element: BONDER RUBBER Advantages : Higher speed, Runs straight, Needed little maintenance, Long life, High Tensile Strength, Smaller Pulley Diameter, Excellent Troughability, Low elongation, Heat Cold or moisture do not affect the running behavior

...more

Special Customized Conveyor Belt

15. Special Customized Conveyor Belt These belts are designed to provide the major advantages for trouble free service life and have the following advantages like High Adhesion, level, higher ply strength and lower self weight, improved utilization, outstanding impact resistance, elimination of edge protection & higher longuidinal flexing. Jagruti Endless Belt (Joint less Belt) ‘Jagruti’ endless belt without splice joint (Joint less Belts) are manufactured directly in “Sleeve” form as per customer’s requirement. The basic advantage is that, it has no transversal or longitudinal joints. Joint less belts have been highly acclaimed especially when they are used as feed belts on the system such as conveying, gauging, die cutting, dosing and weighing, squaring, stretching bag filling, packaging etc. Joint less belts provides more life then splice joint vulcanized belt. Jagruti “Y” CLEATS BELTS The “Y” chevrons with height of 20 mm are obtained by direct vulcanization on the belt top. It permits conveyance on slopes even stepper than 40’ depending on the type of material being conveyed. This belts is particularly suitable for non-stop application, in cement, fertilizers, chemical, steel rolls industries etc. Used for zero spillage, fast and bulk material handling. Suitable for high inclination & magnet separator. Use to carry materials on steeper angle up 90’ with no spillage space requirement is quiet less as compared to conventional belts. Jagruti Checkared Belt Jagruti’ Checkared belt with “V” section pulley guide single or multiple guides of “V” section directly vulcanized on to the bottom cover of the belt, ensure a perfect straight running line and resist to transverse impulses eventually applied to the bottom mainly used for bag diverters or weigh feeders. Jagruti Embossed Belting/ High Grip Type / Rough Top These surface are obtained by direct vulcanization of the belts top cover by using special moulds, Due to high inclination belts carrying flat packages could have slide inclination back problems, grip surface belts with profile, are offered for such applications. Jagruti Widerendless Belts These belts are also ideal for precision indexing of goods, good shock absorption properties & choice of PVC or nitrile rubber surfaces in range of deep-embossed pattern. "More information please visit our site www.jrepl.com"

...more

Solid Rubber Tyres

Used for making raised cleat conveyor belts, which are suitable for transportation of firewood, hay, glass, recycled materials, packaged goods and boxes at an inclined angle. According to its operational requirement and size, the shape and pitch of the rubber side wall can adequately be made.

...more

Solid Rubber Tyre

Jagruti Solid Rubber Tyres are manufactured for various types of sensor paver machine, Forklift and various types of trolleys. Solied Tyres are available with plate and with hub. Solid Tyres provides excellent performance in antiwear, high flexibility, Independent pattern design offers superior scratch & anti sideslip performance. Solid Tyres offer longer operational life and are least expensive.

...more

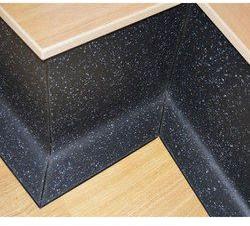

Skirting Rubber

Skirting rubber is a general purpose rubber used mainly in the mining industry as a side skirt on conveyor belt systems to prevent the materials falling down. It is available in full width slabs up to 2000 mm wide and also pre-cut skirting strips A general purpose grade of natural rubber used for many quarrying and mining applications in dust and spillage control. A softer grade natural rubber, with good tensile and elongations properties, it is ideally suited for conveyor skirting applications where belting wear is of concern. The rubber is also used where a flexible, but abrasive resistant seal is required.

...more

sidewall belt

These technically advanced side wall conveyor belts ensure fast and safe movement of powdery and lumpy material even in bulk quantity. The belts are manufactured using high quality raw materials and thus are able to work in extreme temperatures as well as do not buckle under compression. Widely used in various industrial applications, these conveyor belts are offered at competitive rates. Can be used at steeper angles up to 75 degree, Ideal for transporting powdery and lumpy materials, Can transport high volumes without any spillage, Are adequately rigidity, Do not buckle under compression, Tear and gauging resistance, Enhanced durability.

...more

sidewall

Used for making raised cleat conveyor belts, which are suitable for transportation of firewood, hay, glass, recycled materials, packaged goods and boxes at an inclined angle. According to its operational requirement and size, the shape and pitch of the rubber side wall can adequately be made.Remarks: for more details, please contact us!

...more

Self- Training Carrying Idler

Self-Training Flat Return Idler automatically trains the belt from misalignment and protects the belt edges from damages caused by the same. The action is positive for belt operations.Used to correct belt misalignment on the return side.

...more

Rubber Skirting

Skirting rubber is a general purpose rubber used mainly in the mining industry as a side skirt on conveyor belt systems to prevent the materials falling down. It is available in full width slabs up to 2000 mm wide and also pre-cut skirting strips.

Width : 2,000 mm

Thickness : 50 mm

...more

Rubber Sheet

Range of Rubber Sheet :- The prominent range of "Jagruti" Rubber sheet are pure rubber sheeting, skirt-board, Rubber insert on sheeting, gum sheeting chuteing, hospital sheeting, sponge sheet foam sheet, pulley aging sheet, impression sheet, rubber sed cork sheet, batata sheet. • Thickness range from 0.5mm to 100mm. • Width 1220mm (48") in continuous length n smoothly glossy finish both side fabrics impress on finish • Colour any colour per your specific requirement. • Insertion sheeting with one or two / multiple plies are also available special purpose rubber sheet available on customize basis. • Special Note: we can manufacture special purpose rubber sheet up to 2000mm width. Characteristic Natural rubber / SBR : Having good mechanical properties and weather resistance. Chloroprene : Excellent weather resistance and mechanical properties. NBR : Excellent resistance to oil and fats. EPDM : Excellent weather, steam resistance. Sillicon : Excellent oil and fats resistance and for high temperatureup to 200° C. Viton : For high temperature up to 300° C.

...more

Rubber Conveyor Belt

With a wide range, to suit almost all the Industries, light duty industrial conveyor belts are manufactured with various base fabrics like polyester, nylon, cotton, solid woven, fibre glass etc. and top surface coating with Rubber/PVC/PU/Silicon. These belts are available in White, Green, Black or any other color according to specific requirement, up to 2400 mm wide. Low operating noise & costs, reduced maintenance, excellent durability. - Largely impervious to oils, greases and many chemicals. - Special types give excellent grip on inclines. - Abrasion resistant - Rugged. - High strength - Low stretch characteristic. - Light & thin, better strength/weight ratio - energy saving. - Superb tracking over great length- longitudinally flexible & laterally stiff. - Antistatic - prevents electrostatic build-ups. - Can be fitted with flights, profiles & sidewalls. - Wide ranges of availability in 1,2,3 ply construction & solid woven. - Simple thermo jointing finger or spliced, and can be done at site even. Application Areas: - Packaging, Pharmaceuticals, automotive industry, sorting & baggage handling, baking, biscuit & tiles making, caning treadmills, fruit & vegetable handling fish processing, glass & insulation.

...more

Return Roller

The straight tracking of the belt may be compromised by the type of conveyed material, especially when this material is sticky and thereby adheres easily to the belt surface. In this case, material is also deposited on the return rollers that support the belt, adding an irregular addition of scale to the roller itself. Features : As a consequence, not only wear and tear of the belt occurs, but forces are brought into play to move the belt away from its correct track. Return rollers with spaced rubber rings contribute largely to eliminating the build up of scale that forms in certain conditions on the belt surface. The rings are pointed, assembled at intervals, in the central part of the roller, where they have the scope to break up the scale which normally is present at the belt centre; meanwhile flat rings mounted in groups at the extremities of the belt, support and protect the belt edges, also in cases of limited belt wandering. Return rollers with rings should not be used as belt tensioning devices.

...more

PVC sidewall bel

Product Description: Using the latest state of the art equipment a variety of transverse cleats can be fitted to any base belt. Tensile strength: 80-300N/mm Temperature range: -10 ~+90 degree Specification, color and thickness according to the requirements of clients.

...more

PVC Conveyor Belt / Light Duty PVC Belt

The Core Element: STEELCORD With a wide range, to suit almost all the Industries, light duty industrial conveyor belts are manufactured with various base fabrics like polyester, nylon, cotton, solid woven, fibre glass etc. and top surface coating with Rubber/PVC/PU/Silicon. These belts are available in White, Green, Black or any other color according to specific requirement, up to 2400 mm wide. Features : Low operating noise & costs, reduced maintenance, excellent durability. Largely impervious to oils, greases and many chemicals. Special types give excellent grip on inclines. Abrasion resistant – Rugged. High strength – Low stretch characteristic. Light & thin, better strength/weight ratio – energy saving. Superb tracking over great length- longitudinally flexible & laterally stiff. Antistatic – prevents electrostatic build-ups. Can be fitted with flights, profiles & sidewalls. Wide ranges of availability in 1,2,3 ply construction & solid woven. Simple thermo jointing finger or spliced, and can be done at site even.

...more

PVC Chevron belt

Product Description : A range of chevron patterns can be customized to suit your specific requirements. Tensile strength: 80-300N/mm Temperature range: -10 ~+90 degree Specification, color and thickness according to the requirements of clients. The salient features of the belt are: Longer working life Can carry loose materials at angle of 17-18 and bagged material at 30-35 Cleat angle and pitch are designed for smooth travel over return idlers Cleats and the top cover rubber are mono block molding for strength

...more

pvc belt

With a wide range, to suit almost all the Industries, light duty industrial conveyor belts are manufactured with various base fabrics like polyester, nylon, cotton, solid woven, fibre glass etc. and top surface coating with RubberPVCPUSilicon.These belts are available in White, Green, Black or any other color according to specific requirement, up to 2400 mm wide.

...more

Pulley Lagging Sheet

Conveyor Belt when slips cause significant damage to the drive pulley and the belt. Such damages are not only expensive to repair, but also time consuming and cause enormous loss due to down time., The life span of a conveyor system primarily depends on its being suitably equipped for the specific application and the standard of servicing and maintenance. The conveyor systems often have to perform in the most difficult conditions.

...more

Power Transmission Belts

Pipe Conveyor Belt

Pipe conveyor belt is a new type of conveying belt which uses belt carcasses (EP fabric, Steel cord etc.)as skeleton and high elastic, high anti-abrasive and high strength rubber as working surface. They are mainly used in conveying powdery and granular materials etc. that pollute the environment. When working, the rubber belt changes its form from flat to U shape and finally to pipe shape, folding the materials and realizing the process of enclosed conveying. Closed transportation in order to prevent materials from overflowing ,drop-down, scattering and mixing with foreign materials from outside. This pipe conveyor belt is economical for curve(45°-90°) and incline(up to 30°) transportation due Enclosed conveying of materials thus is protecting the environment.

...more

Conveyor Belt Jointing / Steel Cord Jointing

We are fully equipped by means of adequate latest Machineries, Team & Experts on Hot Vulcanizing and Cold Vulcanizing of Conveyor belts & Rubber Lining of Vessels and Pipes, Rubberisation of Rollers & Drums, Endlessing & Repairing of Conveyor Belts at site. We also undertake annual job Contracts for Conveyor Belt Joining, Steel Cord Jointing, Pulley Lagging, Rubber lining in tanks etc. Modify/Servicing of Conveyor system in our sister concern company M/s. JAGRUTI RUBBER ENTERPRISE.

...moreBe first to Rate

Rate ThisOpening Hours