Jaw crusher

Get Price Quote

Double Toggle Jaw Crusher

Get Price Quote

Umatech Micron is one the leading manufacturer and supplier of jaw crushers for the processing & quarrying industries. For primary crushing of medium-hard to very hard material in a bigger size like natural stone/boulder , Umatech Micron offers a wide range of efficient and proven single –toggle (grease-type) and double-toggle (oil-type) jaw crushers.Features & Benefits: Their long life service due to robust construction and a best possible and uniform stress distribution, ascertain by means of the finite element analysis. High through put (production) rate owing to an optimised geometry of the crushing chamber. The deep Jaws provide for a large feed opening with a small nip angle giving increased crushing efficiency and high capacity. Large Cast Flywheels with thick rims provide high inertia. Large Spherical roller bearings protected by a combination of lybrinth and vee-ring seals. Easy mechanical gap adjustment. Heavy duty spherical roller bearing with greasing facilities. Crushing jaws made of high grade (12-14%) Mn steel, check plates made of high strength special steel.

Best Deals from Jaw Crusher

Jaw crusher

Get Price Quote

We are the established manufacturer and supplier ofJaw Crusher.

Pe Jaw Crusher

Get Price Quote

PE series jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder making plants. It can be described as obbligato machine in mining, building construction, construction wastes crushing, Hydropower and Water Resource, railway and highway construction and some other industries.

Jaw crusher

500,000 - 5,000,000 Per set

15 Set (MOQ)

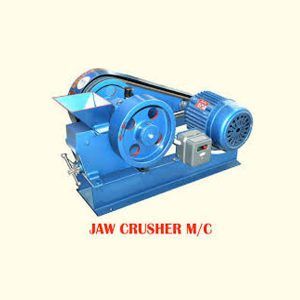

Jaw Crusher Laboratory Type

Get Price Quote

Max size of feed 50mm (approximately) product discharge size of feed 6mm to 18mm (adjustable) capacity 80kghr (approximately - based on material) operation on 440 volt, 3 phase, 50hz, a.c. Supply with 3h.p. Electric motor motor, a starter ' v ' belt pulley drive and mounting

Single Toggle Jaw Crusher

Get Price Quote

single toggle jaw crushers are used for primary crushing. Single toggle jaw crusher is designed for exceptionally heavy and continuous applications. single toggle jaw crushers are provided in heavy and light versions with welded steel housing and a moving jaw in a welded or cast steel version, as well as an eccentric shaft made of high-grade forged steel. features and benefits high and constant capacity. high operational reliability. heavy duty forged crank shaft. broad range of application. easy replacement of wear and spare parts.

Jaw Crusher Laboratory

Get Price Quote

Introduction Laboratory Jaw Crusher is designed to speed up the crushing of aggregate, ores, minerals, coal, coke, chemicals and other similar materials. Its compact and of rugged construction is advantageous for general laboratory or small pilot plant operations.wo jaws of manganese steel are provided in the jaw crusher. The moveable jaw produces two blows for every revolution, thus reducing over sizing to a minimum. A combination of forward and downward and strokes with a rocking action exerts pressure on the coarse material to pass through the jaws. A hopper is provided at the top for feeding materials. The smooth jaws ensure a uniform product and easy cleaning is possible. Max Size of feed 50mm (approximately) Product discharge Size of feed 6mm to 18mm (adjustable) Capacity 80kG/hr (approximately - based on material) Operation On 440 volt, 3 Phase, 50hz, A.C. supply with 3H.P. Electric motor motor, a starter ' v ' belt pulley drive and mounting

Jaw crusher

Get Price Quote

Scanner Machine, rotary furnaces, indus industrial boiler